|

|

| (15 intermediate revisions by one user not shown) |

| Line 1: |

Line 1: |

| − | [[image:cnclaptop.jpg|right]]

| + | <table> |

| − | <br><br> | + | <tr> |

| − | =Steps to Change the Machine Length= | + | <td width=200> |

| | + | ==Changing the Machine Length== |

| | + | *Back to [[CNC Bender]] |

| | + | *Back to [[CNC Bender Tutorials]] |

| | + | *Back to [[CNC Bender Software Updates]] |

| | | | |

| − | ==Step 1== | + | </td> |

| | + | <td width=300> |

| | + | [[image:cncv12procontrol_withteachmode.jpg|300px]]<br> |

| | + | </td> |

| | + | <td> |

| | + | </td> |

| | + | </tr> |

| | + | </table> |

| | + | __NOTOC__ |

| | | | |

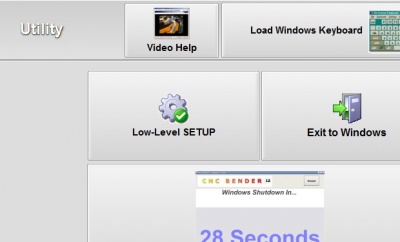

| − | Change to the Utility Menu, and press the Low-Level SETUP button.

| |

| − | <br><br>

| |

| − | [[image:cnc_low-level_setup_button.jpg|400px]]

| |

| − |

| |

| − |

| |

| − | ==Step 2==

| |

| − |

| |

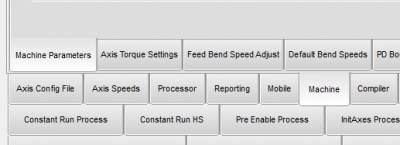

| − | Change to the Machine Tab, then the Machine Parameters tab sub menu.

| |

| − | <br><br>

| |

| − | [[image:cnc_machineparameters_tab.jpg|400px]]

| |

| − |

| |

| − |

| |

| − | ==Step 3==

| |

| − |

| |

| − | Edit the machine length by touching and changing the machine length edit box.

| |

| − | <br><br>

| |

| − | [[image:cnc_machinelength_edit.jpg|400px]]

| |

| − |

| |

| − |

| |

| − |

| |

| − | =HOW TO CHANGE THE MACHINE LENGTH=

| |

| | | | |

| | Follow these steps to change the Machine Length. | | Follow these steps to change the Machine Length. |

| Line 47: |

Line 38: |

| | <font size=4><b>STEP 2</b></font> | | <font size=4><b>STEP 2</b></font> |

| | ----<br> | | ----<br> |

| − | USB Flash Drive

| + | Change to the Machine Tab, then the Machine Parameters tab sub menu. |

| | </td> | | </td> |

| | <td bgcolor="#e3e4f5"> | | <td bgcolor="#e3e4f5"> |

| − | Plug a USB FLASH DRIVE[http://en.wikipedia.org/wiki/USB_flash_drive] into the operator station USB port (inside the enclosure). (You will need a FLASH DRIVE with about 100 Megabytes of free memory.)[[image:flashdrive.jpg|thumb|USB Flash Drive]]

| + | [[image:cnc_machineparameters_tab.jpg|400px]] |

| | </td> | | </td> |

| | </tr> | | </tr> |

| Line 58: |

Line 49: |

| | <font size=4><b>STEP 3</b></font> | | <font size=4><b>STEP 3</b></font> |

| | ----<br> | | ----<br> |

| − | Find CNC Folder

| + | Edit the machine length by touching and changing the machine length edit box. |

| | </td> | | </td> |

| | <td bgcolor="#e3e4f5"> | | <td bgcolor="#e3e4f5"> |

| − | Browse to the C:\CNC folder on the operator station using Windows Explorer.

| + | [[image:cnc_machinelength_edit.jpg|400px]] |

| | </td> | | </td> |

| | </tr> | | </tr> |

| Line 69: |

Line 60: |

| | <font size=4><b>STEP 4</b></font> | | <font size=4><b>STEP 4</b></font> |

| | ----<br> | | ----<br> |

| − | Copy CNC Folder

| + | Press the Main Menu button. |

| | </td> | | </td> |

| | <td bgcolor="#e3e4f5"> | | <td bgcolor="#e3e4f5"> |

| − | Copy the CNC FOLDER to the USB flash drive.

| + | [[image:cnc_low-level_mainmenu_button.jpg|400px]] |

| | </td> | | </td> |

| | </tr> | | </tr> |

| | | | |

| − | <tr valign="top">

| |

| − | <td bgcolor="#abbad1" width = 200>

| |

| − | <font size=4><b>STEP 5</b></font>

| |

| − | ----<br>

| |

| − | Remove the USB Flash Drive

| |

| − | </td>

| |

| − | <td bgcolor="#e3e4f5">

| |

| − | Remove the USB flash drive using the system tool tray "Safely Remove Hardware" feature.

| |

| − | </td>

| |

| − | </tr>

| |

| − |

| |

| − | <tr valign="top">

| |

| − | <td bgcolor="#abbad1" width = 200>

| |

| − | <font size=4><b>STEP 6</b></font>

| |

| − | ----<br>

| |

| − | Plug the USB Flash Drive In

| |

| − | </td>

| |

| − | <td bgcolor="#e3e4f5">

| |

| − | Plug the USB flash drive into the NEW target computer.

| |

| − | </td>

| |

| − | </tr>

| |

| − |

| |

| − | <tr valign="top">

| |

| − | <td bgcolor="#abbad1" width = 200>

| |

| − | <font size=4><b>STEP 7</b></font>

| |

| − | ----<br>

| |

| − | Copy to C:\CNC

| |

| − | </td>

| |

| − | <td bgcolor="#e3e4f5">

| |

| − | Use Windows Explorer to copy the data to the same folder on the target computer's drive. The folder should be "c:\cnc"

| |

| − | </td>

| |

| − | </tr>

| |

| − |

| |

| − | <tr valign="top">

| |

| − | <td bgcolor="#abbad1" width = 200>

| |

| − | <font size=4><b>STEP 8</b></font>

| |

| − | ----<br>

| |

| − | Run the Hardware Key DRIVER

| |

| − | </td>

| |

| − | <td bgcolor="#e3e4f5">

| |

| − | [[image:haspdriver.jpg|thumb|HASP Driver Software]]

| |

| − | Browse to the c:\cnc\key folder and run "hdd32.exe." This program is a hardware key driver file that needs only to be run once. It may require that you be logged in as a user with administrative rights.

| |

| − |

| |

| − | Download the latest hdd32.exe file here: http://www.advancedtubular.com/key/hdd32.exe

| |

| − | </td>

| |

| − | </tr>

| |

| − |

| |

| − | <tr valign="top">

| |

| − | <td bgcolor="#abbad1" width = 200>

| |

| − | <font size=4><b>STEP 9</b></font>

| |

| − | ----<br>

| |

| − | Transfer Hardware Key

| |

| − | </td>

| |

| − | <td bgcolor="#e3e4f5">

| |

| − | [[image:hasp.jpg|thumb|Hasp Hardware Key]]

| |

| − | Remove the hardware key from the USB port of the CNC Bender operator station (inside the operator station enclosure).

| |

| − |

| |

| − | Plug it into the new computer's USB port.

| |

| − | </td>

| |

| − | </tr>

| |

| − |

| |

| − |

| |

| − | <tr valign="top">

| |

| − | <td bgcolor="#abbad1" width = 200>

| |

| − | <font size=4><b>STEP 10</b></font>

| |

| − | ----<br>

| |

| − | Set the NEW Computer IP Address

| |

| − | </td>

| |

| − | <td bgcolor="#e3e4f5">

| |

| − | Use the Windows Start / Connect To menu to configure the TCP/IP address of the port that will connect to the bender. Set that port to a fixed IP address of 192.168.0.199. Any valid setting under 200 for the last [[octet]] will work. The operator station uses .200 as the address. If the operator station is not powered on, or is not attached to the bender network, then you can also use address .200.

| |

| − | </td>

| |

| − | </tr>

| |

| − |

| |

| − |

| |

| − | <tr valign="top">

| |

| − | <td bgcolor="#abbad1" width = 200>

| |

| − | <font size=4><b>STEP 11</b></font>

| |

| − | ----<br>

| |

| − | Plug Ethernet

| |

| − | </td>

| |

| − | <td bgcolor="#e3e4f5">

| |

| − | Plug an ethernet cable (RJ45 type) between the new computer's NIC port and the Netgear switch in the electronics cabinet using a standard ethernet cable. [[image:netgearswitch.jpg|thumb|Netgear Switch]]

| |

| − | </td>

| |

| − | </tr>

| |

| − |

| |

| − | <tr valign="top">

| |

| − | <td bgcolor="#abbad1" width = 200>

| |

| − | <font size=4><b>STEP 12</b></font>

| |

| − | ----<br>

| |

| − | CNC Bender Software

| |

| − | </td>

| |

| − | <td bgcolor="#e3e4f5">

| |

| − | Start CNC Bender software by finding the CNCBender.exe program in the c:\cnc folder and double clicking on it (or select the file and press Enter).

| |

| − | [[image:cncbender.jpg|thumb|CNC Bender Software]]

| |

| − | </td>

| |

| − | </tr>

| |

| | | | |

| | </table> | | </table> |

| − |

| |

| − |

| |

| − | From this point, operation of CNC Bender is identical to the operation of CNC Bender on the operating station. The physical buttons on the operator station are still needed to operate the bender. The replacement computer should probably be placed near the operator station.

| |

| − |

| |

| − | Note: Since the operator station is completely powered down, the touchscreen is no longer used while using the backup computer. Use the mouse on the new computer to simulate the touchscreen.

| |

| | | | |

| | | | |

| | <br><br> | | <br><br> |

| | | | |

| − | =SOUND SYSTEM= | + | =Other= |

| − | Auditory sound messages are an important part of knowing the state of the bender control. I recommend that you be sure to use a computer with a sound system for operating CNC Bender sofware.

| + | *Back to [[CNC Bender]] |

| − | | + | |

| − | --[[User:Mcone|Mcone]] 13:07, 5 March 2007 (EST)

| + | |

Follow these steps to change the Machine Length.