Difference between revisions of "VTube-LASER Cylinder Fit Tolerances"

(→Default Tolerances) |

(→How to Test for and Use Cylinder Fit Tolerances for Your Application) |

||

| (6 intermediate revisions by one user not shown) | |||

| Line 82: | Line 82: | ||

</td> | </td> | ||

<td width=500> | <td width=500> | ||

| − | [[image:vtube- | + | [[image:vtube-laser_default_CylinderFitTolerances2.png|500px|right]] |

</td> | </td> | ||

</tr> | </tr> | ||

| Line 98: | Line 98: | ||

</td> | </td> | ||

<td width=500> | <td width=500> | ||

| − | [[image:vtube-laser_default_CylinderFitTolerances | + | [[image:vtube-laser_default_CylinderFitTolerances aerospace1.png|500px|right]] |

</td> | </td> | ||

</tr> | </tr> | ||

| Line 115: | Line 115: | ||

Test for ideal cylinder fit tolerance settings by measuring tubes and watching the tolerance values in the Cylinder Fit window.<br><br>You will learn that your material regularly measures with certain maximum fit deviations.<br><br> | Test for ideal cylinder fit tolerance settings by measuring tubes and watching the tolerance values in the Cylinder Fit window.<br><br>You will learn that your material regularly measures with certain maximum fit deviations.<br><br> | ||

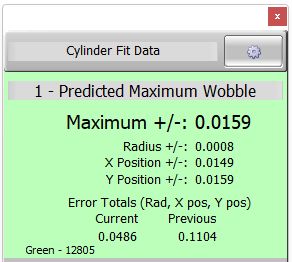

| − | As an example, if you never see deviations over 0. | + | As an example, if you never see deviations over 0.0159" (like shown on the right), you could set the tolerance value to 0.040" (which is just over double the max observed). If a cylinder fit deviation exceeds double the norm, then you can safely assume that there is a problem in the measurement, and you should be warned.<br><br> |

When watching for these values during measurements, keep in mind that you need to consider both the longer straight and shorter straight tolerances. Short straights will nearly always need higher tolerances. | When watching for these values during measurements, keep in mind that you need to consider both the longer straight and shorter straight tolerances. Short straights will nearly always need higher tolerances. | ||

| Line 121: | Line 121: | ||

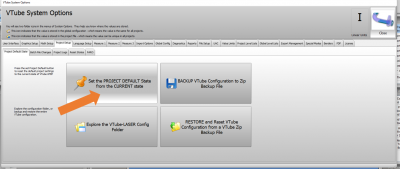

To change the default values, be sure to CLEAR the VTube-LASER project first, then press the "Set Project Default State to the current state" button. This will use the new default cylinder fit tolerances for all new projects.</td> | To change the default values, be sure to CLEAR the VTube-LASER project first, then press the "Set Project Default State to the current state" button. This will use the new default cylinder fit tolerances for all new projects.</td> | ||

<td width=500> | <td width=500> | ||

| − | [[image:Vtube- | + | [[image:Vtube-laser_cylinderfitwindow3.jpg|300px]]<br><br> |

[[image:vtube set default project state to the current state1.png|400px]] | [[image:vtube set default project state to the current state1.png|400px]] | ||

</td> | </td> | ||

Latest revision as of 13:55, 24 June 2022

|

How Does VTube-LASER Use Cylinder Fit Tolerances?

|

Contents |

Answer

|

VTube-LASER uses scanned surface points to calculate tube centerlines. |

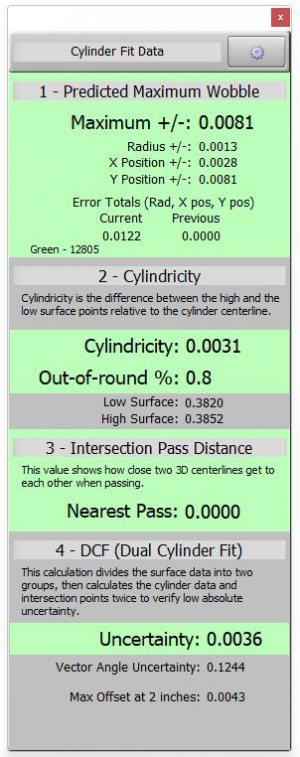

The Cylinder Fit Data Window Reports How Well the Centerline Fits the Surface Data

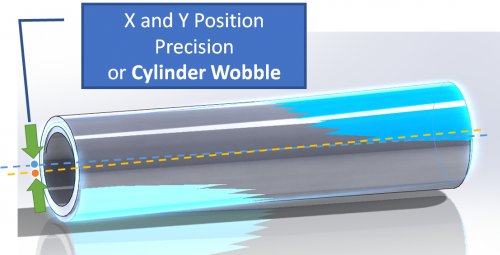

Cylinder Wobble - The highest of the X or Y values

|

To simplify visualizing the X and Y positions, we say that the highest of the X and Y values is the "cylinder wobble". The cylinder wobble in the example on the right is 1.3036 inches - because it is the higher of the two values. |

Controlling Cylinder Fit Tolerance Values

VTube-LASER uses tolerance values to decide when to warn you about potentially poor cylinder measurements.

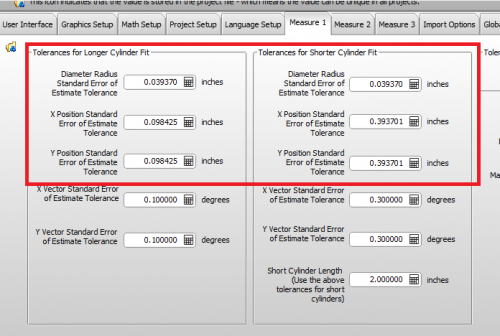

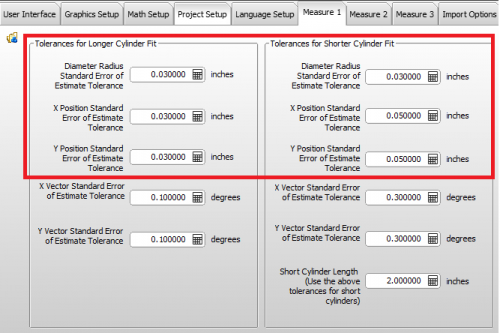

These values can be adjusted in the Measure 1 menu of System Options.

Default Tolerances

|

The default values are designed as a good starting point in the VTube-LASER setup. They are excellent for quick demonstrations of the software, and work great for tubes that have a lot of deformation in the straights. |

Aerospace Tolerances

|

Aerospace-grade materials are more precise compared to other applications. For aerospace applications, we recommend that you use tighter tolerances like the ones shown here. |

How to Test for and Use Cylinder Fit Tolerances for Your Application

|

You can adjust the tolerances in System Options to better fit your application and increase the assurance that your centerline is a good fit to the surface data. Test for ideal cylinder fit tolerance settings by measuring tubes and watching the tolerance values in the Cylinder Fit window. As an example, if you never see deviations over 0.0159" (like shown on the right), you could set the tolerance value to 0.040" (which is just over double the max observed). If a cylinder fit deviation exceeds double the norm, then you can safely assume that there is a problem in the measurement, and you should be warned. When watching for these values during measurements, keep in mind that you need to consider both the longer straight and shorter straight tolerances. Short straights will nearly always need higher tolerances. To change the default values, be sure to CLEAR the VTube-LASER project first, then press the "Set Project Default State to the current state" button. This will use the new default cylinder fit tolerances for all new projects. |

Why Are There Separate Values for Shorter Straights?

|

Math engines cannot calculate short straights as accurately as long straights. This has to do with the nature of cylinder math. It's a common issue with all measuring centers. Because of this, we know that VTube needs to be more patient with when fitting a cylinder centerline when the straight length is below a certain value. |

Other Pages

- Back to VTube-LASER

- See also Why VTube-LASER Reduces Data to Centerlines

- See also VTube-LASER Prioritizes Measuring Tube Straights