Difference between revisions of "Benderlink for CNC Bender"

(→Software Updates) |

|||

| (110 intermediate revisions by one user not shown) | |||

| Line 1: | Line 1: | ||

| + | <table> | ||

| + | <tr> | ||

| + | <td width=100> | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:Cncblink_logo.jpg|500px]]<br> | ||

| + | [[image:vtube-laser_v2.2_cncbender_benderlink.png|500px]] | ||

| + | </td> | ||

| + | <td> | ||

| + | </td> | ||

| + | </tr> | ||

| + | </table> | ||

| − | + | __NOTOC__ | |

| − | + | ==Description== | |

| − | + | ||

| − | + | <table> | |

| + | <tr> | ||

| + | <td width=300> | ||

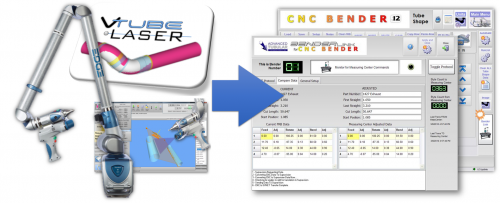

| + | Benderlink is designed to make a connection between CNC Bender and measuring centers to allow measuring centers to steer the bender to the correct part shape quickly. | ||

| + | <br><br>Combine the ProControl Benderlink with our world-class [[VTube-LASER]] software on a [[FARO]] arm to make measuring tubes easier than ever. | ||

| + | </td> | ||

| − | + | <td> | |

| + | [[image:Cncblink_mainscreen.jpg|400px]] | ||

| + | </td> | ||

| + | </tr> | ||

| + | </table> | ||

| − | + | ==Features== | |

| − | + | <table width=700> | |

| + | <tr> | ||

| + | <td width=150> | ||

| + | '''POWERFUL COMPARE and APPROVE''' | ||

| + | </td> | ||

| + | <td> | ||

| + | Benderlink for CNC Bender ProControl v14 is one of the most powerful versions of Benderlink available in any CNC bender software package with the new COMPARE feature. | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:cncv12_blinkcompare.jpg|250px]] | ||

| + | </td> | ||

| + | </tr> | ||

| + | |||

| + | <tr> | ||

| + | <td> | ||

| + | '''BUILT-IN INDUSTRY STANDARD PROTOCOLS''' | ||

| + | </td> | ||

| + | <td> | ||

| + | Protocols supported directly are: Our [[VTube-LASER]] (FARO), Supravision Network Protocol (ROMER) and Eaton Leonard Vector Tube Data Center | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:faroedge_scanarm_hdscanner.png|125px]][[image:Romer_infinite.jpg|125px]][[image:Vector_tube_data_center.jpg|125px]] | ||

| + | </td> | ||

| + | </tr> | ||

| + | |||

| + | <tr> | ||

| + | <td> | ||

| + | '''SMART BEND COMBINATION''' | ||

| + | </td> | ||

| + | <td> | ||

| + | Benderlink automatically combines bends for the bender that should be combined. | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:cncv12_autocombinefeature.jpg|250px]] | ||

| + | </td> | ||

| + | |||

| + | </tr> | ||

| + | |||

| + | <tr> | ||

| + | <td> | ||

| + | '''SMART SPLIT BEND''' | ||

| + | </td> | ||

| + | <td> | ||

| + | Benderlink automatically splits bends for the measuring center that should be split. | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:cncv12_autocombinefeature.jpg|250px]] | ||

| + | </td> | ||

| + | </tr> | ||

| + | |||

| + | <tr> | ||

| + | <td> | ||

| + | '''SMART NEW PART DETECTION''' | ||

| + | </td> | ||

| + | <td> | ||

| + | Benderlink automatically detects when the part data is new versus when the part data is an existing setup that should be corrected. | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:cncv12_sendnewfromvector.jpg|250px]] | ||

| + | </td> | ||

| + | |||

| + | </tr> | ||

| + | |||

| + | <tr> | ||

| + | <td> | ||

| + | '''CLEAR ACTIVITY FEEDBACK''' | ||

| + | </td> | ||

| + | <td> | ||

| + | With our Benderlink you can know for sure that data was transferred. You can even see when it was transferred - in either direction.<br><br> | ||

| + | |||

| + | Benderlink helps you know that communications are active by display LED counters with the exact byte count sent or received.<br><br> | ||

| + | |||

| + | The "Last Trans" labels let you see when the last transfer occurred. | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:cncv12_blinkledcounters.jpg]] | ||

| + | </td> | ||

| + | |||

| + | </tr> | ||

| + | |||

| + | |||

| + | |||

| + | </table> | ||

| + | |||

| + | <br><br> | ||

| + | |||

| + | ==Benderlink Videos== | ||

| + | |||

| + | <table> | ||

| + | <tr> | ||

| + | <td width=300> | ||

| + | *'''Introduction to Communicating with a Vector''' See [http://youtu.be/mldZ92XJ8_4 YouTube video] or [http://www.advancedtubular.com/blink_cncbender/cnc_procontrol_vector_communications.mp4 View an MP4 file]<br><br> | ||

| + | |||

| + | *'''Tutorial 1 for Eaton Leonard Vector''' - This [http://www.youtube.com/watch?v=esSXBZOZKuY YouTube video] demonstrates the Benderlink receiving a new part from a Vector Tube Data Center.<br><br> | ||

| + | |||

| + | *'''Tutorial 2 for Eaton Leonard Vector''' - This [http://www.youtube.com/watch?v=QwHkE3Sjeq4 YouTube video] demonstrates the Benderlink receiving corrections data from a Vector Tube Data Center. | ||

| + | |||

| + | </td> | ||

| + | |||

| + | <td> | ||

| + | [[image:cncv12_benderlinkvideo.jpg|500px]] | ||

| + | </td> | ||

| + | |||

| + | </tr> | ||

| + | </table> | ||

| + | |||

| + | == Software Updates == | ||

| + | |||

| + | <table> | ||

| + | <tr><td>October 7, 2013</td><td>[[Benderlink for CNC Bender v12.4]]</td></tr> | ||

| + | <tr><td>March 04, 2010</td><td>[[Benderlink for CNC Bender v12]]</td></tr> | ||

| + | <tr><td>March 19, 2008</td><td>[[Benderlink for CNC Bender v10.5]]</td></tr> | ||

| + | </table> | ||

| + | |||

| + | <table> | ||

| + | |||

| + | == Other Pages == | ||

| + | See [[Principles of CNC Bender Data Transfer]] | ||

Latest revision as of 01:54, 10 May 2017

Description

|

Benderlink is designed to make a connection between CNC Bender and measuring centers to allow measuring centers to steer the bender to the correct part shape quickly.

|

Features

|

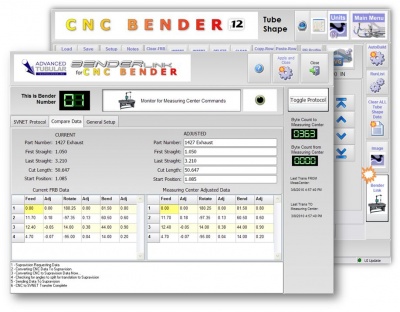

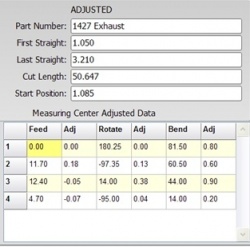

POWERFUL COMPARE and APPROVE |

Benderlink for CNC Bender ProControl v14 is one of the most powerful versions of Benderlink available in any CNC bender software package with the new COMPARE feature. |

|

|

BUILT-IN INDUSTRY STANDARD PROTOCOLS |

Protocols supported directly are: Our VTube-LASER (FARO), Supravision Network Protocol (ROMER) and Eaton Leonard Vector Tube Data Center |

|

|

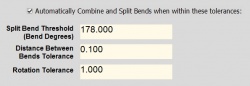

SMART BEND COMBINATION |

Benderlink automatically combines bends for the bender that should be combined. |

|

|

SMART SPLIT BEND |

Benderlink automatically splits bends for the measuring center that should be split. |

|

|

SMART NEW PART DETECTION |

Benderlink automatically detects when the part data is new versus when the part data is an existing setup that should be corrected. |

|

|

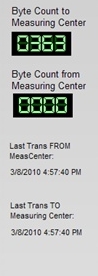

CLEAR ACTIVITY FEEDBACK |

With our Benderlink you can know for sure that data was transferred. You can even see when it was transferred - in either direction. Benderlink helps you know that communications are active by display LED counters with the exact byte count sent or received. The "Last Trans" labels let you see when the last transfer occurred. |

Benderlink Videos

|

Software Updates

| October 7, 2013 | Benderlink for CNC Bender v12.4 |

| March 04, 2010 | Benderlink for CNC Bender v12 |

| March 19, 2008 | Benderlink for CNC Bender v10.5 |