VTube-LASER to Eaton Leonard Premier Communications Tutorial

|

VTube-LASER uses the legacy Eaton Leonard Current Loop protocol to communicate with Premier controls. The protocol requires that an RS-232 signal be converted to Current Loop, then sent to the bender. |

Contents |

How to Use Communication Between the Premier and VTube-LASER

Communications between VTube-LASER and the Premier is very easy to do because it's robust and also very intuitive.

The Initial Premier VECTOR 1 Menu

|

All communications from the PREMIER control occurs in the VECTOR 1 screen shown here. |

Premier VECTOR 1 Menu With Communications Active

|

To put the Premier in communications mode, make the REQUEST TRANSFER box active (green) like is shown here. The WAITING field will be highlighted. CHECK 1 - CORRECT MODE IS ACTIVE |

Handles all the Eaton Leonard Data in Transfers

YBC Velocity, Function, Stop, and C Last IncludedThis data includes all the part setup data and all the data that is included in each YBC row, including these data columns:

YBC Data Automatically Synchronized with Blue Column LRA Data in the Parent WindowThe YBC data in this Eaton Leonard Setup window is always synchronized with the blue columns in the parent VTube Bender Setup window. Use Either Inches or MillimetersThe screen allows you to switch between Inches and Millimeters and back again with the press of a single button.

|

SENDING from VTube-LASER to the PREMIER

|

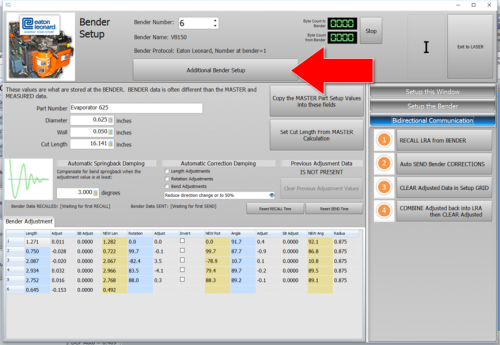

Before sending data to a legacy Eaton Leonard control, you can completely setup the control inside VTube-LASER if you have VTube-LASER version 2.7 or greater. VTube-LASER will allow for the complete setup of all bender and setup data that can be stored in a Premier, EL2000, or Velog control. The Eaton Leonard values are never lost because this data is now stored inside each VTube-LASER project file. Press the new "Additional Bender Data" button at the top of the Bender Setup screen, and VTube will now load the new Eaton Leonard Setup window.. For SENDING...

PRINCIPLE 1 - VTube-LASER Data OVERWRITES When SENDING to the PREMIER |

Other Pages

- See VTube-LASER to Premier, EL2000, Velog Data Transfer

- Back to the Benderlink Ethernet Module Page

- Back to VTube-LASER

- Back to Eaton Leonard