Setup CNC Bender to Switch Pressure to LOW Automatically

This describes basic principles for automatically setting the pressure to LOW in CNC Bender.

Contents |

Modify the CONSTANT RUN Processlist

|

The Constant Run Processlist is good for tasks that should run ever 3/4 of a second. The process is reserved for non-motion type commands. |

||

|

STEP 1 |

Find the section of the Constant Run that looks like this: |

[if] and, BeyondPowerOnTime=2000, BeyondLastCycleTime=5000, BeyondLastCycleTime=not(6000), output=Output_High_Pressure [display]AUTOMATIC HIGH to LOW PRESSURE After 5 Seconds LowPressureOn [end] |

|

STEP 2 |

Save the file to the c:\cnc\svparts folder in CNC Bender operator station (use a thumb drive or make a direct network connection) |

|

|

STEP 3 |

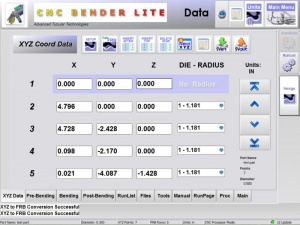

In CNC Bender, go to the Tube Shape menu/XYZ tab |

|

|

STEP 4 |

Press the SVin button button to select the Supravision file. Import the data into the XYZ page. |

|

|

STEP 5 |

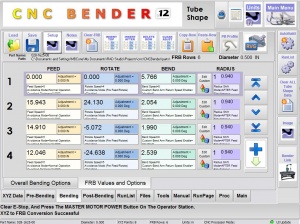

Press the Calc FRB button to build the bender data |

|

|

STEP 6 |

CNC Bender automatically switches to the FRB menu to display the calculated data |

IDEA 2: Enter the Data in CNC Bender Offline Then Save as a Part

|

The OFFLINE version of CNC Bender can be used to enter part data at a remote station, then save parts that are compatible with CNC Bender software. |

||

|

STEP 1 |

Enter data in the Tube Shape menu (Pre-Bend, FRB, Post-Bend). |

|

|

STEP 2 |

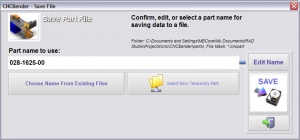

Press the SAVE button. |

|

|

STEP 3 |

Enter the Part name to use in the Save Part File menu and press Save.

|

|

|

STEP 4 |

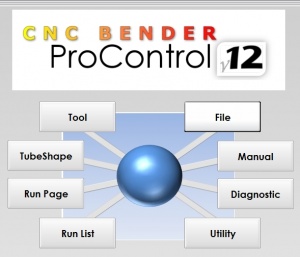

Enter the File menu by pressing the File button in the main menu. |

|

|

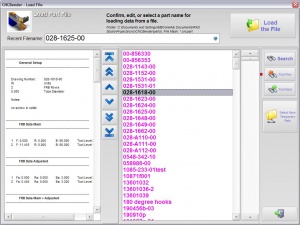

STEP 5 |

Press the Load Part button |

|

|

STEP 6 |

Select the new part just copied and press the Load the File button. |

|

|

STEP 7 |

Finalize the setup of the bender. |

IDEA 3: Send New Data or Corrections Data From a Measuring Center Through Benderlink

|

Benderlink for CNC Bender is designed primarily as a way to connect CNC Bender to a measuring center to allow the measuring center to control the bender setup. It is possible to connect to any SV-Network-compatible bender, or any Eaton-Leonard-Premier compatible bender with Benderlink. See more here: Benderlink for CNC Bender |

IDEA 4: Combine Ideas 1 and 2

|

You could use SVin in CNC Bender OFFLINE at a remote engineering station to use data from outside sources to setup the bender before the data reaches the operator station.

|

Other Pages

- See CNC Bender

- See CNC Bender Tutorials