Difference between revisions of "CNC Bender v12-20100820"

From ATTWiki

| Line 107: | Line 107: | ||

Background Read Servo Loop Interval=0.100 | Background Read Servo Loop Interval=0.100 | ||

</pre> | </pre> | ||

| + | |||

</td> | </td> | ||

</tr> | </tr> | ||

| Line 112: | Line 113: | ||

<tr valign=top> | <tr valign=top> | ||

<td width=300> | <td width=300> | ||

| + | These items are removed from the configuration file ---> They are no longer used in CNC Processor. | ||

</td> | </td> | ||

<td> | <td> | ||

| + | <pre> | ||

| + | [Loop] | ||

| + | Power Off Manual Mode Pause=250 | ||

| + | Power On Manual Mode Pause=250 | ||

| + | Cycle Hold Pause=100 | ||

| + | |||

| + | [PRIORITY] | ||

| + | Master Loop Priority=10000 | ||

| + | </pre> | ||

</td> | </td> | ||

</tr> | </tr> | ||

Revision as of 22:58, 20 August 2010

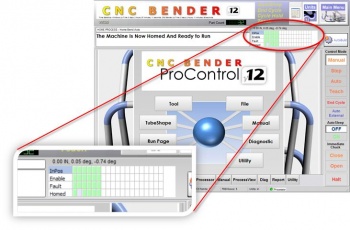

NEW - Servo Status Grid Now Always Visible on Main Screen

NEW - Servo Status Grid Now Always Visible on Main Screen

|

The status of up to 20 servo axes are now displayed at all times in a small grid on the main page. Whenever the states change, the grid cells color changes to either grey, green, or red. |

|

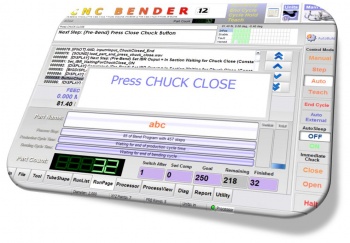

NEW - BIG Messages

NEW - BIG Messages

|

For important events, CNC Bender now displays large messages for short periods of time. This lets operators clearly know what the control needs them to do next.

|

|

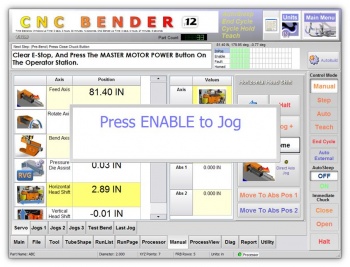

NEW - Press ENABLE to Jog

NEW - Press ENABLE to Jog

CHANGES - CNC Processor Configuration File

CHANGES - CNC Processor Configuration File

|

The following additions have been made to the configuration file:

|

[Smart Inspect Logging] Enabled=0 Logging Method=TCPIP Filename=c:\cnc\logs\cncprocessor.sil TCPIP Address=192.168.0.190 [Loop] Main Loop Interval=0.100 Background Read Servo Loop Interval=0.100 |

|

These items are removed from the configuration file ---> They are no longer used in CNC Processor. |

[Loop] Power Off Manual Mode Pause=250 Power On Manual Mode Pause=250 Cycle Hold Pause=100 [PRIORITY] Master Loop Priority=10000 |

Other Pages

- Back to CNC Bender

- Back to CNC Bender Software Updates

- See CNC Bender General Information

- See Teach Mode

- See Custom Commands