Difference between revisions of "Benderlink for FARO"

From ATTWiki

| Line 5: | Line 5: | ||

__NOTOC__ | __NOTOC__ | ||

| + | <table> | ||

| + | <tr> | ||

| + | <td> | ||

| + | [[image:blinkfaro_mainscreen.jpg|450px]] | ||

| + | </td> | ||

| + | <td> | ||

[[image:Faro_logo.jpg|right]] | [[image:Faro_logo.jpg|right]] | ||

| − | [[image:Win_xp_logo.jpg | + | [[image:Win_xp_logo.jpg|125px]] |

| − | [[image:Win_vista_logo.jpg | + | [[image:Win_vista_logo.jpg|100px]] |

| + | </td> | ||

| + | </tr> | ||

| + | </table> | ||

| − | |||

<br> | <br> | ||

Revision as of 02:39, 4 February 2009

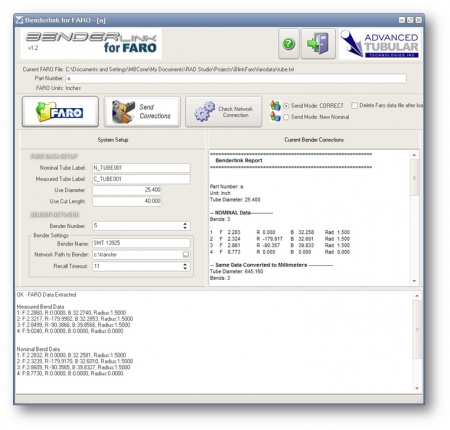

Benderlink for FARO software connects FARO arms using FARO CAM2 software to tube bending machines using the SVNET protocol.

How it Works

- Acts as a Supravision-based measuring center in a bender network using the SVNET protocol.

- Uses FARO Inspection Report data to send NEW data to benders, or CORRECT existing data.

- Stores a persistent network of benders - Each bender can have its own unique settings (as of v1.2)

Software Updates

| Screen Shot | Date Released | Link to Page | New Features |

|

April 22, 2009 | Benderlink for SolidWorks 2.0 |

|

|

April 4, 2009 | Benderlink for SolidWorks 1.9 |

|

| March 24, 2009 | Benderlink for SolidWorks 1.8 |

|

|

| March 10, 2009 | Benderlink for SolidWorks 1.73 |

|

|

|

March 7, 2009 | Benderlink for SolidWorks 1.71 |

|

FARO Compatibility

- Software Tested: FARO CAM2 Measure Version 4.0.5.2.

- Arm Tested: Advantage FaroArm

Bender Compatibility

- Benderlink for CNC Bender (SMT)

- Benderlink for Chiyoda / KEINS

- Benderlink for Flexbender (Wayne Trail Technologies)

- Benderlink for MiiC

- Benderlink for AMCS

- Benderlink for BLM

- Benderlink for Crown

- Benderlink for Addison to Romer

- This software is capable of connecting and correcting any bender that uses the Supravision Network protocol. This includes:

- All Advanced Tubular controlled CNC Benders

- All CurrentTech controlled CNC benders

- All TS-2000 PINES Benders

Features

- Loads XYZ export files created by CAM2

- Accepts drag and drop FARO files

- Checks for the proper FARO file format while loading

- The CAM2 export file can contain multiple tube constuctions from measurements and multiple nominal constructions, so Benderlink allows

the operator to indicate which tube shape is to be used as measured and which is to be used as nominal.

- Choose to send nominal data as NEW data to connected benders or...

- Choose to send measured data as NEW data (for reverse engineering) or...

- Choose to send correction data to the bender.

- Bend radius, cut length, and diameter is transferred when NEW data is sent to the bender

- Connection to benders uses the SVNET protocol. Benderlink acts as a client measuring center. Benders respond using the standard SVNET protocol.

- True corrections are handled within a few seconds. Data recall does not occur until after the decision to send corrections to the bender. During a correction, the operator station data is recalled, corrections are made, then the data is sent back to the operator station within a few seconds.

- The bender number to call is programmable (from 1 to 99)

- The recall timeout is programmable in seconds (1 and up)

- Values programmed into the software are saved to a configuration file for use next time Benderlink is loaded.

- Quickly check the quality of the network connection using a "Check Network Connection" button.

- Long route rotation settings are preserved during correction.

- The current FARO filename, part number, and units are displayed at the top of the Benderlink window after the XYZ file is loaded

- The current bender data for the NOMINAL values are displayed in a updated report log. The data is displayed in both inch and millimeter

units at the same time.

- The current bender data for the MEASURED values are displayed in an updated report log. The data is displayed in both inch and millimeter units at the same time.

- If both NOMINAL and MEASURED tube sections are found and extracted from the FARO CAM2 data, then the updated report log also displays the CORRECTION values that will be applied if the operator sends corrections to the bender.

- Special scenario warning: Warns if a correction is about to be sent a second time without also loading new FARO data into the software. This

helps prevent accidental accumulations to the bender values.

- Special scenario warning: Warns if data must be sent as NOMINAL data only, then gives the choice of stopping the transfer.

- A status log is displayed at the bottom of the screen to show special messages regarding the state of the transfer.

- Sound is used to indicate the start of transfers and the completion of transfers. A successful transfer announces "Your transfer is completed."

- In addition to sound, dialog windows are used to display information about important events occurring - like transfers of data to benders.

PDF DataSheet

|

Download a DataSheet for Benderlink for FARO |

OTHER PAGES

- Back to Benderlink