Difference between revisions of "VTube-LASER v2.5"

(→25px MAJOR NEW FEATURE: Bend Profile Real Radius Calculation) |

(→25px NEW: BEFORE and AFTER TRIM Lengths Grid - Before The Actual Trim) |

||

| Line 141: | Line 141: | ||

</td> | </td> | ||

<td width=300> | <td width=300> | ||

| − | [[image:vtube-laser_v2.5_aftertrim_length_graphic.png| | + | [[image:vtube-laser_v2.5_aftertrim_length_graphic.png|800px]] |

<br><br> | <br><br> | ||

</td> | </td> | ||

| Line 149: | Line 149: | ||

</table> | </table> | ||

| + | |||

==[[image:Check.jpg|25px]] NEW: Communications with AIM Wire Benders== | ==[[image:Check.jpg|25px]] NEW: Communications with AIM Wire Benders== | ||

<table cellpadding=10> | <table cellpadding=10> | ||

Revision as of 16:42, 19 May 2016

Revision 2.5

|

MAJOR NEW FEATURE: Bend Profile Out-of-round % Measurement

MAJOR NEW FEATURE: Bend Profile Out-of-round % Measurement

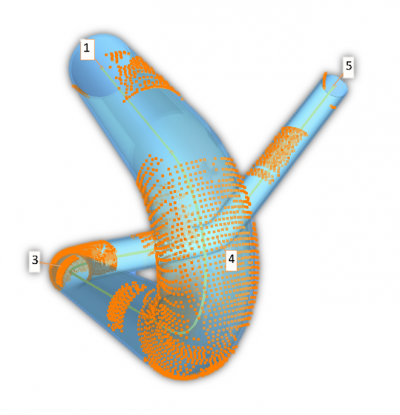

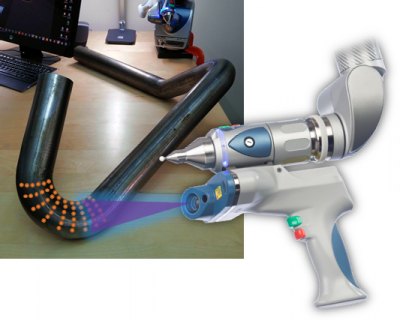

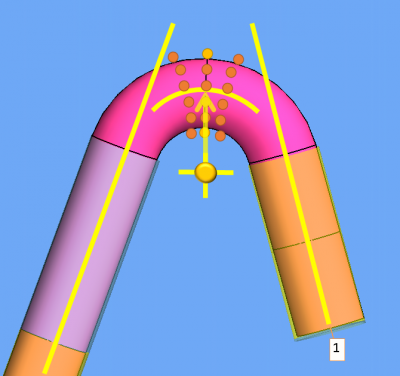

This feature is unique to FARO systems using VTube-LASER.VTube-LASER can now measure bend profile regions in order to calculate the out-of-round percentage in multiple slice regions of any bend. This feature is only possible because the FARO ScanArm uses a surface scanner to collect surface points. (Other measuring methods that do not scan surface points cannot perform this kind of measurement.) |

|

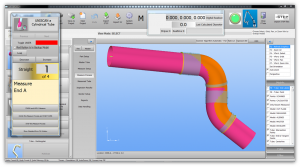

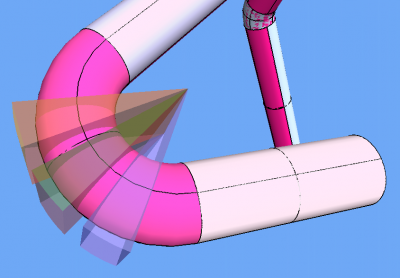

Bend Profile Measure ControlThe Bend Profile measure control can be used in the middle of the Uniscan measure.During a Uniscan tube measurement, you choose if you want to measure a bend's profile region. To save time, VTube-LASER allows you to skip measuring the profile of non-critical bends. |

|

About the Bend Profile "Slice" MetaphorThe metaphor "slice" is used to visualize the regions like slices of cake in the bend sections. |

|

Bend Profile Out-of-round GridSLICE COLUMN |

|

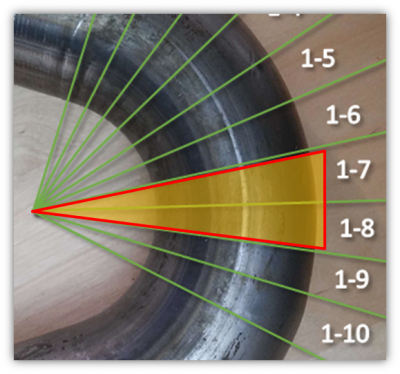

Example High OOR% = 10.5In the image on the right, you can see slices 5 through 10 in our mandrel bent Horn Demo tube. |

|

VTube-LASER Demo Tube 3 OOR% = 17 to 20This is a closeup image of the bend in demo tube 3 that the FARO account managers carry with them. |

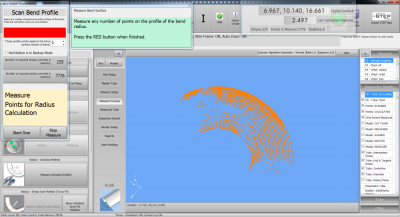

NEW: Bend Profile Radius Calculation

NEW: Bend Profile Radius Calculation

|

The Bend Profile measure feature also automatically calculates the centerline arc from the cloud data scanned around the bend. |

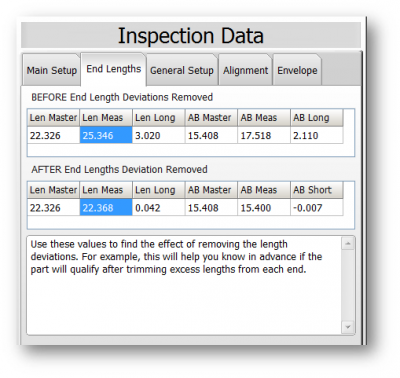

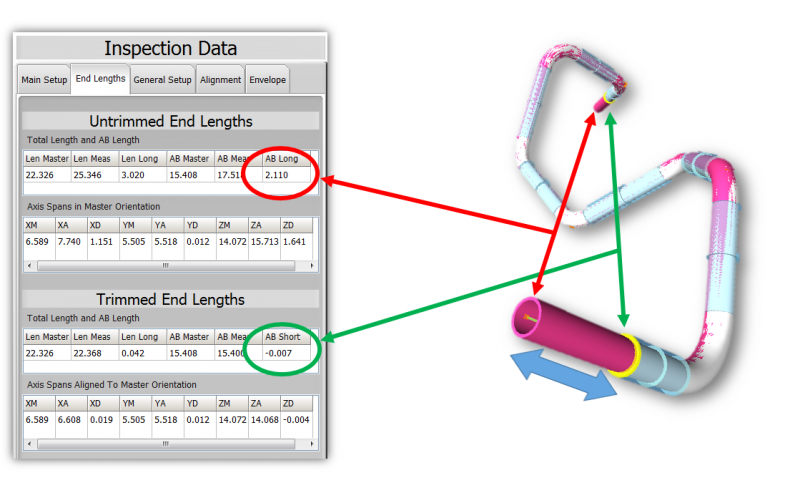

NEW: BEFORE and AFTER TRIM Lengths Grid - Before The Actual Trim

NEW: BEFORE and AFTER TRIM Lengths Grid - Before The Actual Trim

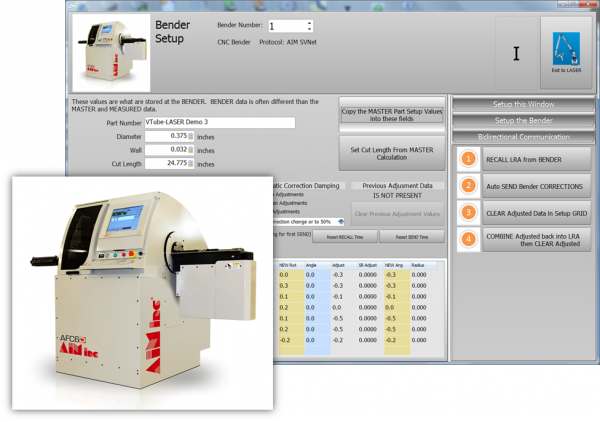

NEW: Communications with AIM Wire Benders

NEW: Communications with AIM Wire Benders

|

VTube-LASER and AIM wire benders can now communicate using the Supravision Network protocol. |

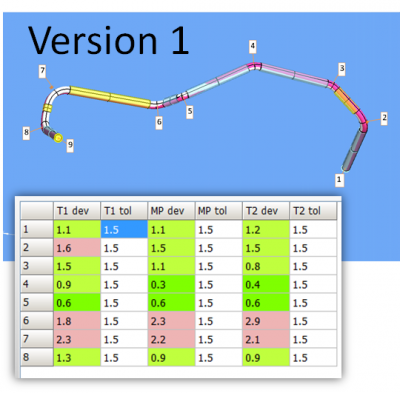

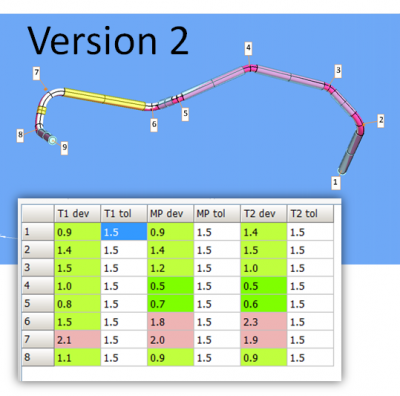

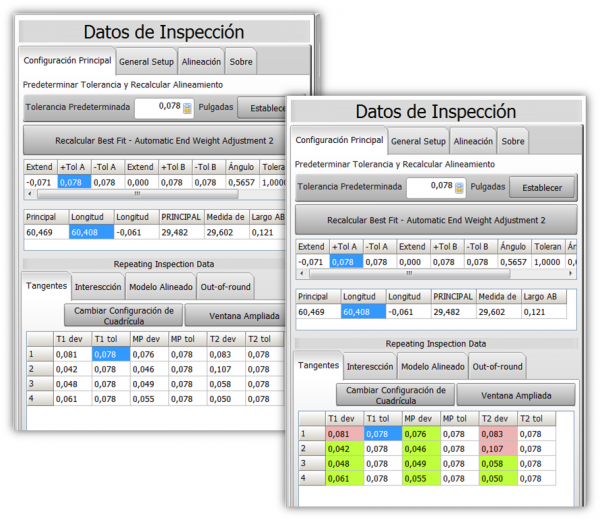

IMPROVED: Best Fit - Automatic End Weight Version 2 - Tighter and Faster Alignments

IMPROVED: Best Fit - Automatic End Weight Version 2 - Tighter and Faster Alignments

|

We're always happy to give you a feature that does more - and does more FASTER than before. This is one of those features. The alignments shown on the right are the results of the two different kinds of alignments now available in version 2.5. We used the same master/measured data. When qualifications are on the edge of the tolerance, then the new version 2 of Best Fit has a better chance of qualifying a tube.

|

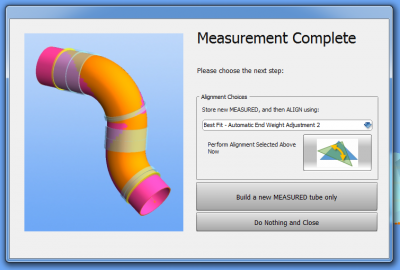

IMPROVED: The MEASUREMENT COMPLETE Window is Redesigned for Simplicity

IMPROVED: The MEASUREMENT COMPLETE Window is Redesigned for Simplicity

|

The Measurement Complete window is the window that displays when you finish measurements. It has been redesigned to make it even easier to use. |

FIX: Floating Point Numbers with Commas

FIX: Floating Point Numbers with Commas

|

Previous versions of VTube had difficulty handling number systems that uses commas as a decimal symbol. |

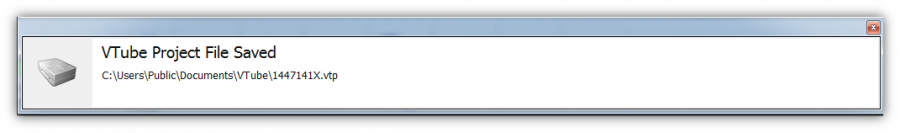

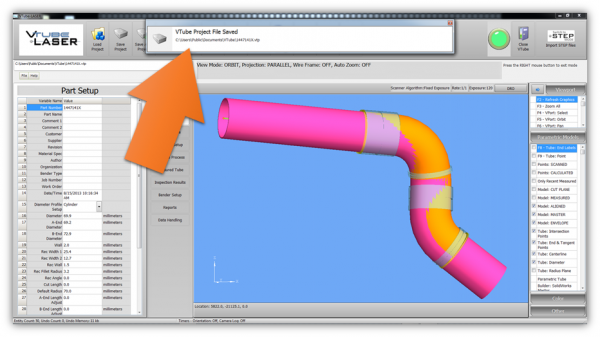

NEW: Project File Save Notification Proves the Project Was Saved

NEW: Project File Save Notification Proves the Project Was Saved

|

Previous versions of VTube were quiet when you saved a project file. That made some of our customers understandably nervous. |

NEW: HOT Keys Control-L (Load) and Control-S (Save) for VTube Project Files

NEW: HOT Keys Control-L (Load) and Control-S (Save) for VTube Project Files

|

These new hotkeys are a simple thing- but they'll make your life much easier if you're a hotkey user. (The new project save notification window described above will display every time you press CTRL-S.) |

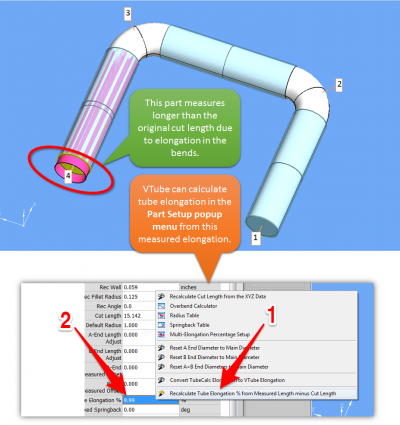

NEW: CALCULATE TUBE ELONGATION PERCENTAGE FEATURE

NEW: CALCULATE TUBE ELONGATION PERCENTAGE FEATURE

|

Now VTube-LASER can calculate Tube Elongation Percentage by subtracting the current CUT LENGTH from the MEASURED LENGTH - then calculate the percentage by comparing that change to the total ARC LENGTHS in the measured tube. |

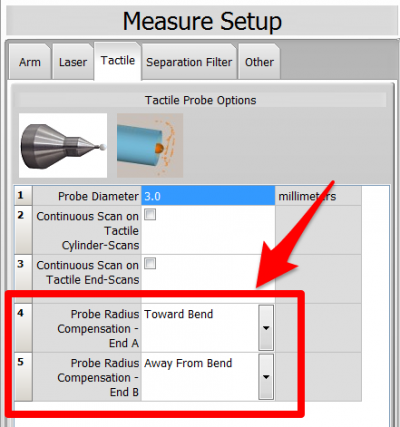

ENHANCEMENT and FIX: The PROBE RADIUS COMPENSATION Feature

ENHANCEMENT and FIX: The PROBE RADIUS COMPENSATION Feature

|

If you measure the ends of tubes with the ball probe, and the probe radius compensation directions at either end are ever different, then this update is critical for you. CHANGED CAPTIONS IN SETUP |

FIX: Transfluid XYZ Output (BKT File) Repairs

FIX: Transfluid XYZ Output (BKT File) Repairs

|

This feature allows you to output new XYZ data to the bender from inside VTube-STEP (which is part of VTube-LASER). |

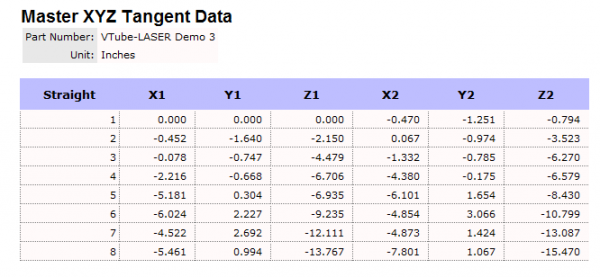

NEW: Tangent Point Reports

NEW: Tangent Point Reports

|

VTube can now output Tangent Point reports. |

NEW: Huntington Ingalls Data Import

NEW: Huntington Ingalls Data Import

|

VTube can now import Huntington Ingalls data for shipbuilding applications. |

OTHER CHANGES

OTHER CHANGES

- When decreasing the point count in VTube-LASER without clearing the project, the reports would continue to show the previous expanded point count for the Tangent Points and Midpoints list. This has been fixed.

- The Overbend Calculator incorrectly swapped the Proportional and Fixed values in the springback formula for the springback grid inside the calculator. This has been fixed.

- The Springback compensation, when enabled, was not calculated correctly in outgoing Supravision files. This has been fixed.

- The End B Length Adjustment feature would not draw the tube diameter correctly when set to more than or less than 0. This has been fixed.

- The default straight tolerance value is now used to automatically fill in tolerance fields in the grids with tolerances. (Previous versions would always use 0.039" or 1 mm for the tolerances in inspection grids.)

Other Pages

- Back to VTube-STEP

- Back to VTube Software Updates (for LASER Mode)

- Back to VTube-LASER

- See VTube Language Editor