VTube-LASER v2.8

|

Revision 2.8Release Date: Not Released Yet

|

BUILD 44 - April 11, 2017

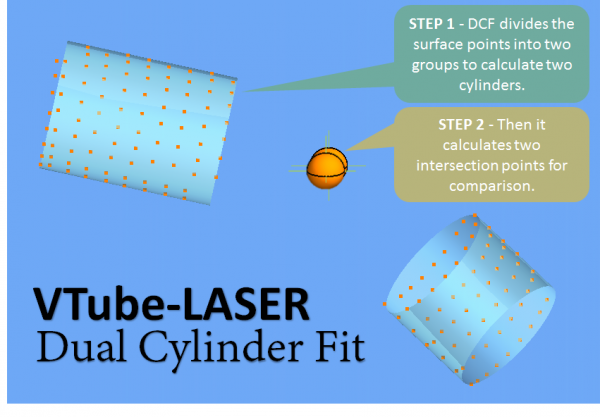

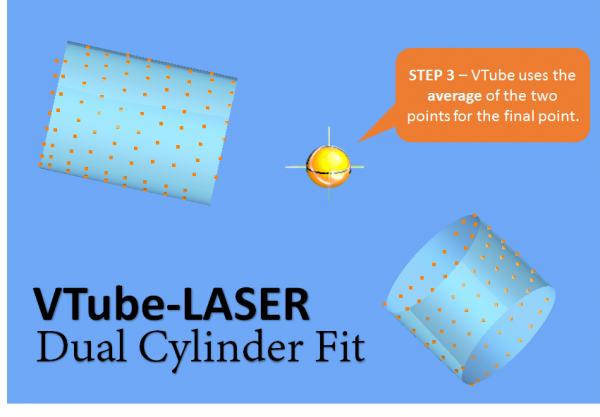

NEW: UNISCAN DCF (DUAL CYLINDER FIT) Feature

NEW: UNISCAN DCF (DUAL CYLINDER FIT) Feature

DCF is the major enhancement for VTube-LASER in version 2.8 because it replicates measuring the tube TWICE in one pass without the user noticing.This method helps to ensure repeatability of the cylinder measurements on-the-fly using a LASER scanner.

|

NEW: ADDED 3 NEW CYLINDER FIT CHECKS

NEW: ADDED 3 NEW CYLINDER FIT CHECKS

|

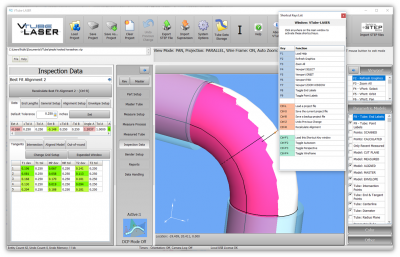

This window reports cylinder fit values that help you know if the cylinder measurement is good. CHECK 1 - MAXIMUM WOBBLE PREDICTIONThe Maximum Wobble value predicts how precise the surface data fits the cylinder. This was in previous versions, but now two cylinders must pass - not just one. And we've created a single new value to display at the top rather than multiple XY values. CHECK 2 - OD SURFACE TO CENTERLINEThe new OD Surface to Centerline value reports the low and high points on the measured diameter relative to the centerline. If the values get too far from each other (the "Delta"), then VTube-LASER will warn you. Also, the Out-of-round% is reported and used to qualify the cylinder fit. This is active for both LASER and ball probe. CHECK 3 - INTERSECTION PASS DISTANCEThe Intersection Pass Distance shows how near each intersecting 3D centerline comes to each other in 3D space. If the Nearest Pass value is more than the Intersection Error Tolerance, then VTube-LASER will warn you. This is active for both LASER and ball probe. CHECK 4 - DUAL CYLINDER FITAs mentioned above, because the DCF engine creates two cylinders, it always builds and compares the resulting intersection points from both cylinders. It warns you if they don't match well enough. |

NEW: CYLINDER FIT WINDOW is NOW COLOR-CODED

NEW: CYLINDER FIT WINDOW is NOW COLOR-CODED

|

The window is now color-coded to help you quickly determine where the problem lies in the data.

RED PANELThis would indicate a major problem in the cylinder fit calculation. VTube requires a remeasure of a straight section. |

GREEN PANELAll green indicates that no issues were found in all four checks. You can trust the calculation. |

Intersection Pass Distance Warning TestThis is an example of the Intersection Pass Distance warning test. |

NEW: Automatic ORBIT to TRUE VIEW of MEASURED CYLINDERS

NEW: Automatic ORBIT to TRUE VIEW of MEASURED CYLINDERS

|

We teach users to view the end scan on the screen before moving to the step. In previous versions, this required that you manually orbit the viewport so that you can see the end scans. From this version forward, VTube automatically orbits every straight TRUE to the screen so that you don't have to use the mouse to find that orientation. |

NEW: CONFIGURE CYLINDER FIT TOLERANCES ON-THE-FLY

NEW: CONFIGURE CYLINDER FIT TOLERANCES ON-THE-FLY

|

Users can now easily configure cylinder fit tolerances on-the-fly. |

NEW: CONFIGURE CYLINDER FIT QUALIFICATION VALUES

NEW: CONFIGURE CYLINDER FIT QUALIFICATION VALUES

| This a new group of qualification values in the Measure 1 tab menu of System Options. Most of these values are new to the VTube-LASER project file storage. |

NEW: Point Labels for All Models

NEW: Point Labels for All Models

| This version now shows point labels for all models drawn on the screen. |

NEW: ORBIT CONTROL Window

NEW: ORBIT CONTROL Window

|

This window lets you find any true or normal orientation for any line or bend in any model.

|

NEW: Redesigned Parametric Display Options Window

NEW: Redesigned Parametric Display Options Window

| The Parametric Display Options Window has been redesigned to include model colors and easier to use controls. |

NEW: Import TUBE DATA from ROMER CIMCORE DOCS .DS FILES

NEW: Import TUBE DATA from ROMER CIMCORE DOCS .DS FILES

| Import DOCS tube data in VTube-STEP mode. |

BUILD 20 - March 14, 2017

NEW: MantisHub Web Server Bug Tracking

NEW: MantisHub Web Server Bug Tracking

|

This version of VTube will allow you to choose to report software errors directly to our account at MantisHub.

|

BUILD 11 - February 15, 2017

NEW: "Default Tolerance Ends" Value

NEW: "Default Tolerance Ends" Value

|

The Default Tolerance Ends value is in the Inspection Data menu.

|

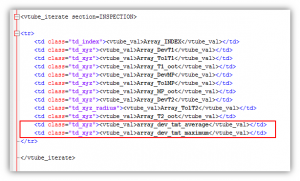

NEW: REPORT COMMANDS - Tangent Deviation AVERAGE and MAXIMUM Values

NEW: REPORT COMMANDS - Tangent Deviation AVERAGE and MAXIMUM Values

BUILD 19 - February 22, 2017

ENHANCED: Winton WMC Communications Improvement

ENHANCED: Winton WMC Communications Improvement

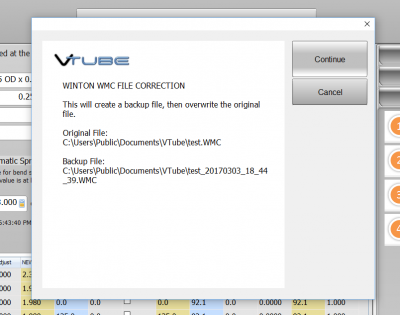

New Process Flow for Winton WMC CorrectionThis image shows the overall process for correction of Winton WMC files.

|

UPDATED: Japanese Translation for User Interface

UPDATED: Japanese Translation for User Interface

|

The Japanese translation of the UI was updated from version 2.6.

|

Other Pages

- Back to VTube-LASER

- Back to VTube Software Updates (for LASER Mode)

- See also VTube-STEP

- See also VTube-STEP Revisions

- See VTube-LASER Customer Support Page to download the latest version.

- See VTube-LASER Cut Planes

- See the tutorial on DCP - Diameter Cut Planes

- See How to Measure Tubes Attached to an Evaporator with the DCP Feature