Difference between revisions of "D of Bend"

(→How Is It Used?) |

(→Examples) |

||

| Line 16: | Line 16: | ||

==Examples== | ==Examples== | ||

| − | In many applications, lower D of bend valued radii. | + | In many applications, a lower D of bend valued radii is more esthetic. But it is harder to bend, and therefore more expensive. |

| − | + | *D of bend = 2.00 is generally considered not too complex. | |

| + | *D of bend = 1.50 is moderately difficult. | ||

| + | *D of bend = 1.00 is difficult. | ||

| − | + | D of bend values below 1 are possible - but are very rare and require special benders that can press material into the bender's dies. (Most call this "carriage boost".) For example, it is possible to achieve 0.75 D of bend - but at a much higher cost. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

==Import After Fix== | ==Import After Fix== | ||

Revision as of 15:18, 2 January 2020

- Back to VTube-STEP or VTube-LASER

Contents |

What is D of bend?

Tube fabricators sometimes indicate the centerline radius using D of bend.

We say it by speaking three words: "D of bend".

Some tube fabricators also say "D factor" to mean the same thing.

It is a ratio calculated like this: D of bend = Centerline Radius / OD

How Is It Used?

FABRICATORS: The D of bend value helps fabricators know if the radius is tight or large compared to the OD. It serves as a general guide for how difficult it will be to create a quality bend. It helps fabricators know what kind of tooling will be necessary to achieve the bend. It is useful, therefore, in building quotations for customers.

DESIGNERS: It is also helpful for designers as a limit for what is practical.

Examples

In many applications, a lower D of bend valued radii is more esthetic. But it is harder to bend, and therefore more expensive.

- D of bend = 2.00 is generally considered not too complex.

- D of bend = 1.50 is moderately difficult.

- D of bend = 1.00 is difficult.

D of bend values below 1 are possible - but are very rare and require special benders that can press material into the bender's dies. (Most call this "carriage boost".) For example, it is possible to achieve 0.75 D of bend - but at a much higher cost.

Import After Fix

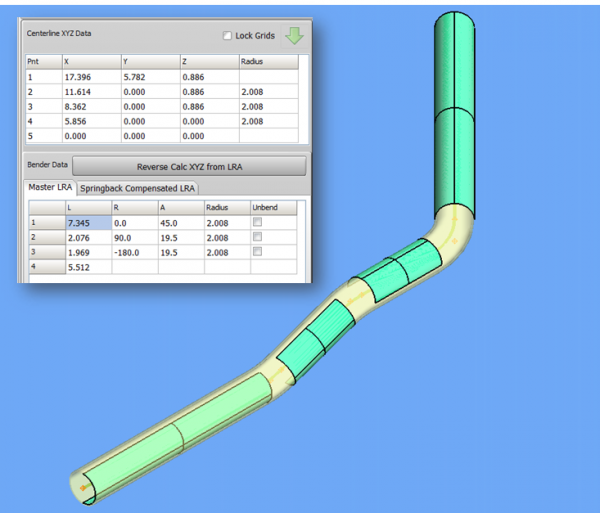

This is how the imported part shows now: