VTube-LASER Cylinder Fit Tolerances

|

"How Well Does Centerline Fit the Cylinder Surface Points?"

|

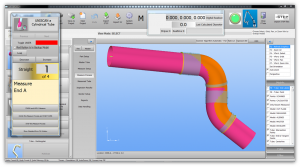

VTube-LASER uses surface points scanned with laser or measured with ball probes to calculate tube centerlines. |

The Cylinder Fit Data Window Reports How Well the Centerline Fits the Surface Data

|

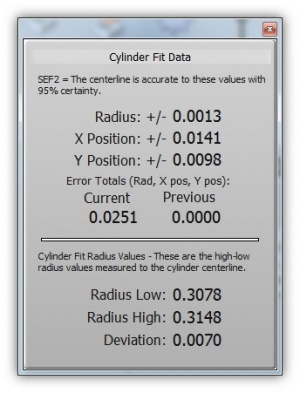

After calculating a cylinder centerline from surface points, VTube-LASER reports how well the centerline FITS the surface points of the cylinder. These values are shown in the Cylinder Fit Data window.

These estimate values are calculated using statistical math. The values are standard deviation x 2, which means that we have 95% assurance that the these values are the maximum deviation. |

Wobble Deviation - The highest of the X or Y values

|

To simplify visualizing the X and Y Position deviation, we say that the highest of the X and Y values is the "wobble deviation". The wobble deviation in the example on the right is 0.21 inches - because this is the higher of the two values. |

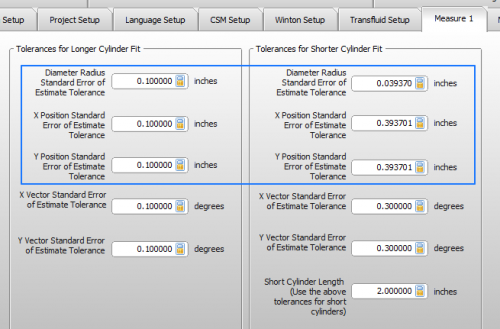

Default Cylinder Fit Tolerances

|

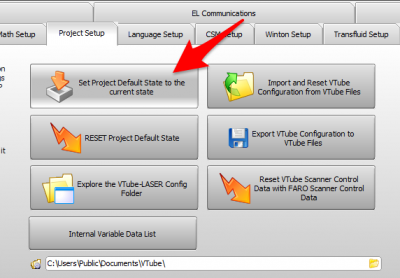

To allow VTube-LASER to warn for poor cylinder measurements, it stores tolerances for the allowed deviations during cylinder fit. These values are often setup in the Measure 1 tab of the System Options menu. |

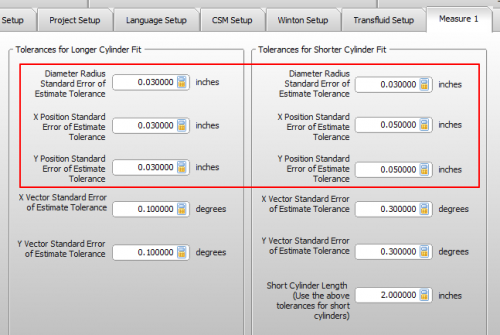

Recommended Aerospace Cylinder Fit Tolerances

|

Aerospace-grade materials are often very precise. For aerospace applications, we strongly recommend that you consider using tighter tolerances like these shown here. |

How to Test for Your Ideal Tolerances

|

You can test for ideal cylinder fit tolerance settings by watching the tolerance values in the Cylinder Fit window when measuring a tube. |

Other Pages

- Back to VTube-LASER

- Back to VTube-STEP