Difference between revisions of "CNC Bender v12-20100903"

| (18 intermediate revisions by one user not shown) | |||

| Line 257: | Line 257: | ||

| − | ===[[image:Check.jpg|25px]] FIXED- Linear System Values | + | ===[[image:Check.jpg|25px]] FIXED- Linear System Values Correct Units === |

<table> | <table> | ||

<tr valign=top> | <tr valign=top> | ||

| Line 263: | Line 263: | ||

The linear system values in the numeric keypad now display values in correct units (inches or millimeter)</td> | The linear system values in the numeric keypad now display values in correct units (inches or millimeter)</td> | ||

<td> | <td> | ||

| + | [[image:cncbender_numberickeypad_systemvalues.jpg|350px]] | ||

</td> | </td> | ||

</tr> | </tr> | ||

| Line 276: | Line 277: | ||

<br><br> | <br><br> | ||

| + | |||

| + | |||

| + | |||

| + | ===[[image:Check.jpg|25px]] ENHANCED - FEED POSITION SYNCHRONIZATION === | ||

| + | <table> | ||

| + | <tr valign=top> | ||

| + | <td width=200> | ||

| + | The Feed positions from front and back are now synchronized with each other based on machine length.</td> | ||

| + | <td> | ||

| + | [[image:cncbender_feedpositions_synchronized.jpg|350px]] | ||

| + | </td> | ||

| + | </tr> | ||

| + | </table> | ||

| + | |||

| + | ===[[image:Check.jpg|25px]] ENHANCED - NUMERIC KEYPAD - JOYSTICK === | ||

| + | <table> | ||

| + | <tr valign=top> | ||

| + | <td width=200> | ||

| + | A joystick image replaces the gear symbol to make the function of the button more clear. | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:cncbender_joystick_in_numerickeypad.jpg|350px]] | ||

| + | </td> | ||

| + | </tr> | ||

| + | </table> | ||

| + | |||

| + | ===[[image:Check.jpg|25px]] ENHANCED - JOG WINDOW - JOYSTICK CAPABLE === | ||

| + | |||

| + | <table> | ||

| + | <tr valign=top> | ||

| + | <td width=200> | ||

| + | The JOG WINDOW now responds to joystick input. | ||

| + | <br><br> | ||

| + | Select the axis then jog with a joystick. | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:cncbender_jogwindow.jpg|350px]] | ||

| + | </td> | ||

| + | </tr> | ||

| + | </table> | ||

| + | |||

| + | ===[[image:Check.jpg|25px]] ENHANCED - HIGH PRESSURE - START in MIDDLE === | ||

| + | <table> | ||

| + | <tr valign=top> | ||

| + | <td width=200> | ||

| + | CNC Bender can start a program anywhere in the middle of a bend program. To make this work properly on benders that require high pressure mode, CNC Processor automatically switches the bender to high pressure mode whenever AUTO mode is started. | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:cncbender_cyclestartindex.jpg|350px]] | ||

| + | </td> | ||

| + | </tr> | ||

| + | </table> | ||

| + | |||

| + | |||

| + | |||

| + | ===[[image:Check.jpg|25px]] FIX - Load External Programs - Keyboard, CIO, COMDEF === | ||

| + | <table> | ||

| + | <tr valign=top> | ||

| + | <td width=200> | ||

| + | CNC Bender had lost the ability to load the keyboard, CIO Dictionary, and COMDEF dictionary. This was repaired on 9/7/2010 in this release. (Post release repair)</td> | ||

| + | <td> | ||

| + | </td> | ||

| + | </tr> | ||

| + | </table> | ||

=Other Pages= | =Other Pages= | ||

Latest revision as of 17:26, 7 September 2010

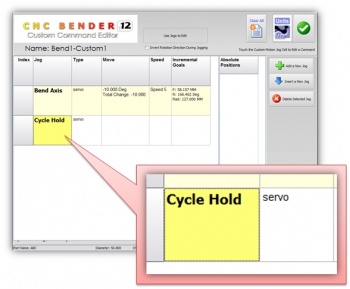

NEW - CYCLE HOLD in Custom Commands and in TEACH Mode

NEW - CYCLE HOLD in Custom Commands and in TEACH Mode

|

Now CYCLE HOLD anywhere inside a CUSTOM COMMAND either manually entered or taught during TEACH MODE. |

|

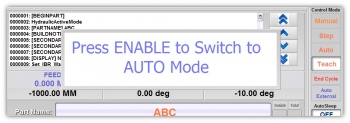

ENHANCED - ENABLE Button for STEP and AUTO Modes

ENHANCED - ENABLE Button for STEP and AUTO Modes

|

The "REQUIRE ENABLE BUTTON" feature, when active, now also monitors for a switch to AUTO or STEP modes from MANUAL mode |

|

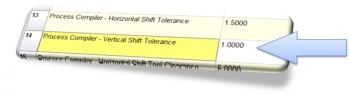

ENHANCED - Vertical Head Shift Tolerance Added

ENHANCED - Vertical Head Shift Tolerance Added

|

The vertical head shift tolerance allows us to skip motion when an axis is close enough to the final position. |

|

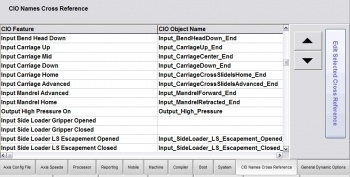

ENHANCED - Added CNC Processor Automatic High Pressure Handling

ENHANCED - Added CNC Processor Automatic High Pressure Handling

|

CNC Processor now uses the CIO Name Cross Reference in the Low Level menu to automatically set the high pressure under these two special circumstances:

|

|

ENHANCED - CNC Processor Soft EOT with New Ramp-Down for JOG Speeds

ENHANCED - CNC Processor Soft EOT with New Ramp-Down for JOG Speeds

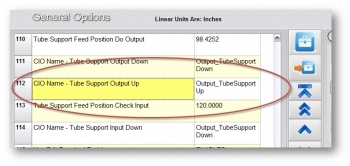

ENHANCED - EMBEDDED TUBE SUPPORT in CNC PROCESSOR

ENHANCED - EMBEDDED TUBE SUPPORT in CNC PROCESSOR

|

This feature allows CNC Bender's PROCESSOR to control when the tube support is lifted or dropped - and if the drop should be confirmed with an input. This revision adds the CIO Name of Tube Support Output UP in addition to the Down CIO name.

|

|

|

This revision also adds new logic was added to the tube support to push the support DOWN when homing is in process. This is to overcome the potential for the support driving up into the spindle because the Feed axis does not know where zero is until home is complete. |

ENHANCED - Simplified CNC BENDER Loader

ENHANCED - Simplified CNC BENDER Loader

|

The CNC Bender Loader is used to start CNC Bender in the operator station with a press. |

|

NEW- PDA At Home Tolerance

NEW- PDA At Home Tolerance

|

A new programmable tolerance for checking for PDA at HOME has been added to the Low Level dynamic options. |

|

ENHANCED- Pressure Die and Clamp Die Open With PDA Extended

ENHANCED- Pressure Die and Clamp Die Open With PDA Extended

| The Pressure Die and Clamp Dies will now open even if the PDA is extended. This restriction has been removed. | |

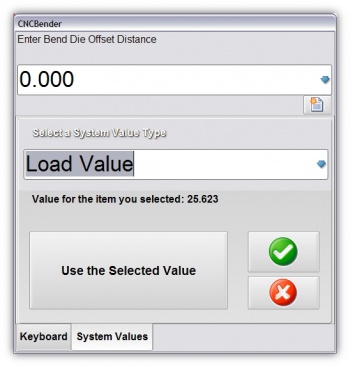

FIXED- Linear System Values Correct Units

FIXED- Linear System Values Correct Units

| The linear system values in the numeric keypad now display values in correct units (inches or millimeter) | |

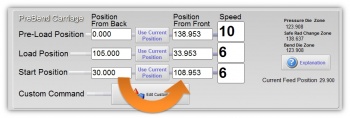

ENHANCED - FEED POSITION SYNCHRONIZATION

ENHANCED - FEED POSITION SYNCHRONIZATION

| The Feed positions from front and back are now synchronized with each other based on machine length. |

ENHANCED - NUMERIC KEYPAD - JOYSTICK

ENHANCED - NUMERIC KEYPAD - JOYSTICK

|

A joystick image replaces the gear symbol to make the function of the button more clear. |

ENHANCED - JOG WINDOW - JOYSTICK CAPABLE

ENHANCED - JOG WINDOW - JOYSTICK CAPABLE

|

The JOG WINDOW now responds to joystick input.

|

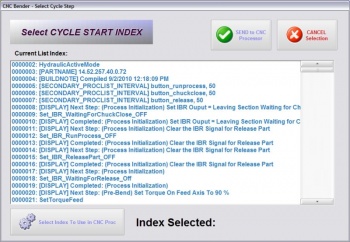

ENHANCED - HIGH PRESSURE - START in MIDDLE

ENHANCED - HIGH PRESSURE - START in MIDDLE

|

CNC Bender can start a program anywhere in the middle of a bend program. To make this work properly on benders that require high pressure mode, CNC Processor automatically switches the bender to high pressure mode whenever AUTO mode is started. |

FIX - Load External Programs - Keyboard, CIO, COMDEF

FIX - Load External Programs - Keyboard, CIO, COMDEF

| CNC Bender had lost the ability to load the keyboard, CIO Dictionary, and COMDEF dictionary. This was repaired on 9/7/2010 in this release. (Post release repair) |

Other Pages

- Back to CNC Bender

- Back to CNC Bender Software Updates

- See CNC Bender General Information

- See Teach Mode

- See Custom Commands