VTube-LASER at FABTECH

|

Tradeshow: FABTECH

|

Back to VTube-LASER

About the FABTECH Trade Show

|

Every year we exhibit at FABTECH in the tube and pipe section of the show. The show alternates between cities:

|

UNISON LTD. REAL-TIME BENDER CORRECTIONS

|

In the 2018 show, we were directly across from the UNISON LTD. booth - and were connected to their 25mm electric bender. |

How to SEND CORRECTION Data to the HERBER Control from VTube-LASER

How to SEND CORRECTION Data to the HERBER Control from VTube-LASER

STEP 1 - Bend the Tube

|

Bend the tube in the HERBER bender. |

STEP 2 - Measure the tube with VTube-LASER

|

Measure and align the tube to determine if it qualifies by falling within the envelope tolerance for the tube shape. |

STEP 3 - Enter BENDER SETUP

|

Click on the BENDER SETUP button in the Navigation Pane. |

STEP 4 - Choose the BENDER NUMBER

|

Set the correct bender number at the top of the window. |

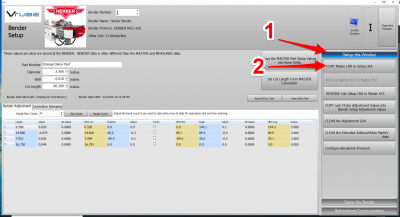

STEP 5 - COPY the Data from VTube-LASER's Main Memory

|

If this is the first correction, then the Bender Setup screen may show no data. If this is the case, then it is necessary to update the Bender Setup screen from VTube-LASER's main memory like this:

|

STEP 6 - OPTIONAL STEP - You Can Manually Change the ADJUSTMENT Values

|

You can manually change the ADJUSTMENT values before sending corrections if you want to. Some users like to set the first and last Length adjustment to zero in order to keep the start position of the carriage in the same place - for when they have extra length on the ends. |

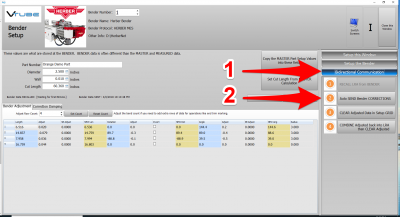

STEP 7 - Send Corrections to the HERBER

|

Press "Auto SEND Bender CORRECTIONS". VTube-LASER will let you select a path, then save a MES file to that path. |

STEP 8 - The SEND to BENDER Complete Window

|

A window should appear for a few seconds indicating that the Send to the Bender is complete. |

STEP 9 - IMPORT the Correction Data at the HERBER Control

|

Move to the HERBER control and follow these steps:

|

|

|

|

|

STEP 10 - REPEAT STEPS 1 THROUGH 9

|

Bend the corrected tube starting in Step 1, then measure it again (Step 2) and follow the rest of the steps until the part is within tolerance. |

Other Pages

- See VTube-LASER

- See VTube-STEP

- See UNISON for information on UNISON benders