Difference between revisions of "VTube-LASER v2.8"

(→25px NEW: REPORT COMMANDS - Tangent Deviation AVERAGE and MAXIMUM Values) |

(→25px FIX: Out-of-round % Tolerance Reporting) |

||

| (180 intermediate revisions by one user not shown) | |||

| Line 6: | Line 6: | ||

==Revision 2.8== | ==Revision 2.8== | ||

| − | Release Date: | + | Original Release Date: April 19, 2017<br> |

| + | Latest Build: 59 - April 21, 2017 | ||

* Back to [[VTube-LASER]] | * Back to [[VTube-LASER]] | ||

* Back to [[VTube Software Updates]] (for LASER Mode) | * Back to [[VTube Software Updates]] (for LASER Mode) | ||

| + | * Download in updates the [https://www.advancedtubular.com/customers/vtube/ VTube-LASER Support Page] | ||

| Line 20: | Line 22: | ||

__TOC__ | __TOC__ | ||

| + | |||

| + | =BUILD 44 - April 11, 2017= | ||

| + | |||

| + | ==[[image:Check.jpg|25px]] NEW: UNISCAN DCF (DUAL CYLINDER FIT) Feature== | ||

| + | |||

| + | <table cellpadding=10 width=900> | ||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | '''DCF is the major enhancement for VTube-LASER in this version because it replicates measuring the tube TWICE in one pass without the user noticing.'''<br><br> | ||

| + | [[image:vtube-laser_v2.8_cylinderfit_DualCylinderFit.png]]<br><br> | ||

| + | This method helps to ensure repeatability of the cylinder measurements on-the-fly using a LASER scanner. | ||

| + | <br><br> | ||

| + | '''Read details about this new feature here: [[DCF - Dual Cylinder Fit]]''' | ||

| + | <td> | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:vtube-laser_v2.8_DCF_logo.png|500px]]<br><br> | ||

| + | </tr> | ||

| + | </table> | ||

| + | <br><br> | ||

| + | |||

| + | ==[[image:Check.jpg|25px]] NEW: ADDED 3 NEW CYLINDER FIT CHECKS== | ||

| + | |||

| + | <table cellpadding=10 width=1100> | ||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | This window reports cylinder fit values that help you know if the cylinder measurement is good.<br><br> | ||

| + | When using Uniscan mode, VTube cylinders must now pass a total of FOUR checks to be qualified as good cylinder scans. (All previous versions only used CHECK 1.) | ||

| + | <br><br> | ||

| + | <br><br> | ||

| + | '''Read details about the four checks here: [[DCF - Dual Cylinder Fit]]''' | ||

| + | <td> | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:vtube-laser_v2.8_cylinderfit_window_sections.png|700px]] | ||

| + | </tr> | ||

| + | </table> | ||

| + | <br><br> | ||

| + | |||

| + | ==[[image:Check.jpg|25px]] NEW: CYLINDER FIT WINDOW is NOW COLOR-CODED== | ||

| + | <table cellpadding=10 width=1100> | ||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | The window is now color-coded to help you quickly determine where the problem lies in the data. | ||

| + | <br><br> | ||

| + | '''Read details about the panel colors here: [[DCF - Dual Cylinder Fit]]''' | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:vtube-laser_v2.8_cylinderfitwindow_redpanel.png|200px]] | ||

| + | [[image:vtube-laser_v2.8_cylinderfitwindow_greenpanel.png|200px]] | ||

| + | [[image:vtube-laser_v2.8_IntersectionPassDistance.png|200px]] | ||

| + | </tr> | ||

| + | </table> | ||

| + | <br><br> | ||

| + | |||

| + | ==[[image:Check.jpg|25px]] NEW: Automatic ORBIT to TRUE VIEW of MEASURED CYLINDERS== | ||

| + | |||

| + | <table cellpadding=10 width=1000> | ||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | We teach users to view the end scan on the screen before moving to the step. In previous versions, this required that you manually orbit the viewport so that you can see the end scans.<br><br> | ||

| + | <h3>From this version forward, VTube automatically orbits every straight TRUE to the screen so that you don't have to use the mouse to find that orientation.</h3><td> | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:vtube-laser_v2.8_automatic_truecylinders.png|700px]] | ||

| + | </tr> | ||

| + | </table> | ||

| + | <br><br> | ||

| + | |||

| + | ==[[image:Check.jpg|25px]] NEW: CONFIGURE CYLINDER FIT TOLERANCES ON-THE-FLY== | ||

| + | |||

| + | <table cellpadding=10 width=1000> | ||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | Users can now easily configure cylinder fit tolerances on-the-fly. <br><br> | ||

| + | If a tolerance is too tight for a tube straight that has a lot of deformation, then you can easily increase the tolerance at any time.<td> | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:vtube-laser_v2.8_CylinderFit_GearButton.png|700px]] | ||

| + | </tr> | ||

| + | </table> | ||

| + | <br><br> | ||

| + | |||

| + | |||

| + | |||

| + | ==[[image:Check.jpg|25px]] NEW: ADDED CYLINDER FIT QUALIFICATION VALUES== | ||

| + | |||

| + | <table cellpadding=10 width=1000> | ||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | This a new group of qualification values in the Measure 1 tab menu of System Options. Most of these values are new to the VTube-LASER project file storage.<td> | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:vtube-laser_v2.8_new_cylinder_fit_qualification_values.png|400px]] | ||

| + | </tr> | ||

| + | </table> | ||

| + | <br><br> | ||

| + | |||

| + | ==[[image:Check.jpg|25px]] NEW: Point Labels for All Models== | ||

| + | |||

| + | <table cellpadding=10 width=1000> | ||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | This version now shows point labels for all models drawn on the screen.<td> | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:vtube-laser_v2.8_point_labels_for_all_models.png|400px]] | ||

| + | </tr> | ||

| + | </table> | ||

| + | <br><br> | ||

| + | |||

| + | |||

| + | ==[[image:Check.jpg|25px]] NEW: ORBIT CONTROL Window== | ||

| + | |||

| + | <table cellpadding=10 width=1000> | ||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | This window lets you find any true or normal orientation for any line or bend in any model. | ||

| + | <br><br> | ||

| + | Click on the image below to see a video:<br> | ||

| + | |||

| + | [[image:vtube-laser_v2.8_orbitcontrolwindow_video.png|300px|link=http://www.advancedtubular.com/vtube-laser/vtube-laser_v2.8_orbitcontrolwindow.mp4]] | ||

| + | |||

| + | <td> | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:vtube-laser_v2.8_orbitcontrolwindows.png|400px]] | ||

| + | </tr> | ||

| + | </table> | ||

| + | <br><br> | ||

| + | |||

| + | |||

| + | |||

| + | ==[[image:Check.jpg|25px]] NEW: TRUE VIEW TRANSFORM Window== | ||

| + | |||

| + | <table cellpadding=10 width=1000> | ||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | This window lets you transform the orientation of any straight or bend in any model to true to the XY plane.<br><br>This is different than changing the orbit - which just rotates around the part. This actually rotates the part to the XY plane by changing the part centerline coordinates. | ||

| + | <br><br> | ||

| + | <td> | ||

| + | [[image:vtube-laser_v2.8_trueview_transform.png|400px]] | ||

| + | </tr> | ||

| + | </table> | ||

| + | <br><br> | ||

| + | |||

| + | ==[[image:Check.jpg|25px]] NEW: Redesigned Parametric Display Options Window== | ||

| + | |||

| + | <table cellpadding=10 width=1000> | ||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | The Parametric Display Options Window has been redesigned to include model colors and easier to use controls.<td> | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:vvtube-laser_v2.8_parametricdisplayoptions.png|600px]] | ||

| + | </tr> | ||

| + | </table> | ||

| + | <br><br> | ||

| + | |||

| + | |||

| + | ==[[image:Check.jpg|25px]] NEW: Import TUBE DATA from ROMER CIMCORE DOCS .DS FILES== | ||

| + | |||

| + | <table cellpadding=10 width=1000> | ||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | Import DOCS tube data in VTube-STEP mode.<td> | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:VTube-STEP_v2.8_ImportDOCS.png|400px]] | ||

| + | </tr> | ||

| + | </table> | ||

| + | <br><br> | ||

| + | |||

| + | |||

| + | ==[[image:Check.jpg|25px]] NEW: PRECISION WEIGHT CONTROL Alignment== | ||

| + | |||

| + | <table cellpadding=10 width=1000> | ||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | Customers asked for additional control for the weighting that is easier to use than 321 Plane-Line-Point. This is the answer to that request. | ||

| + | |||

| + | We've added PRECISION WEIGHT CONTROL alignment that allows you to completely turn off certain sections of the tube for alignment or give emphasis to any section just by setting weights from 0 to 1000.<br><br> | ||

| + | A weight of "0" tells VTube to ignore the point completely in alignment. A weight of 1 means give it 1 times the normal weight. A weight of 2 means give it double weight. | ||

| + | |||

| + | This shows emphasis given to end A. Note that some of the alignment weights are ZERO - which means that those points are ignored in the alignment.<td> | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:VTube-STEP_v2.8_precisionweightcontrol_alignment_enda.png|600px]] | ||

| + | </tr> | ||

| + | </table> | ||

| + | |||

| + | <table cellpadding=10 width=1000> | ||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | This shows emphasis given to end B.<td> | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:VTube-STEP_v2.8_precisionweightcontrol_alignment_endb.png|600px]] | ||

| + | </tr> | ||

| + | </table> | ||

| + | |||

| + | <table cellpadding=10 width=1000> | ||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | This shows emphasis given to the middle straight.<td> | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:VTube-STEP_v2.8_precisionweightcontrol_alignment_middle.png|600px]] | ||

| + | </tr> | ||

| + | </table> | ||

| + | <br><br> | ||

| + | |||

| + | =BUILD 20 - March 14, 2017= | ||

| + | |||

| + | ==[[image:Check.jpg|25px]] NEW: MantisHub Web Server Bug Tracking== | ||

| + | |||

| + | <table cellpadding=10 width=900> | ||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | This version of VTube will allow you to choose to report software errors directly to our account at MantisHub. | ||

| + | <br><br> | ||

| + | This service will allow us to track bug issues with VTube-STEP and VTube-LASER. | ||

| + | <br><br> | ||

| + | <td> | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:MantisHubLogo.png|400px]] | ||

| + | </tr> | ||

| + | </table> | ||

| + | <br><br> | ||

=BUILD 11 - February 15, 2017= | =BUILD 11 - February 15, 2017= | ||

| Line 48: | Line 280: | ||

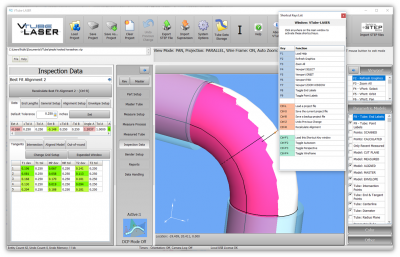

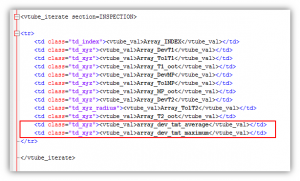

Two new array values are available for reports: AVERAGE deviation and MAXIMUM deviation. | Two new array values are available for reports: AVERAGE deviation and MAXIMUM deviation. | ||

<br><br> | <br><br> | ||

| − | See the example result in the report on the right.<br><br> | + | The new commands are |

| + | * <code>array_dev_tmt_average</code><br> | ||

| + | * <code>array_dev_tmt_maximum</code> | ||

| + | <br><br> | ||

| + | See the example result in the report on the right, and the report template source to create this table shown below.<br><br> | ||

[[image:vtl-2.8_inspection data tangent average and maximum html sample.png|300px]] | [[image:vtl-2.8_inspection data tangent average and maximum html sample.png|300px]] | ||

| + | |||

| + | <br><br> | ||

| + | |||

<td> | <td> | ||

| Line 59: | Line 298: | ||

<br><br> | <br><br> | ||

| − | = | + | =BUILD 19 - February 22, 2017= |

| + | ==[[image:Check.jpg|25px]] ENHANCED: Winton WMC Communications Improvement== | ||

| − | <br><br><br><br> | + | |

| + | |||

| + | <table cellpadding=10 width=900> | ||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

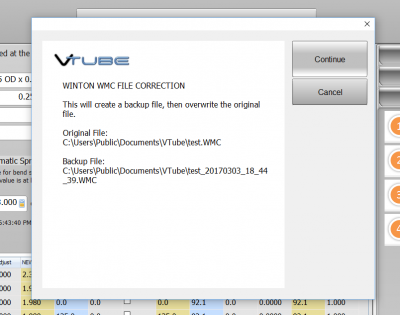

| + | The process for corrections to Winton WMC files were clarified with dialogs that make it very clear what VTube-LASER Bender Setup is doing during the Winton WMC correction process. | ||

| + | <br><br> | ||

| + | [[image:winton bender.png|300px]]<br><br> | ||

| + | ===1 - NEW HELP DIALOGS=== | ||

| + | Steps 2 and 5 are new. They carefully explain what is happening during the correction process.<br><br> | ||

| + | |||

| + | ===2 - NEW BACKUP CREATED=== | ||

| + | Step 5 also explains that a BACKUP file is created during the process. This allows operators to always recover to the previous data if something goes wrong in the correction process. (The creation of a backup file is new in this version.) | ||

| + | <br><br> | ||

| + | |||

| + | <td> | ||

| + | </td> | ||

| + | <td> | ||

| + | Immediately after the user presses the Auto Correction button, this dialog appears (see step 2 below):<br><br> | ||

| + | [[image:vtl_v2.8_winton_correction_existing_dialog.png|400px]]<br><br> | ||

| + | |||

| + | Immediately after the user presses the Exit and Save setup data button, this dialog appears (see step 4 below):<br><br> | ||

| + | [[image:vtl_v2.8_winton_correction_overwrite_backup_dialog.png|400px]]<br><br> | ||

| + | </tr> | ||

| + | </table> | ||

| + | <br><br> | ||

| + | |||

| + | |||

| + | <table cellpadding=10 width=900> | ||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | |||

| + | ===New Process Flow for Winton WMC Correction=== | ||

| + | This image shows the overall process for correction of Winton WMC files. | ||

| + | <br><br> | ||

| + | <td> | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:vtl_v2.8_winton_correction_process.png|600px]]<br><br> | ||

| + | </tr> | ||

| + | </table> | ||

| + | <br><br> | ||

| + | |||

| + | ==[[image:Check.jpg|25px]] UPDATED: Japanese Translation for User Interface== | ||

| + | |||

| + | <table cellpadding=10 width=1200> | ||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | The Japanese translation of the UI was updated from version 2.6. | ||

| + | <br><br> | ||

| + | The new Cut Plane control (with the Diameter Cut Plane features) and the new Shortcut Key window is now translated into Japanese. | ||

| + | <br><br> | ||

| + | <td> | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:vtl-2.8 japanese diameter cut plane.png|800px]] | ||

| + | </tr> | ||

| + | </table> | ||

| + | <br><br> | ||

| + | |||

| + | |||

| + | |||

| + | =BUILD 60 - April 26, 2017= | ||

| + | |||

| + | ==[[image:Check.jpg|25px]] FIX: Out-of-round % Tolerance Reporting== | ||

| + | |||

| + | <table cellpadding=10 width=900> | ||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | The OOR% tolerance value was incorrected compared to the HIGH value in the surface to centerline distance. This has been repaired. | ||

| + | <br><br> | ||

| + | <td> | ||

| + | </td> | ||

| + | <td> | ||

| + | </tr> | ||

| + | </table> | ||

| + | <br><br> | ||

| + | |||

| + | ==[[image:Check.jpg|25px]] NEW: More Invdividual Cylinder Fit Data Window Pass/Fail Colors== | ||

| + | |||

| + | <table cellpadding=10 width=900> | ||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | Each value that is compared to a tolerance is now shown in the Cylinder Fit Data window with a unique PASS/FAIL - GREEN/RED coloring. This helps users identify exactlhy which value caused the cylinder fit failure. | ||

| + | <br><br> | ||

| + | <td> | ||

| + | </td> | ||

| + | <td> | ||

| + | </tr> | ||

| + | </table> | ||

| + | <br><br> | ||

=Other Pages= | =Other Pages= | ||

| Line 70: | Line 400: | ||

* See also [[VTube-STEP Revisions]] | * See also [[VTube-STEP Revisions]] | ||

* See [http://www.advancedtubular.com/customers/vtube VTube-LASER Customer Support Page] to download the latest version. | * See [http://www.advancedtubular.com/customers/vtube VTube-LASER Customer Support Page] to download the latest version. | ||

| − | * See [[ | + | * See the tutorial on [[DCF - Dual Cylinder Fit]] |

* See the tutorial on [[DCP - Diameter Cut Planes]] | * See the tutorial on [[DCP - Diameter Cut Planes]] | ||

| + | * See [[VTube-LASER Cut Planes]] | ||

* See [[How to Measure Tubes Attached to an Evaporator]] with the DCP Feature | * See [[How to Measure Tubes Attached to an Evaporator]] with the DCP Feature | ||

Latest revision as of 02:49, 27 April 2017

|

Revision 2.8Original Release Date: April 19, 2017

|

BUILD 44 - April 11, 2017

NEW: UNISCAN DCF (DUAL CYLINDER FIT) Feature

NEW: UNISCAN DCF (DUAL CYLINDER FIT) Feature

|

DCF is the major enhancement for VTube-LASER in this version because it replicates measuring the tube TWICE in one pass without the user noticing. |

NEW: ADDED 3 NEW CYLINDER FIT CHECKS

NEW: ADDED 3 NEW CYLINDER FIT CHECKS

|

This window reports cylinder fit values that help you know if the cylinder measurement is good. |

NEW: CYLINDER FIT WINDOW is NOW COLOR-CODED

NEW: CYLINDER FIT WINDOW is NOW COLOR-CODED

|

The window is now color-coded to help you quickly determine where the problem lies in the data.

|

NEW: Automatic ORBIT to TRUE VIEW of MEASURED CYLINDERS

NEW: Automatic ORBIT to TRUE VIEW of MEASURED CYLINDERS

|

We teach users to view the end scan on the screen before moving to the step. In previous versions, this required that you manually orbit the viewport so that you can see the end scans. From this version forward, VTube automatically orbits every straight TRUE to the screen so that you don't have to use the mouse to find that orientation. |

NEW: CONFIGURE CYLINDER FIT TOLERANCES ON-THE-FLY

NEW: CONFIGURE CYLINDER FIT TOLERANCES ON-THE-FLY

|

Users can now easily configure cylinder fit tolerances on-the-fly. |

NEW: ADDED CYLINDER FIT QUALIFICATION VALUES

NEW: ADDED CYLINDER FIT QUALIFICATION VALUES

| This a new group of qualification values in the Measure 1 tab menu of System Options. Most of these values are new to the VTube-LASER project file storage. |

NEW: Point Labels for All Models

NEW: Point Labels for All Models

| This version now shows point labels for all models drawn on the screen. |

NEW: ORBIT CONTROL Window

NEW: ORBIT CONTROL Window

|

This window lets you find any true or normal orientation for any line or bend in any model.

|

NEW: TRUE VIEW TRANSFORM Window

NEW: TRUE VIEW TRANSFORM Window

|

This window lets you transform the orientation of any straight or bend in any model to true to the XY plane. |

NEW: Redesigned Parametric Display Options Window

NEW: Redesigned Parametric Display Options Window

| The Parametric Display Options Window has been redesigned to include model colors and easier to use controls. |

NEW: Import TUBE DATA from ROMER CIMCORE DOCS .DS FILES

NEW: Import TUBE DATA from ROMER CIMCORE DOCS .DS FILES

| Import DOCS tube data in VTube-STEP mode. |

NEW: PRECISION WEIGHT CONTROL Alignment

NEW: PRECISION WEIGHT CONTROL Alignment

|

Customers asked for additional control for the weighting that is easier to use than 321 Plane-Line-Point. This is the answer to that request. We've added PRECISION WEIGHT CONTROL alignment that allows you to completely turn off certain sections of the tube for alignment or give emphasis to any section just by setting weights from 0 to 1000. |

| This shows emphasis given to end B. |

| This shows emphasis given to the middle straight. |

BUILD 20 - March 14, 2017

NEW: MantisHub Web Server Bug Tracking

NEW: MantisHub Web Server Bug Tracking

|

This version of VTube will allow you to choose to report software errors directly to our account at MantisHub.

|

BUILD 11 - February 15, 2017

NEW: "Default Tolerance Ends" Value

NEW: "Default Tolerance Ends" Value

|

The Default Tolerance Ends value is in the Inspection Data menu.

|

NEW: REPORT COMMANDS - Tangent Deviation AVERAGE and MAXIMUM Values

NEW: REPORT COMMANDS - Tangent Deviation AVERAGE and MAXIMUM Values

BUILD 19 - February 22, 2017

ENHANCED: Winton WMC Communications Improvement

ENHANCED: Winton WMC Communications Improvement

New Process Flow for Winton WMC CorrectionThis image shows the overall process for correction of Winton WMC files.

|

UPDATED: Japanese Translation for User Interface

UPDATED: Japanese Translation for User Interface

|

The Japanese translation of the UI was updated from version 2.6.

|

BUILD 60 - April 26, 2017

FIX: Out-of-round % Tolerance Reporting

FIX: Out-of-round % Tolerance Reporting

|

The OOR% tolerance value was incorrected compared to the HIGH value in the surface to centerline distance. This has been repaired.

|

NEW: More Invdividual Cylinder Fit Data Window Pass/Fail Colors

NEW: More Invdividual Cylinder Fit Data Window Pass/Fail Colors

|

Each value that is compared to a tolerance is now shown in the Cylinder Fit Data window with a unique PASS/FAIL - GREEN/RED coloring. This helps users identify exactlhy which value caused the cylinder fit failure.

|

Other Pages

- Back to VTube-LASER

- Back to VTube Software Updates (for LASER Mode)

- See also VTube-STEP

- See also VTube-STEP Revisions

- See VTube-LASER Customer Support Page to download the latest version.

- See the tutorial on DCF - Dual Cylinder Fit

- See the tutorial on DCP - Diameter Cut Planes

- See VTube-LASER Cut Planes

- See How to Measure Tubes Attached to an Evaporator with the DCP Feature