Difference between revisions of "End-Scan Using the Scissor Motion"

From ATTWiki

(→Why the End-Scan technique is important) |

(→Apply the Target) |

||

| Line 30: | Line 30: | ||

</table> | </table> | ||

| − | === | + | ===Align the Scanner=== |

<table cellpadding=10> | <table cellpadding=10> | ||

<tr valign=top> | <tr valign=top> | ||

<td width=300> | <td width=300> | ||

| − | * | + | * Align the scanner with a slight scissor angle across the end as is shown in the image on the right<br><br> |

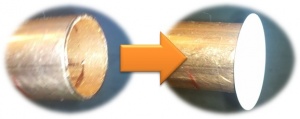

*The solution is to use white targets on the end of the tubes. The example here shows white poly labels that measure at 0.004" thick and provide an excellent flat target for the laser.<br><br>(Note: Use the Plane-Point measurement in the built-in computer of the FARO Edge to confirm the thickness of the target.)<br><br> | *The solution is to use white targets on the end of the tubes. The example here shows white poly labels that measure at 0.004" thick and provide an excellent flat target for the laser.<br><br>(Note: Use the Plane-Point measurement in the built-in computer of the FARO Edge to confirm the thickness of the target.)<br><br> | ||

* The offset from the target to the tube end is entered as a negative value in the Part Setup menu for either end. In this case, we use -0.004" offset.<br><br> | * The offset from the target to the tube end is entered as a negative value in the Part Setup menu for either end. In this case, we use -0.004" offset.<br><br> | ||

Revision as of 22:32, 27 January 2012

|

|

Why the End-Scan technique is important

|

This end-scan method is useful for ease-of-use and quickness.

|

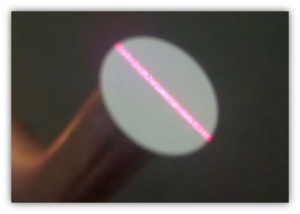

Align the Scanner

|

Measure the Target

|

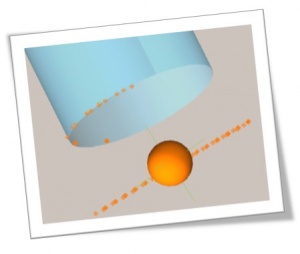

When it is time to perform and end-scan, use the following technique to scan the target:

|

Approve the Measurement On the Screen

|

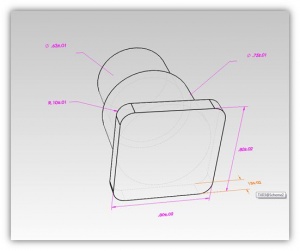

Using End Target Adapters

|

|

- Back to VTube-LASER