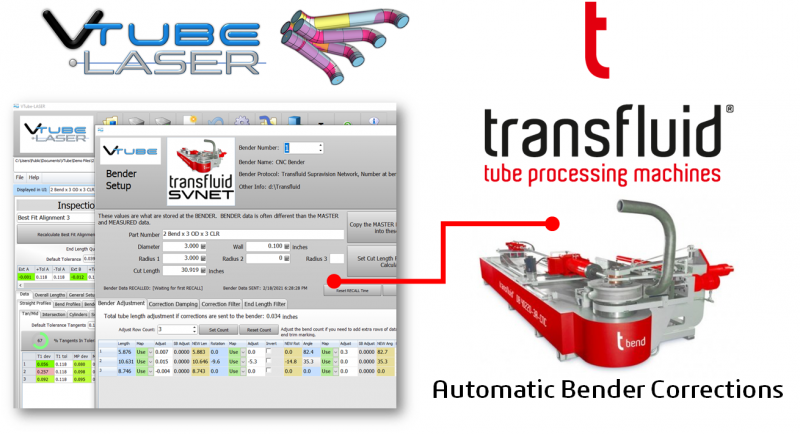

VTube Communications With Transfluid Benders

|

As of version 3.0 build 456 (March 29, 2021), we've embedded the Transfluid SVNET protocol in VTube-STEP and VTube-LASER. |

Video

Video 20210330: VTube-LASER to Transfluid Bender Communications

|

This video shows how easy it is to communicate with Transfluid tProject bender software. |

Configuring VTube-STEP and VTube-LASER for Communications with Transfluid tProject

You can perform this setup from VTube-STEP or VTube-LASER. The steps are identical in both.

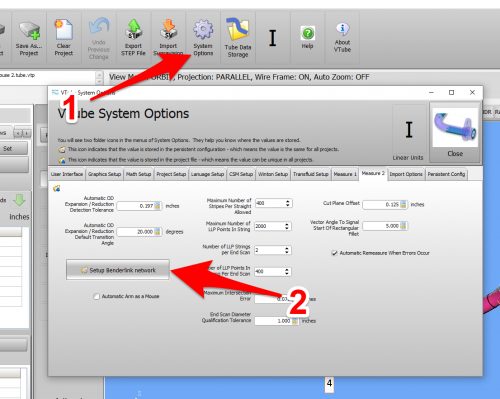

STEP 1: Enter the SYSTEM OPTIONS Menu in VTube

|

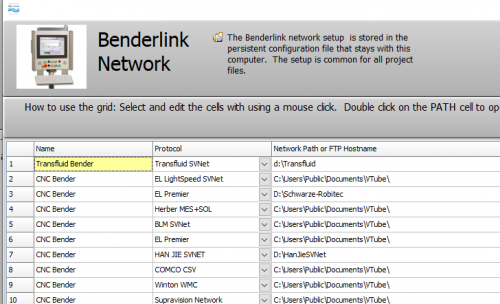

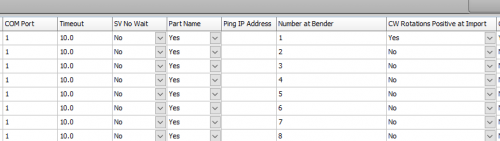

STEP 2: Setup the Benderlink Network Grid for Transfluid Supravision Network Protocol

|

Configuring Transfluid tProject for Communications with VTube-LASER and VTube-STEP

|

|

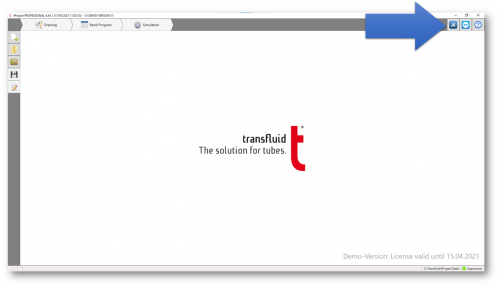

STEP 1: Enter Options Window

|

Click on the blue button wrench/screwdriver button in the upper right corner of the user interface. |

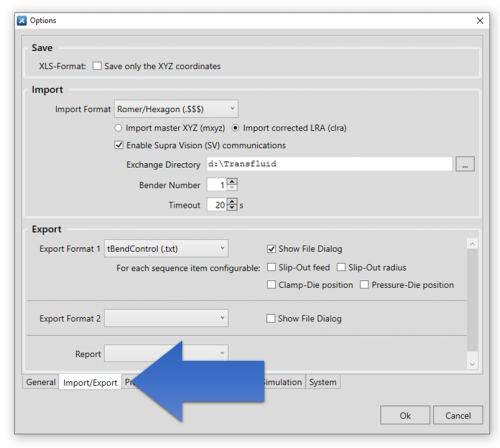

STEP 2: Enter the Import/Export Tab

|

Click on the Import/Export tab. |

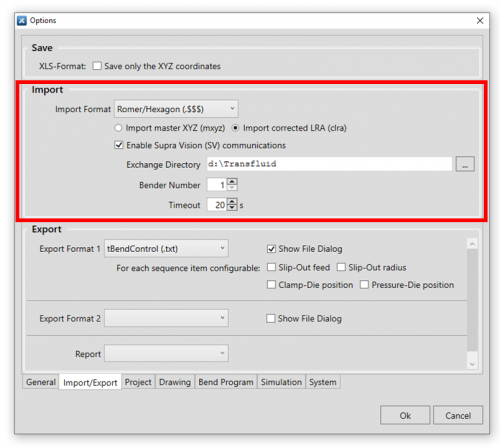

STEP 3: Set the Import Box Settings

|

Enter the set up data in the Import box.

|

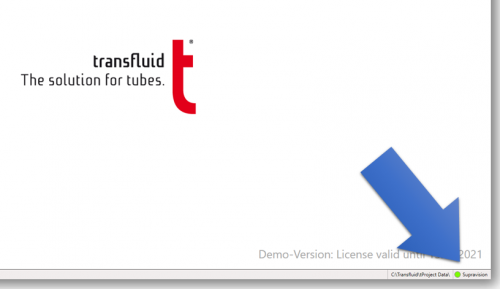

STEP 4: Check for a Green LED in the Main User Interface

|

Close the options menu with the OK button and check for the Supravision communications LED in the lower right corner of tProject. The LED should be green. |

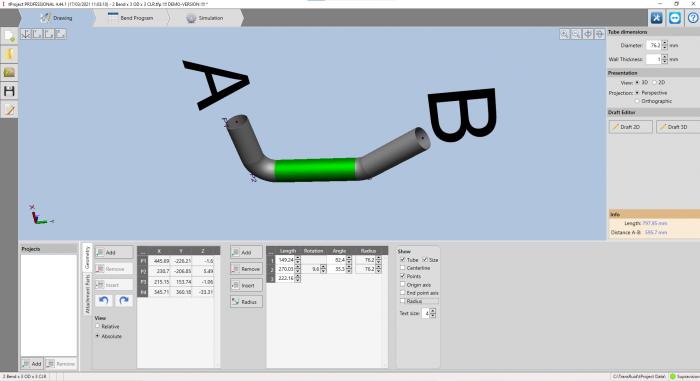

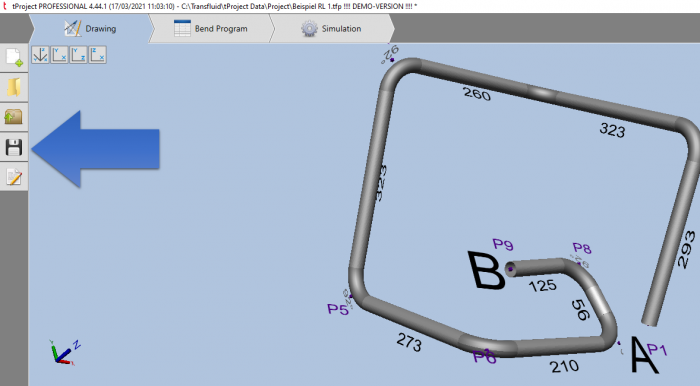

How to Prepare tProject to Receive New Data from VTube

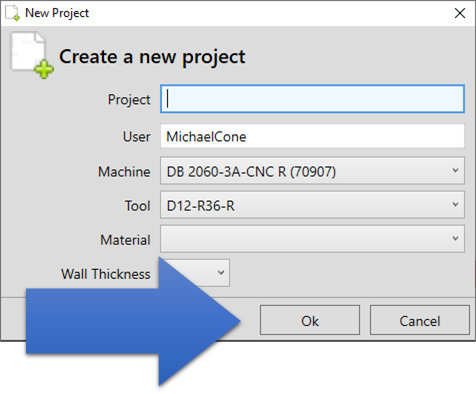

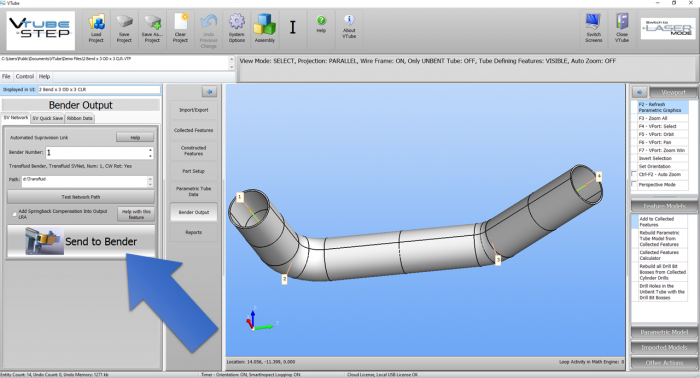

How to Send New Data to tProject from VTube-STEP

|

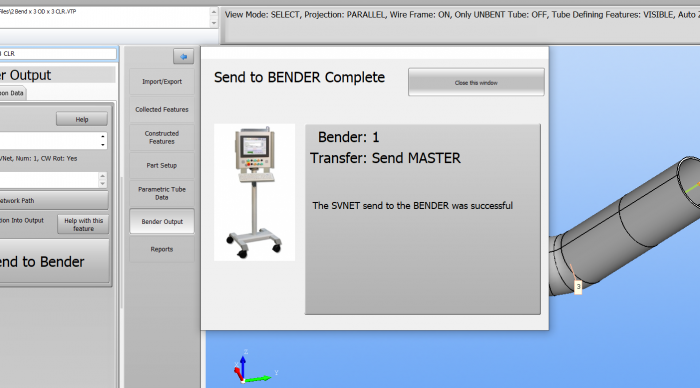

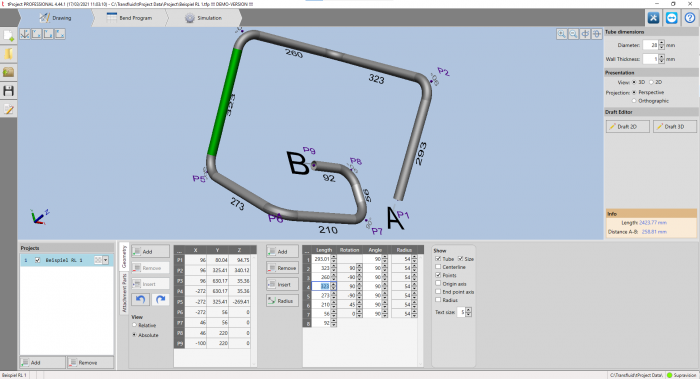

The Transfuild tProject program can receive data for a part that has never been sent to it before from VTube-STEP. This allows a user to import a solid model of any tube, then send it to tProject. STEP 1: Import the ModelImport the part using standard VTube-STEP procedures STEP 2: Bender Output MenuClick on the Bender Output button in the navigation pane. STEP 3: Bender NumberSelect the bender number for the Transfluid bender. STEP 4: SendClick Send to Bender. VTube will show "Send to Bender Complete" if it was able to save the output data for Transfluid. |

How to Prepare tProject for Bender Corrections from VTube-LASER

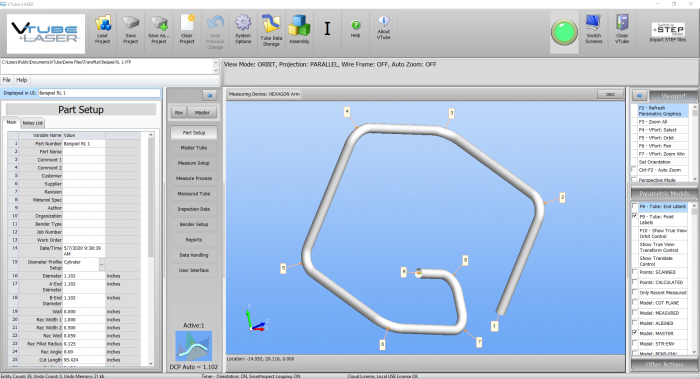

How to Set Up the VTube-LASER Project for Bender Corrections to tProject

|

The project must have a Part Number that is identical to the project file name in tProject. |

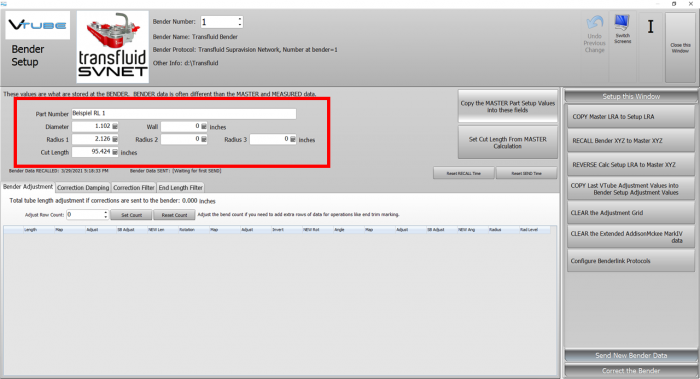

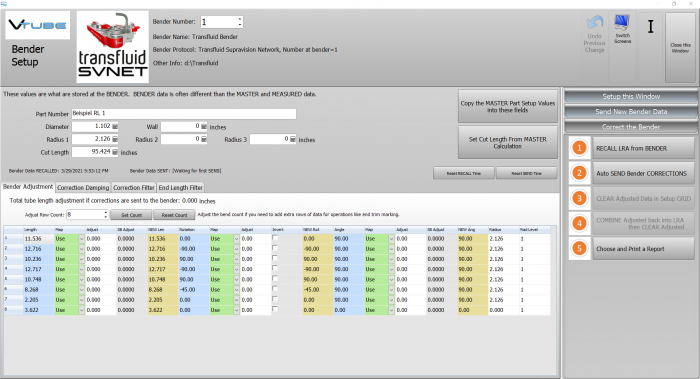

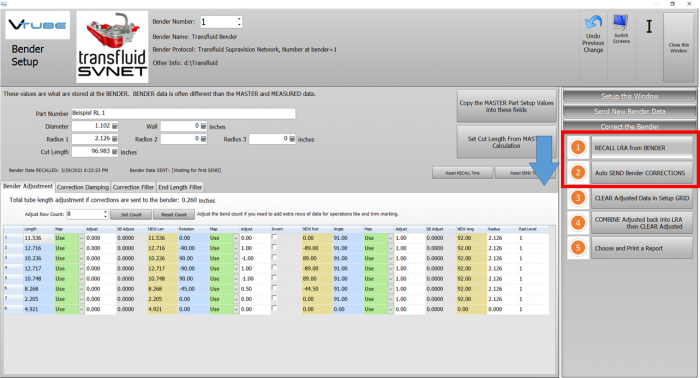

STEP 2: Enter the Bender Setup Menu

|

This menu allows you to communicate with any bender in the VTube-LASER network.

|

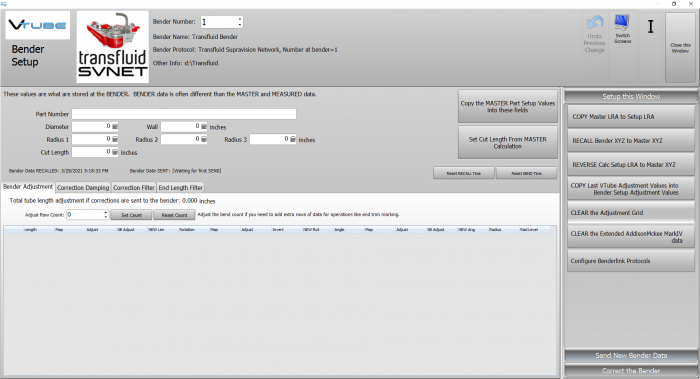

STEP 3: Bring Data Into This Window

|

If there is now data in the window like shown in the previous image, then click on "Copy the Master Part Setup Values into these fields" button.

|

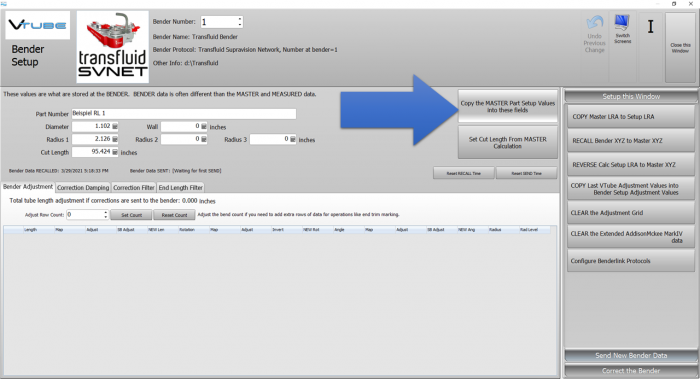

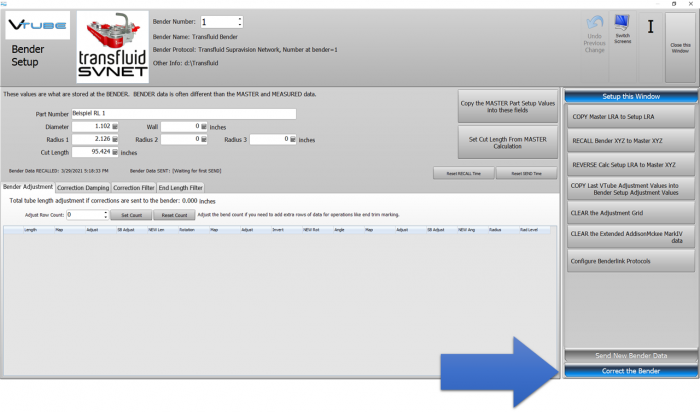

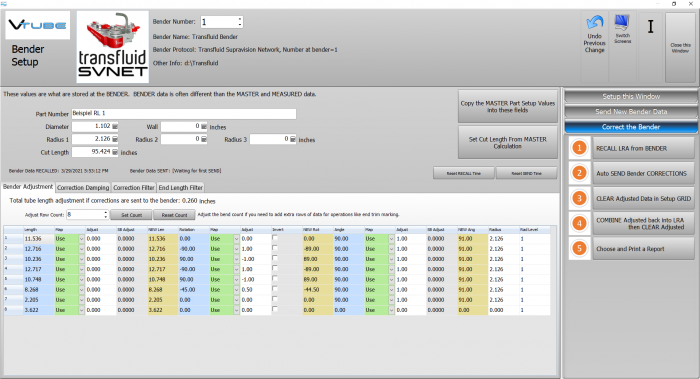

STEP 4: Click on Correct the Bender

|

Find and click on the "Correct the Bender" button in the lower right corner.

|

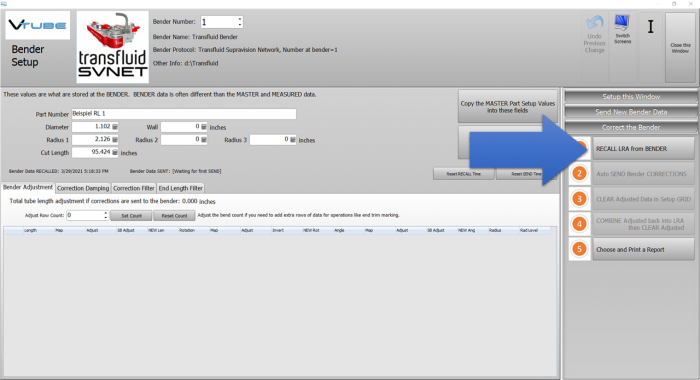

STEP 5: RECALL Bender Data

|

Press the RECALL LRA from BENDER button.

|

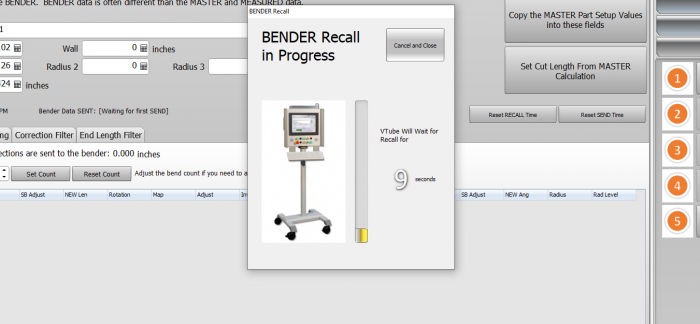

|

|

The RECALL window with a timer will display. Allow tProject to answer VTube-LASER.

|

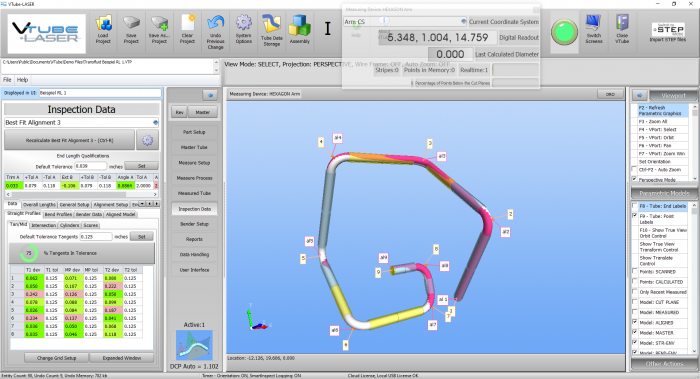

STEP 6: Allow VTube-LASER to Configure

|

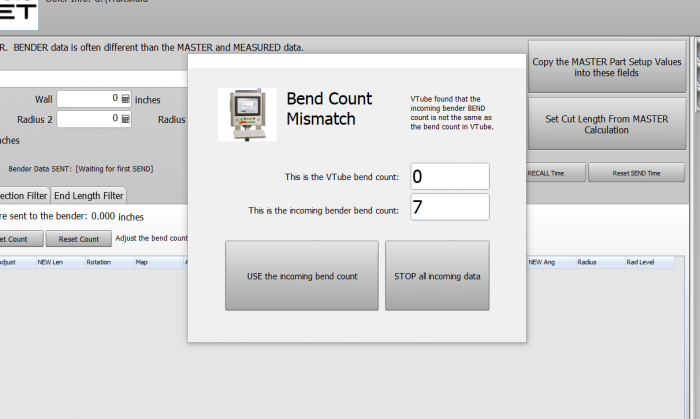

If the incoming bend count does not match what is currently in VTube-LASER, then VTube-LASER will ask you for some decisions like this one. Just Press "USE..." to let the incoming data takeover the page.

|

STEP 7: Bender Setup is Complete

|

The Bender Setup window is completely ready. This setup will be stored with the project from this point on. Press "Close this Window", bend, measure, and align the tube in VTube-LASER, then come back into this Bender Setup menu if the part is not within tolerance.

|

How to Send Corrections tProject Data with VTube-LASER Bender Setup

|

During measurement, VTube-LASER will automatically create correction data that will be transferred to Bender Setup. |

STEP 2: Enter the Bender Setup Menu

|

The white columns will show Adjustments that can be applied to the bender. |

STEP 3: RECALL then SEND

|

To be sure that the Blue columns have the latest data as was programmed by the bender operator at the Transfluid, press the RECALL LRA from BENDER button. |

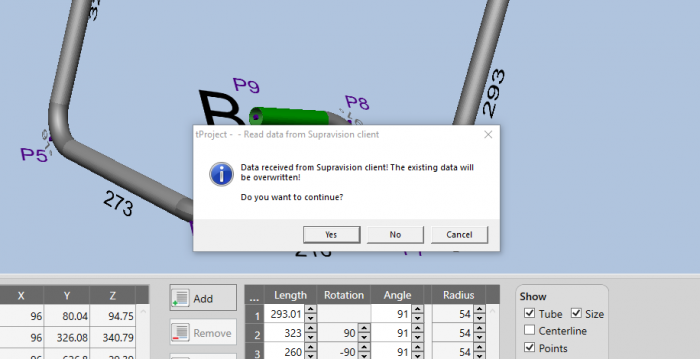

STEP 4: tProject Will Receive Data and Ask for Confirmation

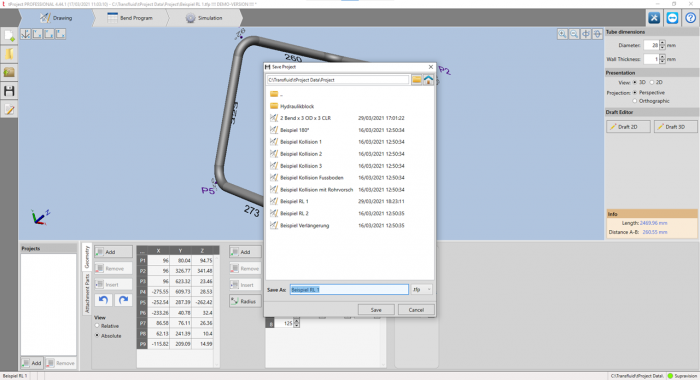

STEP 5: SAVE the tProject Project File

Rules for tProject Communication

Here are helpful rules for tProject communication.

Rule 1 - tProject Automatically Converts Linear Units

|

tProject will always automatically convert the incoming data to the linear unit that is being displayed on the screen. |

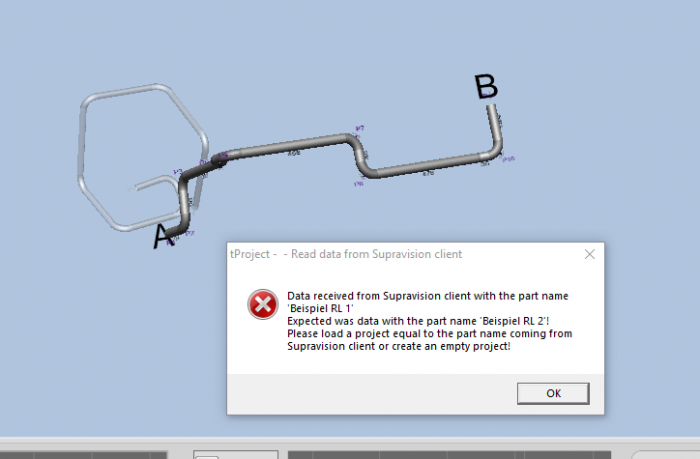

Rule 2 - tProject Will Block the Wrong Part

|

Unless the project is cleared without a part name, tProject will always block any data it receives that has the wrong VTube-LASER part number. |

Rule 3 - tProject Answers Recalls with the Data in tProject Files

|

tProject always answers VTube-LASER RECALLS with the project data in the disk file - NOT the project data on the screen. |

Rule 4 - tProject Does Not Answer A VTube-LASER Recall When the Part Does Not Exist

|

If tProject does not answer a VTube-LASER RECALL when everything else is working, then that tProject project does not exist. In that case, the process will time-out. |

Rule 5 - Manually Save tProject Project Files After Receiving Data from VTube-LASER

|

It is important to manually save the data that was just received by tProject from VTube-LASER. tProject will not save it automatically. |

Other Pages

- See VTube-LASER

- See VTube-STEP