About this Page

|

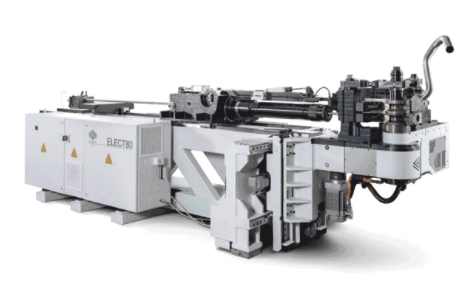

This page describes the setup and use of the VTube to BLM communications.

|

|

TWO PROTCOLS

|

As of early 2019, VTube-LASER supports one of two protocols for connecting to the BLM VGP3D control.

BLM CMM (NEWER) - RECOMMENDED

- The BLM CMM protocol was introduced in VTube-LASER version 2.9.18.

- It is the preferred protocol because it is very easy to use and does not interfer with custom commands inside the BLM VGP3D control.

- BLM may charge for this protocol to be switched on.

- The BLM catalog number is "SW0842".

- This protocol can send centerline UVW, bender XcYcZc, part number, diameter, wall thickness, cut length, and radii values.

BLM DATA (LEGACY)

- The older legacy control is referred to as BLM DATA. Older versions of VTube-LASER have this protocol.

- It can read and write native .BLM files for setup and correction.

- This is the protocol that you can use on older controls that do not have the BLM CMM control.

- This protocol does not send radii. (Sending radii data causes VGP3D to reset the tool page information.)

- The steps to use this protocol are more complicated than the BLM CMM protocol.

|

|

Communications Setup at the BLM Bender for Both Protocols

This network setup is similar for both protocols.

- Connect the BLM bender to the network.

- Connect the VTube-LASER computer to the network.

- Setup a shared network location either in the BLM windows control or in a network path on your network.

- If you share a folder on the BLM control, then create a user with a username and password that can be used to login to the computer from the VTube-LASER computer.

- If you are using the BLM CMM protocol, then on the VGP3D you must map to the shared network drive. The drive letter for the map must be Z:\. (This is a fixed letter inside VGP3D logic.)

|

|

NEWER BLM CMM Protocol Section

NEWER BLM CMM PROTOCOL: The Capabilities

- VTube-LASER RECALLS, MODIFIES, and SAVES data directly in "CMM.txt" files that the VGP3D software can export and import. Per the instructions above, a communications link can be setup through a standard Windows network connection.

- The communication is bi-directional to and from the bender. It is possible to RECALL data from the BLM using the CMM.txt file format.

- The data that is included in the BLM CMM.txt file that the BLM can read/write is the UVW data (the tube centerline data), the BENDER data (Xc axis, Yc Axis, Zc Axis). The data also includes the diameter, wall, cut length, and all radii.

|

|

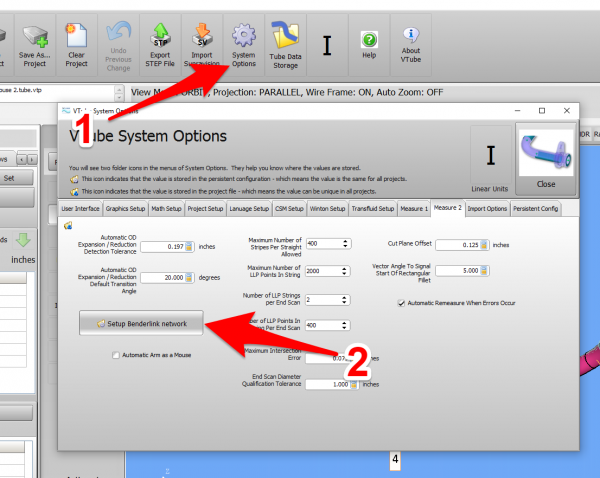

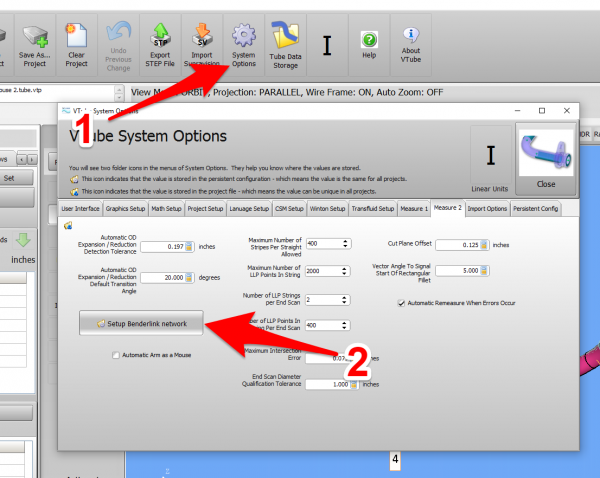

NEWER BLM CMM PROTOCOL: Setup Benderlink at VTube-STEP or VTube-LASER with the BLM CMM Protocol

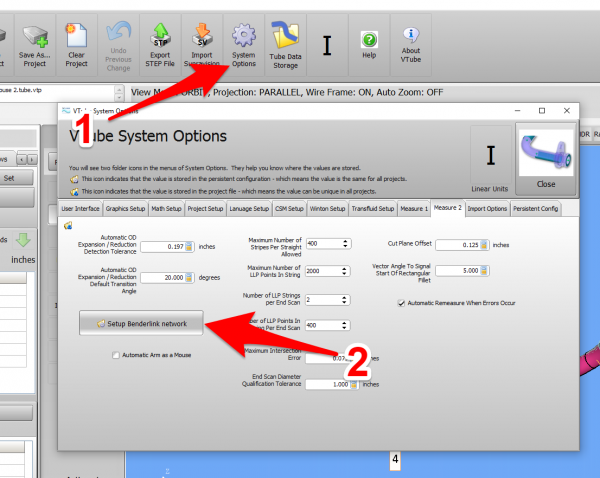

Entering Benderlink Setup

- Enter the VTube System Options menu.

- Enter the Measure 2 tab menu.

- Enter the Setup Benderlink Network menu.

|

|

NEWER BLM CMM PROTOCOL: Setup the Benderlink Network Grid for the BLM CMM Protocol

- Choose an unused row in the grid for a new BLM bender setup. (Click on the image at the right to see a zoomed image.)

- Assign a bender name that will help operators identify what this bender is. This text will be displayed at the top of the Bender Setup menu.

- Set the protocol to BLM CMM (not BLM Data).

- Enter the path to the shared drive or folder in the NetPath field. Use the same location as the BLM setup. VTube accepts UNC names as well as regular paths with drive letters.

- Enter the IP address in the PING IP ADDRESS field if it is a fixed field. (This is not required. It allows VTube to ping the address to see if the network location is active before trying to open communications.)

- Most BLM benders handle Positive rotations as Clockwise, so you will probably need to enter "YES" for this option (so that the rotations are not corrected in the wrong direction).

- Press Close to save the settings. VTube will save these values to a persistent configuration file that will not change unless you change them in this grid.

|

|

NEWER BLM CMM PROTOCOL: How to SEND CORRECTION Data to the BLM Control from VTube-LASER

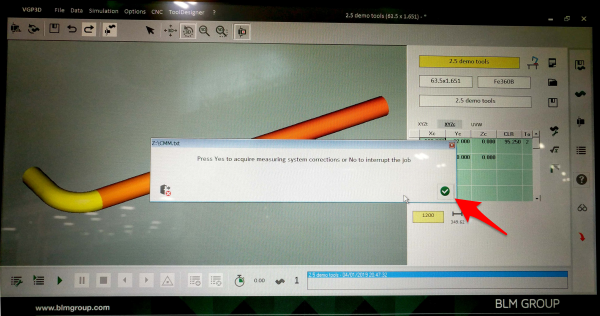

Bend the Part on the BLM then Create the CMM.txt File

Click on the measuring center image to to right of the part number.

Press the checkmark button to save a new CMM.txt file to Z: drive.

(This step assumes that you have already mapped the shared network drive to Z drive in the VGP3D control.)

|

|

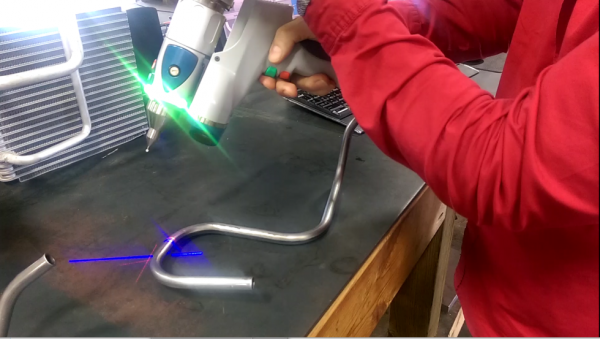

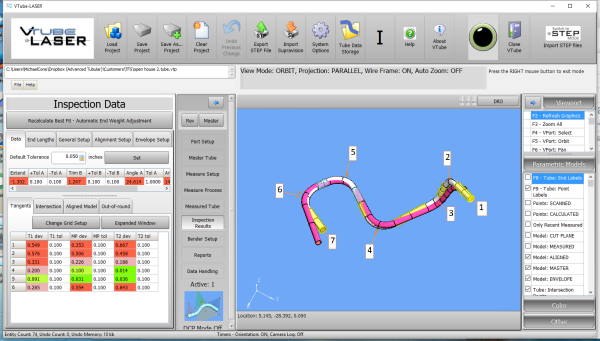

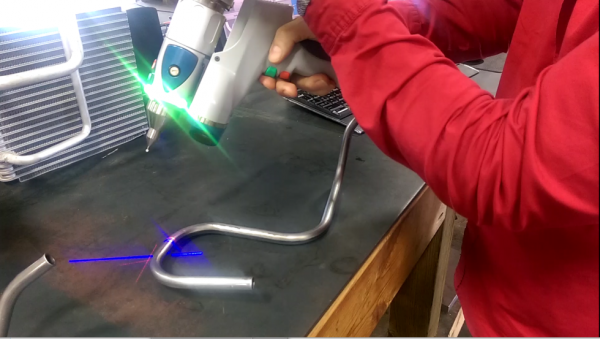

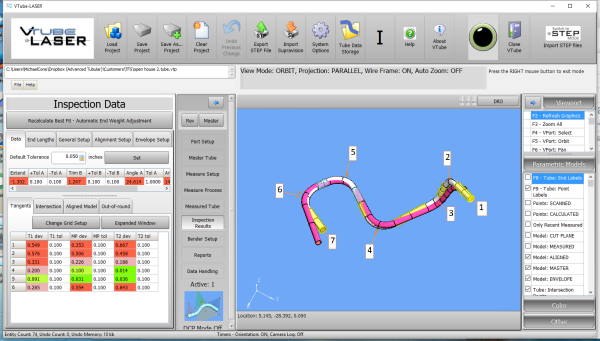

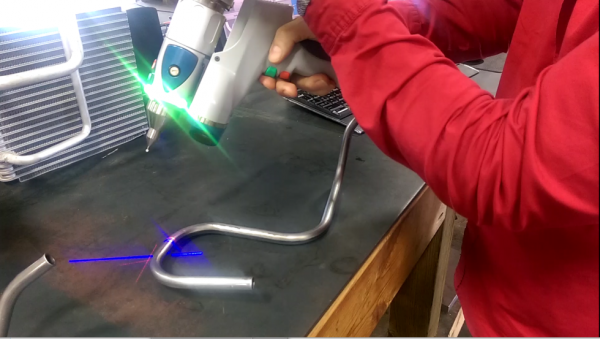

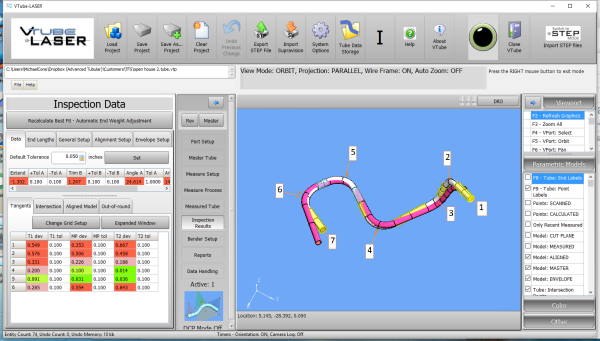

Measure the tube with VTube-LASER

Measure and align the tube to determine if it qualifies by falling within the envelope tolerance for the tube shape.

In the VTube-LASER screen shot, you see the actual result of the first tube not qualifying in shape. The red cells in the tangent point grid on the lower left show that the measured tube centerline is out-of-tolerance.

|

|

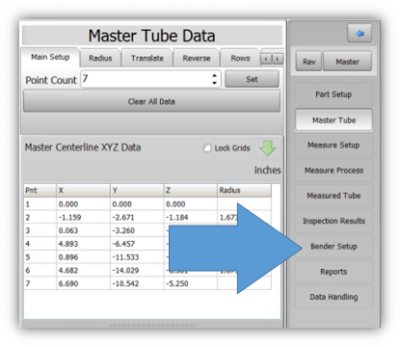

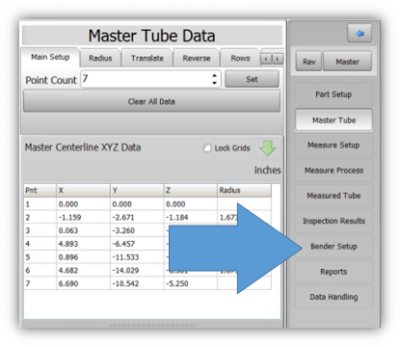

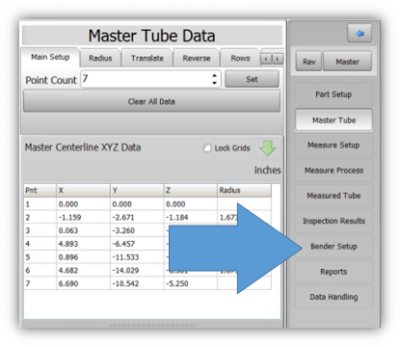

Correct the BLM with VTube-LASER - Enter BENDER SETUP

|

Follow these steps in the VTube-LASER:

Press the "BENDER SETUP button in the Navigation Pane.

|

|

INITIAL RECALL Setup of Bender Setup Window

|

These steps assume that you have programmed a part into the bender, and that you have measured and aligned a part.

STEP 1 - Set the correct bender number at the top of the window. The BLM CMM bender should display if you have already setup the bender protocol in the Benderlink grid.

STEP 2 - Click on the "RECALL LRA from BENDER" button.

|

|

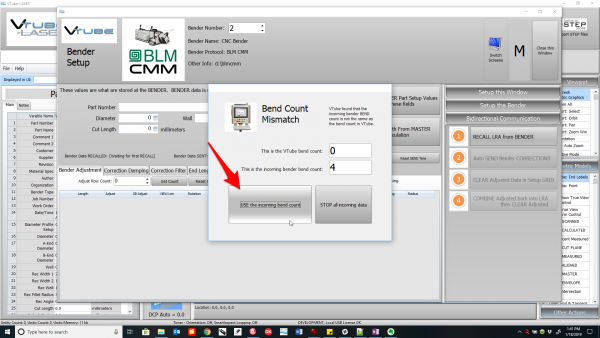

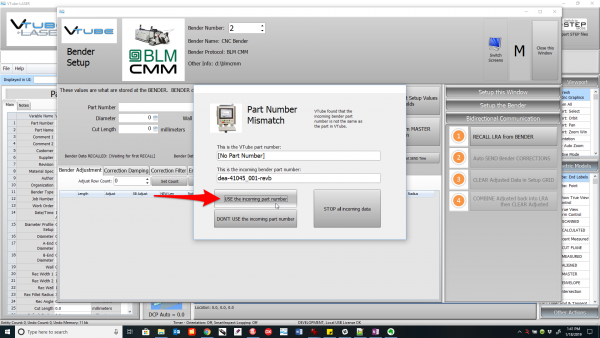

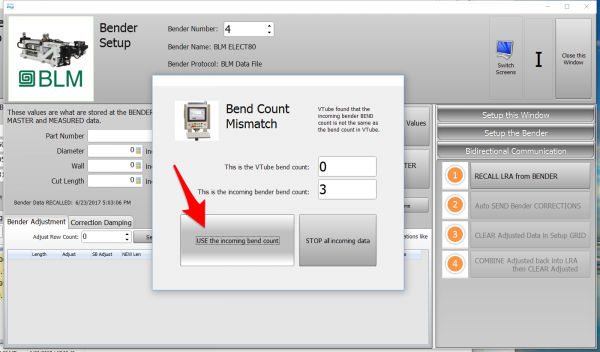

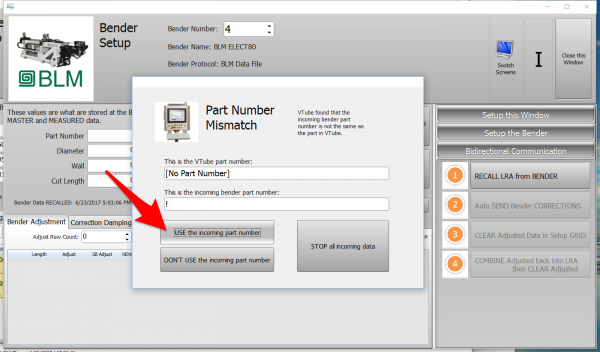

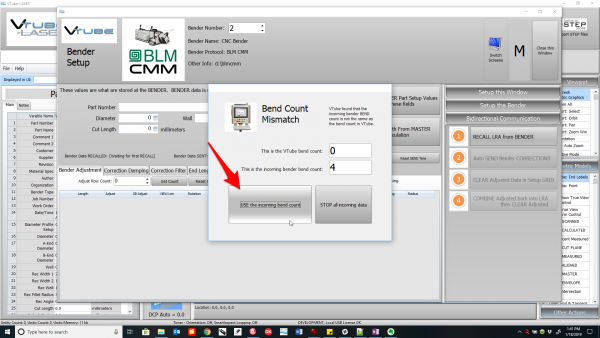

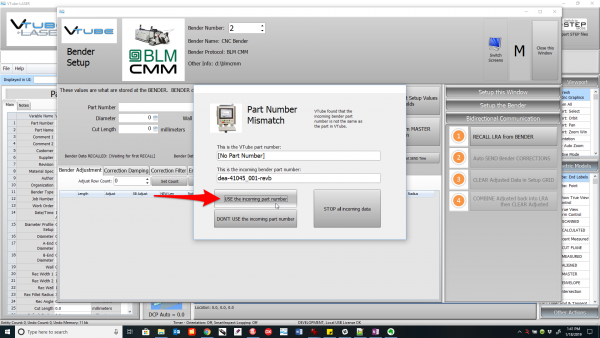

RECALL Warning Boxes

|

VTube-LASER will probably warn you that the incoming data count and part number does not match what is in VTube-LASER.

- It is very important that you allow the incoming bender data to increase the bend count to whatever is at the bender.

- If you want the Part Number at the bender to be left untouched, then just accept the incoming part number and use it for transfer from this point forward.

|

|

THE BLUE COLUMNS SHOULD MATCH THE BLM XYZc DATA AFTER THE RECALL

|

After the RECALL, the blue columns should show the data that is programmed in the BLM control.

This ensures that corrections are being made to the correct foundational data. If the blue column data does not match the bender at correction time, then it is probable that the bender will not be corrected properly.

|

|

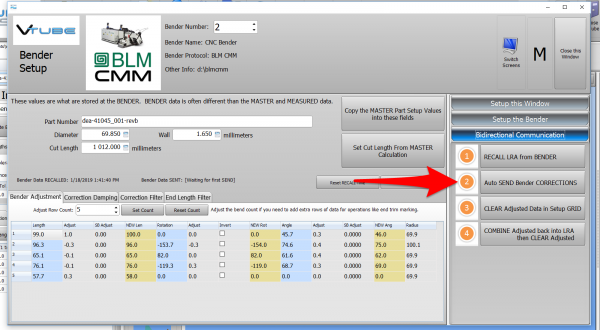

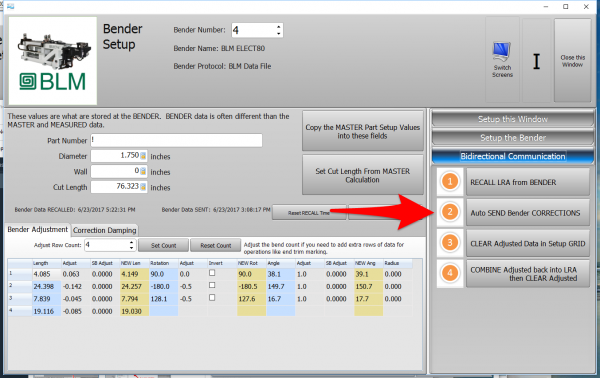

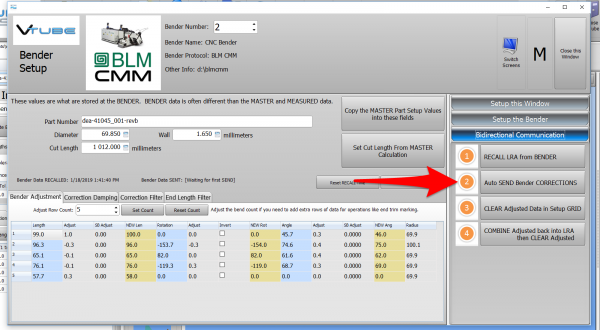

SEND THE CORRECTIONS INTO THE BLM CMM FILE

|

SAVE the Correction data to the file for the BLM CMM.txt file by pressing AUTO SEND BENDER CORRECTIONS.

STEP 1 - Click on Bidirectional Communication

STEP 2 - Click on AUTO SEND BENDER CORRECTIONS.

This will change the contents of the BLM CMM.txt file to the values in the ORANGE cells.

|

|

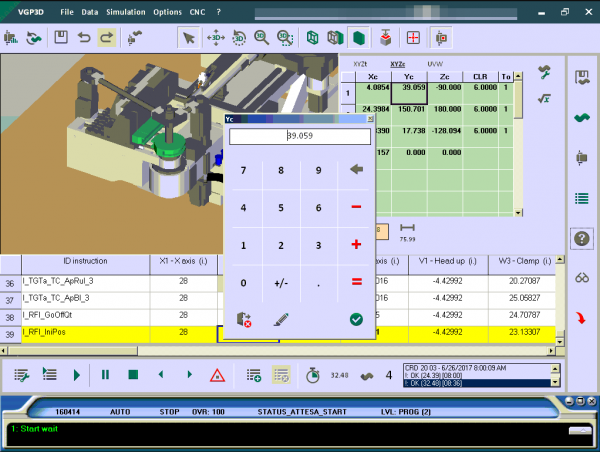

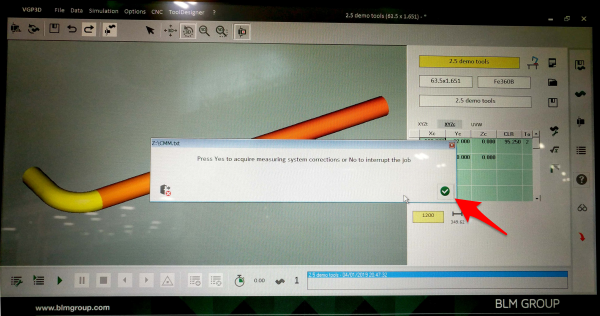

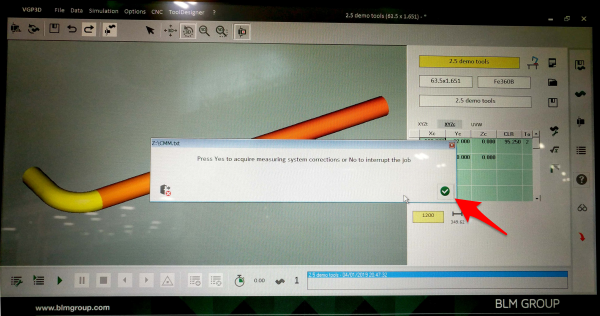

AT THE BLM, PRESS the CHECKMARK Button

|

If you saved the orange columns of data from VTube-LASER to the CMM.txt file, then it is very important to press the checkmark "yes" button for BLM to import the new CMM.txt file data.

After you press the checkmark button, the new data will display in the XYZc menu grid.

It's a good idea to cross-check a value (like the first bend angle) to be sure that the new data was imported correctly.

|

|

SIMULATE and RUN

|

- Run the simulator with the new data.

- Bend the corrected part.

- Press the measuring center icon in the upper right corner to build the CMM.txt file in Z drive.

- Take the part back to VTube-LASER to measure it again for qualification.

|

|

IMPORTANT RULES for CORRECTIONS LOOPS

- A RECALL from the BLM must be performed first. VTube will not build a NEW CMM.txt file during corrections.

- Therefore, it is critical to create a CMM.txt file on Z drive at the VGP3D before walking over the measuring center.

- The number of bends must match in both VTube-LASER and the BLM CMM.txt file.

- While the corrections loop does not use the UVW data from the VGP3D control for corrections, it will retain whatever UVW values are there. This prevents VTube-LASER from disturbing the UVW values during the corrections loop process.

- If you change the part number, diameter, wall thickness, or cut length, then those values will also change in VGP3D when you send the corrections.

|

|

NEWER BLM CMM PROTOCOL: How to SEND NEW XYZ Data to the BLM Control from VTube-LASER

Create a Temporary CMM.txt file at the BLM VGP3D Control

Click on the measuring center image to to right of the part number.

Press the checkmark button to save a new CMM.txt file to Z: drive.

|

|

|

Go to the VTube-LASER software and...

- Choose the correct bender number.

- Click on "Setup this Window" in the office bar menu on the right.

|

|

- Click on COPY Master LRA to Setup LRA.

|

|

Send New Data to the Bender

- Press the Setup the Bender button in the Office toolbar.

|

|

- Press the AUTO SEND the MASTER XYZ + BLUE Columns button.

This will send MASTER XYZ + Radius data + the Blue Column LRA data values.

|

|

AT THE BLM, PRESS the CHECKMARK Button

|

Press the checkmark "yes" button for BLM to import the new CMM.txt file data.

|

|

OLDER LEGACY BLM DATA Protocol Section

LEGACY BLM DATA PROTOCOL: The Capabilities

- VTube-LASER RECALLS, MODIFIES, and SAVES data directly in ".BLM" files. A communications link can be setup through a standard Windows network connection.

- The communication is bi-directional to and from the bender. It is possible to RECALL data from the BLM using the .BLM file format.

- The data that is included in the BLM file that the BLM can read is the BENDER data (Xc axis, Yc Axis, Zc Axis). The data also includes the diameter and the cut length.

- The protocol does not send the RADIUS data. Sending radius data causes the VGP3D to reset the tools and rebuild all custom commands - so VTube-LASER avoids sending this data.

|

|

LEGACY BLM DATA PROTOCOL: Setup Benderlink at VTube-STEP or VTube-LASER

Entering Benderlink Setup

- Enter the VTube System Options menu.

- Enter the Measure 2 tab menu.

- Enter the Setup Benderlink Network menu.

|

|

Setup the Benderlink Network Grid for the BLM Bender

- Choose an unused row in the grid for a new BLM bender setup. (Click on the image at the right to see a zoomed image.)

- Assign a bender name that will help operators identify what this bender is. This text will be displayed at the top of the Bender Setup menu.

- Set the protocol to BLM Data.

- Enter the path to the shared drive or folder in the NetPath field. Use the same location as the BLM setup. VTube accepts UNC names as well as regular paths with drive letters.

- Enter the IP address in the PING IP ADDRESS field if it is a fixed field. (This is not required. It allows VTube to ping the address to see if the network location is active before trying to open communications.)

- Most BLM benders handle Positive rotations as Clockwise, so you will probably need to enter "YES" for this option (so that the rotations are not corrected in the wrong direction).

- Press Close to save the settings. VTube will save these values to a persistent configuration file that will not change unless you change them in this grid.

|

|

LEGACY BLM DATA PROTOCOL: How to SEND CORRECTION Data to the BLM Control from VTube-LASER

After Bending the Tube

Bend a tube then measure it with VTube-LASER.

Measure the tube with VTube-LASER

Measure and align the tube to determine if it qualifies by falling within the envelope tolerance for the tube shape.

In the VTube-LASER screen shot, you see the actual result of the first tube not qualifying in shape. The red cells in the tangent point grid on the lower left show that the measured tube centerline is out-of-tolerance.

|

|

Correct the BLM with VTube-LASER - Enter BENDER SETUP

|

Follow these steps in the VTube-LASER:

Press the "BENDER SETUP button in the Navigation Pane.

|

|

INITIAL RECALL Setup of Bender Setup Window

|

The first time in this window for a new part will require these steps before you can correct the BLM bender. These steps assume that you have programmed a part in the bender, and that you have measured and aligned a part.

STEP 1 - Set the correct bender number at the top of the window. The BLM bender should display if you have already setup the bender protocol in the Benderlink grid.

STEP 2 - Click on the "Bidirectional Communication" button.

STEP 3 - Click on the "RECALL LRA from BENDER" button.

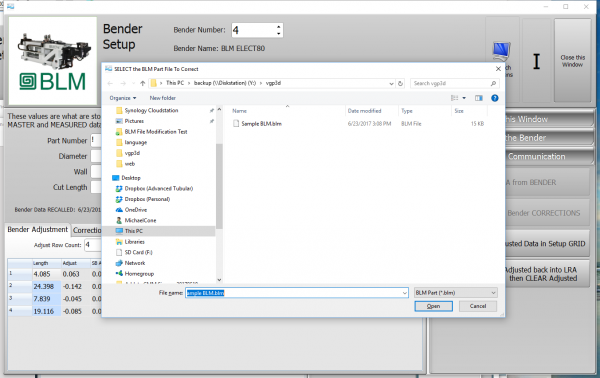

STEP 4 - Select the BLM file to open.

|

|

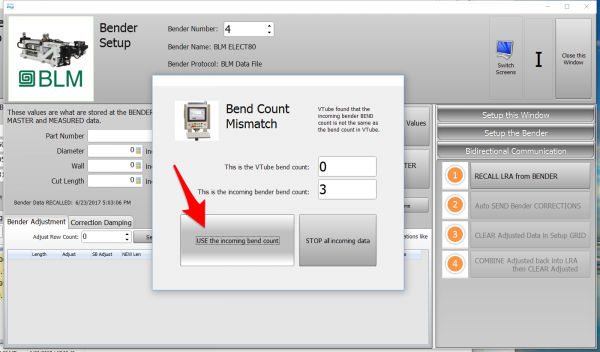

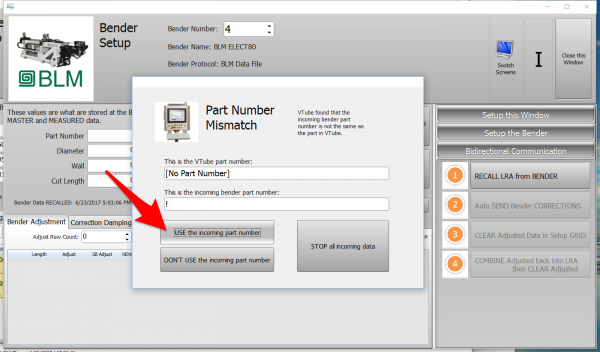

RECALL Warning Boxes

|

VTube-LASER will probably warn you that the incoming data count and part number does not match what is in VTube-LASER.

- It is very important that you allow the incoming bender data to increase the bend count to whatever is at the bender.

- If you want the Part Number at the bender to be left untouched, then just accept the incoming part number and use it for transfer from this point forward.

|

|

THE BLUE COLUMNS SHOULD MATCH THE BLM XYZc DATA AFTER THE RECALL

|

After the RECALL, the blue columns should show the data that is programmed in the BLM control.

This ensures that corrections are being made to the correct foundational data. If the blue column data does not match the bender at correction time, then it is probable that the bender will not be corrected properly.

|

|

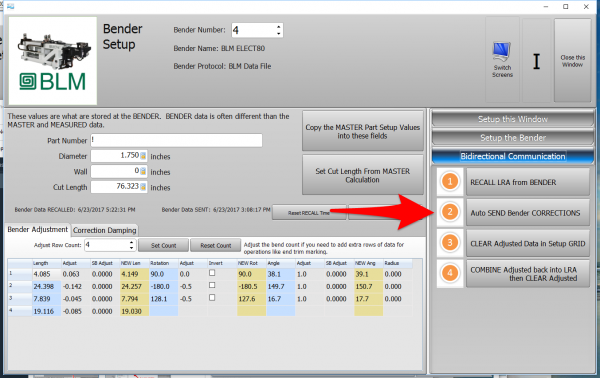

MERGE THE CORRECTIONS INTO THE BLM FILE

|

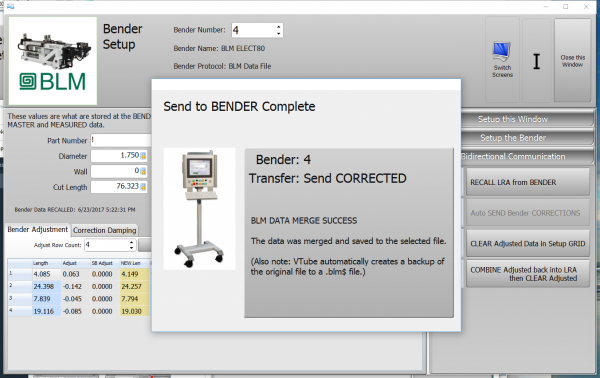

MERGE and SAVE the Correction data to the file for the BLM to import by pressing AUTO SEND BENDER CORRECTIONS.

STEP 1 - Click on Bidirectional Communication

STEP 2 - Click on AUTO SEND BENDER CORRECTIONS.

This will change the contents of the BLM file to the values in the ORANGE cells.

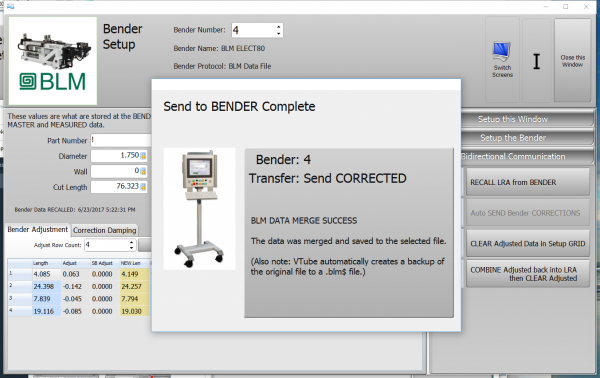

VTube also makes a backup of the current setup to a .blm$ file in case you want to undo that last correction.

|

|

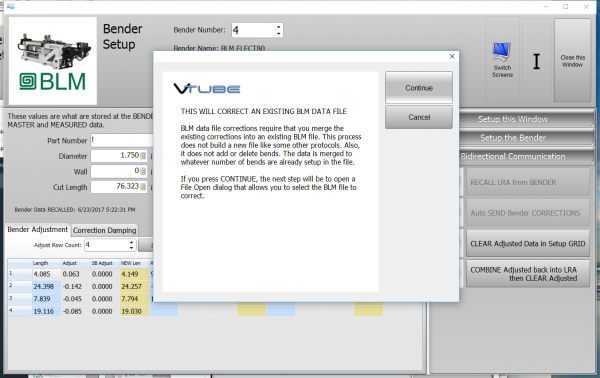

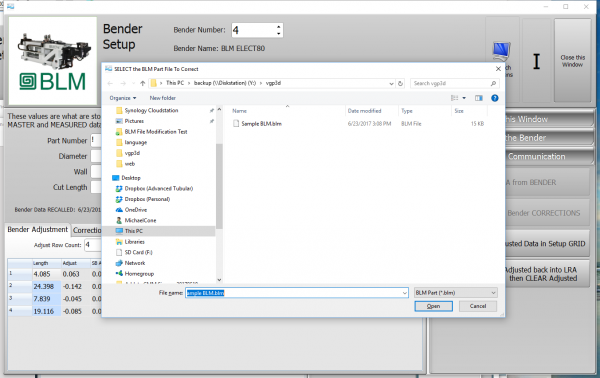

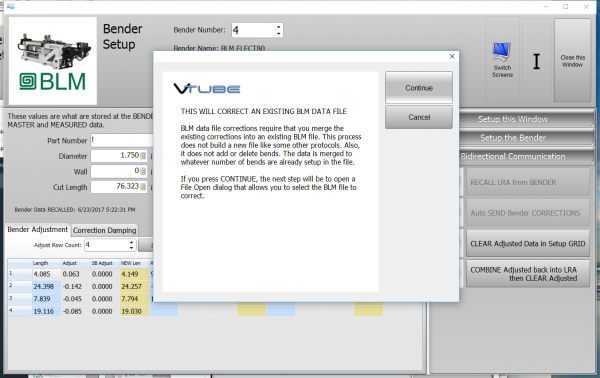

THESE ARE THE DIALOGS INSIDE THE AUTO SEND FEATURE

|

DIALOG 1 - The first dialog explains how communications works. This is for any user that needs to be reminded of how the merge process works.

DIALOG 2 - In the SAVE dialog, select the BLM file to merge data into, then press Save.

DIALOG 3 - VTube will show a timed message about the data merge.

|

|

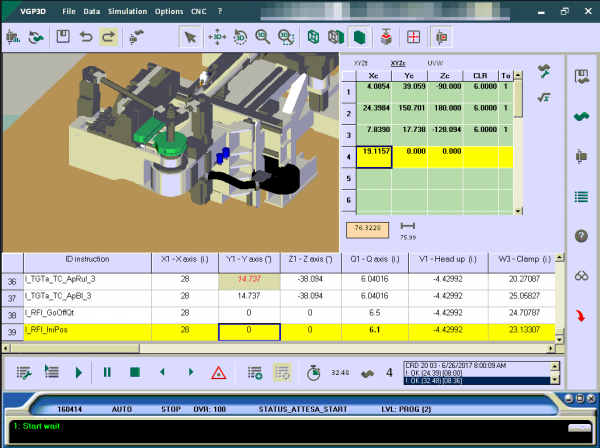

AFTER CORRECTION - LOAD THE NEW BLM FILE INTO THE VGP3D SOFTWARE AT THE BLM CONTROL

|

Load the BLM data VTube just saved into the VGP3D software.

|

|

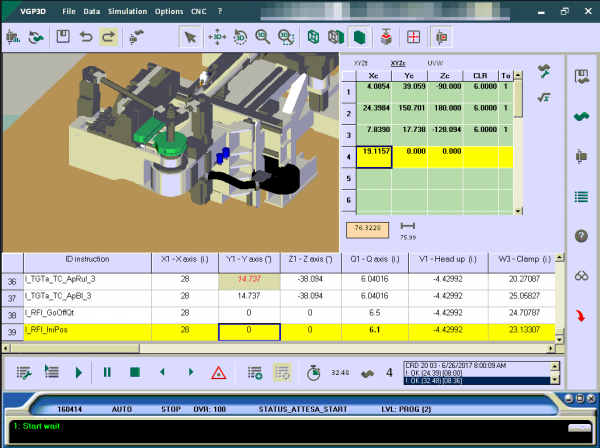

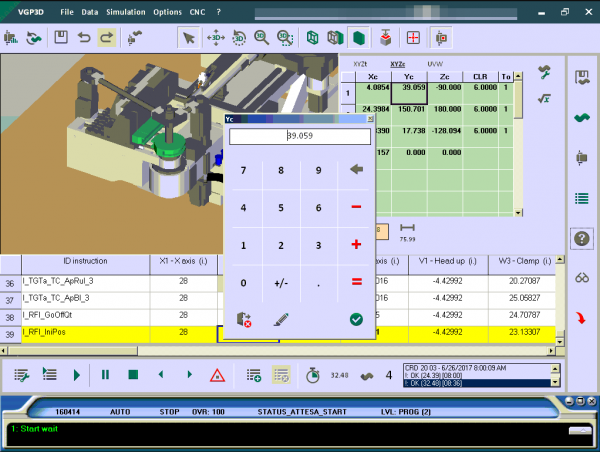

CRITICAL STEP: Recalculate the BLM Memory Following These Easy Steps

|

This next step is CRITICAL for proper operation of the BLM software. Without it, the new data will not be sent to the PLC.

- Touch any value on the XYZc grid.

- Without changing the value, press the Enter button (the pen button).

This will recalculate the internal BLM data.

IF YOU DO NOT TAKE THIS STEP, THEN THE XYZc VALUES ON THE SCREEN WILL NOT BE THE VALUES IN THE POINT TABLE THAT CONTROLS THE BENDER MOTION.

|

|

SIMULATE and RUN

|

- Run the simulator with the new data.

- Bend the corrected part.

- Take the part back to VTube-LASER to measure it again for qualification.

|

|

THE IMPORTANCE OF NOT RENAMING THE BLM FILE DURING CORRECTIONS

|

In order to retain custom moves already setup in VGP3D, it is important that you DO NOT CHANGE the .BLM filename during corrections.

Why?

The .BLM file that VTube-LASER modifies is accompanied by a point table file with the same filename but with a different filename extension of .OUT.

For example, on the BLM control, if there is a file "12345678.BLM" and you have bent the part, then there is a file "12345678.OUT" which represents the point table.

The .OUT file can contain custom lines that an operator programmed into the BLM for avoidance moves. If the .OUT file exists, then the SIMULATION CONTROL buttons (shown on the right) will be colored blue or green. If the .OUT file does not exist, then they will be grey - and the point table will need to be rebuilt.

|

|

Other Pages