Difference between revisions of "Recommendations for FARO Arms"

(→Arm Repeatability and Ball Probe Accuracy) |

(→FARO ES Scanner) |

||

| (43 intermediate revisions by one user not shown) | |||

| Line 6: | Line 6: | ||

This chart shows the arm repeatability for the different FARO arm models. FARO arm sizes is listed in VOLUME - which means the diameter of the sphere volume that the arm can reach in total. So the length of the arm 1/2 the volume value. | This chart shows the arm repeatability for the different FARO arm models. FARO arm sizes is listed in VOLUME - which means the diameter of the sphere volume that the arm can reach in total. So the length of the arm 1/2 the volume value. | ||

| − | <table width="100%" cellspacing="0" cellpadding="5" border="0" align="left"> <tr style="padding-top: 5px; padding-bottom: 5px;"> <th align="left"> </th> <th align="left" style="border-bottom-width: 1px; border-bottom-style: solid; border-bottom-color: #cccccc;" colspan="6"> <div style="text-align: center;"><strong style="color: #0055a0;" class="AA_pgS">WORKING VOLUME</strong></div> </th> </tr> <tr style="padding-top: 5px; padding-bottom: 5px; border-bottom-width: 1px; border-bottom-style: solid; border-bottom-color: #f2f2f2;"> <th width="80" align="left" style="border-right-width: 1px; border-right-style: solid; border-right-color: #cccccc;"><br /> </th> <th width="80" align="left" style="border-bottom-width: 1px; border-bottom-style: solid; border-bottom-color: #cccccc;"><span class="AA_pgS" style="color: #0055a0;">1.2 M (4 foot)</span></th> <th width="80" align="left" style="border-bottom-width: 1px; border-bottom-style: solid; border-bottom-color: #cccccc;"><span class="AA_pgS" style="color: #0055a0;">1.8 M (6 foot)</span></th> <th width="80" align="left" style="border-bottom-width: 1px; border-bottom-style: solid; border-bottom-color: #cccccc;"><span class="AA_pgS" style="color: #0055a0;">2.4 M (8 foot)</span></th> <th width="80" align="left" style="border-bottom-width: 1px; border-bottom-style: solid; border-bottom-color: #cccccc;"><span class="AA_pgS" style="color: #0055a0;">2.7 M (9 foot)</span></th> <th width="80" align="left" style="border-bottom-width: 1px; border-bottom-style: solid; border-bottom-color: #cccccc;"><span class="AA_pgS" style="color: #0055a0;">3 M (10 foot)</span></th> <th width="80" align="left" style="border-bottom-width: 1px; border-bottom-style: solid; border-bottom-color: #cccccc; border-right-width: 1px; border-right-style: solid; border-right-color: #cccccc;"><span class="AA_pgS" style="color: #0055a0;">3.7 M (12 foot)</span></th> </tr> <tr style="padding-top: 5px; padding-bottom: 5px; border-bottom-width: 1px; border-bottom-style: solid; border-bottom-color: #f2f2f2; background-color: #e9f4f9;"> <th align="left" style="text-align: left; border-right-width: 1px; border-right-style: solid; border-right-color: #cccccc;" class="accuracy"> <div style="color: #0055a0;">Edge</div> </th> <td align="left"> </td> <td align="left">0.024 (0.00094)</td> <td align="left"> </td> <td align="left">0.029 (0.0010) </td> <td align="left"> </td> <td align="left" style="border-right-width: 1px; border-right-style: solid; border-right-color: #cccccc;">0.064 (0.0025)</td> </tr> <tr style="padding-top: 5px; padding-bottom: 5px; border-bottom-width: 1px; border-bottom-style: solid; border-bottom-color: #f2f2f2;"> <th align="left" style="text-align: left; border-right-width: 1px; border-right-style: solid; border-right-color: #cccccc;" class="accuracy"> <div style="color: #0055a0;">Prime</div> </th> <td align="left">0.016 (0.0006)</td> <td align="left">0.019 (0.00075)</td> <td align="left">0.024 (0.00094)</td> <td align="left"> </td> <td align="left">0.042 (0.0017)</td> <td align="left" style="border-right-width: 1px; border-right-style: solid; border-right-color: #cccccc;">0.060 (0.0023)</td> </tr> <tr style="padding-top: 5px; padding-bottom: 5px; border-bottom-width: 1px; border-bottom-style: solid; border-bottom-color: #f2f2f2; background-color: #e9f4f9;"> <th align="left" style="text-align: left; border-right-width: 1px; border-right-style: solid; border-right-color: #cccccc;"> <div style="color: #0055a0;">Fusion</div> </th> <td align="left"> </td> <td align="left">0.036 (0.0014)</td> <td align="left">0.043 (0.0017)</td> <td align="left"> </td> <td align="left">0.074 (0.0029)</td> <td align="left" style="border-right-width: 1px; border-right-style: solid; border-right-color: #cccccc;">0.104 (0.0040) </td> </tr> <tr> <th align="left" style="text-align: left;"> </th> <td align="left" colspan="6" style="border-top-width: 1px; border-top-style: solid; border-top-color: #cccccc;"><span style="text-align: left; margin-top: 5px; color: #0055a0;" class="AA_pgS"><strong>REPEATABILITY mm (in)</strong></span><br /> <br /> <em><span class="small">Performance specifications according to B89.4.22 </span></em></td> </tr> | + | <table width="100%" cellspacing="0" cellpadding="5" border="0" align="left"> <tr style="padding-top: 5px; padding-bottom: 5px;"> <th align="left"> </th> <th align="left" style="border-bottom-width: 1px; border-bottom-style: solid; border-bottom-color: #cccccc;" colspan="6"> <div style="text-align: center;"><strong style="color: #0055a0;" class="AA_pgS">WORKING VOLUME</strong></div> </th> </tr> <tr style="padding-top: 5px; padding-bottom: 5px; border-bottom-width: 1px; border-bottom-style: solid; border-bottom-color: #f2f2f2;"> <th width="80" align="left" style="border-right-width: 1px; border-right-style: solid; border-right-color: #cccccc;"><br /> </th> <th width="80" align="left" style="border-bottom-width: 1px; border-bottom-style: solid; border-bottom-color: #cccccc;"><span class="AA_pgS" style="color: #0055a0;">1.2 M (4 foot)</span></th> <th width="80" align="left" style="border-bottom-width: 1px; border-bottom-style: solid; border-bottom-color: #cccccc;"><span class="AA_pgS" style="color: #0055a0;">1.8 M (6 foot)</span></th> <th width="80" align="left" style="border-bottom-width: 1px; border-bottom-style: solid; border-bottom-color: #cccccc;"><span class="AA_pgS" style="color: #0055a0;">2.4 M (8 foot)</span></th> <th width="80" align="left" style="border-bottom-width: 1px; border-bottom-style: solid; border-bottom-color: #cccccc;"><span class="AA_pgS" style="color: #0055a0;">2.7 M (9 foot)</span></th> <th width="80" align="left" style="border-bottom-width: 1px; border-bottom-style: solid; border-bottom-color: #cccccc;"><span class="AA_pgS" style="color: #0055a0;">3 M (10 foot)</span></th> <th width="80" align="left" style="border-bottom-width: 1px; border-bottom-style: solid; border-bottom-color: #cccccc; border-right-width: 1px; border-right-style: solid; border-right-color: #cccccc;"><span class="AA_pgS" style="color: #0055a0;">3.7 M (12 foot)</span></th> </tr> <tr style="padding-top: 5px; padding-bottom: 5px; border-bottom-width: 1px; border-bottom-style: solid; border-bottom-color: #f2f2f2; background-color: #e9f4f9;"> <th align="left" style="text-align: left; border-right-width: 1px; border-right-style: solid; border-right-color: #cccccc;" class="accuracy"> <div style="color: #0055a0;">Edge</div> </th> <td align="left"> </td> <td align="left">0.024 (0.00094)</td> <td align="left"> </td> <td align="left">0.029 (0.0010) </td> <td align="left"> </td> <td align="left" style="border-right-width: 1px; border-right-style: solid; border-right-color: #cccccc;">0.064 (0.0025)</td> </tr> <tr style="padding-top: 5px; padding-bottom: 5px; border-bottom-width: 1px; border-bottom-style: solid; border-bottom-color: #f2f2f2;"> <th align="left" style="text-align: left; border-right-width: 1px; border-right-style: solid; border-right-color: #cccccc;" class="accuracy"> <div style="color: #0055a0;">Prime</div> </th> <td align="left">0.016 (0.0006)</td> <td align="left">0.019 (0.00075)</td> <td align="left">0.024 (0.00094)</td> <td align="left"> </td> <td align="left">0.042 (0.0017)</td> <td align="left" style="border-right-width: 1px; border-right-style: solid; border-right-color: #cccccc;">0.060 (0.0023)</td> </tr> <tr style="padding-top: 5px; padding-bottom: 5px; border-bottom-width: 1px; border-bottom-style: solid; border-bottom-color: #f2f2f2; background-color: #e9f4f9;"> <th align="left" style="text-align: left; border-right-width: 1px; border-right-style: solid; border-right-color: #cccccc;"> <div style="color: #0055a0;">Fusion</div> </th> <td align="left"> </td> <td align="left">0.036 (0.0014)</td> <td align="left">0.043 (0.0017)</td> <td align="left"> </td> <td align="left">0.074 (0.0029)</td> <td align="left" style="border-right-width: 1px; border-right-style: solid; border-right-color: #cccccc;">0.104 (0.0040) </td> </tr> <tr> <th align="left" style="text-align: left;"> </th> <td align="left" colspan="6" style="border-top-width: 1px; border-top-style: solid; border-top-color: #cccccc;"><span style="text-align: left; margin-top: 5px; color: #0055a0;" class="AA_pgS"><strong>REPEATABILITY mm (in)</strong></span><br /> <br /> <em><span class="small">Performance specifications according to B89.4.22 </span></em></td> </tr></table> |

| − | </table> | + | |

| + | These repeatability values are also referred to by FARO account managers as "accuracy" values. | ||

===Ball Probe Accuracy=== | ===Ball Probe Accuracy=== | ||

| − | + | You can expect the ball probes to perform close to the values listed in the grid above when the arm is setup and used properly. | |

===Laser Line Probe Accuracy=== | ===Laser Line Probe Accuracy=== | ||

| Line 19: | Line 20: | ||

<tr> | <tr> | ||

<td> | <td> | ||

| − | The HD scanner is the blue laser scanner. It is also known as "Version 6" internally at FARO. | + | * The HD scanner is the blue laser scanner. It is also known as "Version 6" internally at FARO. |

| − | |||

| − | + | * It is, by far, the best performing laser scanner that FARO offers. If you can afford this scanner, '''then we STRONGLY recommend it over every other scanner.''' | |

| − | For details on why, see this page about the scanner: [[FARO Version 6 Scanner]] | + | |

| + | * The reason is because it handles reflectivity issues MUCH better than all previous versions. (Black surfaces and mirror-finish surfaces scan less accurately than other finish surfaces. However, unlike older scanners, it can still scan these surfaces without using surface coatings.) | ||

| + | |||

| + | |||

| + | * If you were to point the laser at a wall with the grip pointing toward the floor, then you will see a vertical laser line on the wall. The effect is to give the sensation that you are spray-painting the surface with the laser with a left to right or right to left motion relative to the handle. | ||

| + | |||

| + | |||

| + | * For details on why, see this page about the scanner: [[FARO Version 6 Scanner]] | ||

</td> | </td> | ||

| Line 35: | Line 42: | ||

</tr> | </tr> | ||

</table> | </table> | ||

| + | <br><br> | ||

==FARO ES Scanner== | ==FARO ES Scanner== | ||

| Line 40: | Line 48: | ||

<tr> | <tr> | ||

<td> | <td> | ||

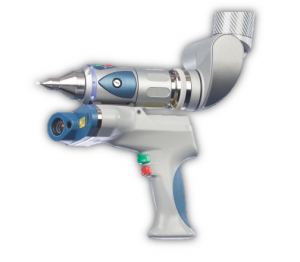

| − | The ES scanner is the last red laser scanner released. It is also known as "Version 5" internally at FARO. | + | * The ES scanner is the last red laser scanner released. It is also known as "Version 5" internally at FARO. |

| − | |||

| − | It | + | * It's performance is much better than any previous versions, but (unlike the HD scanner) you may have to deal with lighting issues with this scanner. Sometimes external lighting can interfere with this scanner. You may need to move the arm to a darker room to measure. Skylights from external sunlight will probably make scanning impossible in our experience. |

| − | If you must purchase an non HD scanner, this the only other scanner that we recommend. | + | |

| + | * It is often necessary to run this scanner in FIXED exposure mode - rather than AUTO. This is a bit of an inconvenience to the customer. But customers don't seem to mind anyway. | ||

| + | |||

| + | |||

| + | * It also cannot handle reflectivity issues as well as the HD scanner. The way to solve this issue is to spray the part with a surface coating that is a white or a bright color (yellow, blue, green, red, etc.). | ||

| + | |||

| + | |||

| + | * If you were to point the laser at a wall with the grip pointing toward the floor, then you will see a vertical laser line on the wall. The effect is to give the sensation that you are spray-painting the surface with the laser with a left to right or right to left motion relative to the handle. | ||

| + | |||

| + | |||

| + | * If you must purchase an non HD scanner, this the only other scanner that we recommend. | ||

</td> | </td> | ||

<td> | <td> | ||

| + | |||

| + | <br><br> | ||

[[image:FARO_LLP_v5.png|300px]] | [[image:FARO_LLP_v5.png|300px]] | ||

</td> | </td> | ||

| Line 57: | Line 76: | ||

</table> | </table> | ||

| + | |||

| + | <br><br> | ||

==FARO Version 4 Scanner== | ==FARO Version 4 Scanner== | ||

| Line 62: | Line 83: | ||

<tr> | <tr> | ||

<td> | <td> | ||

| − | This is the original Edge scanner. We only recommend it if this is your only option. | + | * This is the original Edge scanner. We only recommend it if this is your only option. |

| + | |||

| + | |||

| + | * This was the first scanner from FARO to have a vertical laser line. If you were to point the laser at a wall with the grip pointing toward the floor, then you will see a vertical laser line on the wall. The effect is to give the sensation that you are spray-painting the surface with the laser with a left to right or right to left motion relative to the handle. | ||

| + | |||

| + | |||

| + | |||

| + | * '''This scanner works best with the scanner exposure algorithm set to FIXED MODE. Automatic modes will not work well when measuring tube shapes.''' | ||

| + | |||

</td> | </td> | ||

| Line 71: | Line 100: | ||

</tr> | </tr> | ||

</table> | </table> | ||

| − | |||

==FARO Version 3 Scanner== | ==FARO Version 3 Scanner== | ||

| Line 77: | Line 105: | ||

<tr> | <tr> | ||

<td> | <td> | ||

| − | This scanner will not work on the Edge arm. We only recommend it if this is your only option. | + | * This scanner will not work on the Edge arm. We only recommend it if this is your only option. |

| + | |||

| + | |||

| + | * Unlike the Edge scanners, the laser line runs horizontally. So, if you were to point the laser at a wall with the grip pointing toward the floor, then you will see a horizontal laser line on the wall. | ||

| + | |||

| + | |||

| + | * '''This scanner only works with the scanner exposure algorithm set to FIXED MODE. Automatic modes will not work well when measuring tube shapes.''' | ||

</td> | </td> | ||

| Line 86: | Line 120: | ||

</tr> | </tr> | ||

</table> | </table> | ||

| − | |||

==FARO Version 2 Scanner== | ==FARO Version 2 Scanner== | ||

| Line 92: | Line 125: | ||

<tr> | <tr> | ||

<td> | <td> | ||

| − | |||

| − | + | * This scanner does not work with Edge arms. | |

| + | |||

| + | |||

| + | * This is the oldest scanner that we know about. (We've never seen version 1.) A few customers use it in applications that don't require a lot of accuracy. It works - but it cannot be run well in a room with standard factory lighting. Also, expect to surface-coat (see [[Surface Spray]]) any slightly reflective tubes. | ||

| + | |||

| + | |||

| + | * Unlike the Edge scanners, the laser line runs horizontally. So, if you were to point the laser at a wall with the grip pointing toward the floor, then you will see a horizontal laser line on the wall. | ||

| + | |||

| + | |||

| + | * '''This scanner only works with the scanner exposure algorithm set to FIXED MODE. Automatic modes will not work well when measuring tube shapes.''' | ||

| + | |||

| + | |||

| + | </td> | ||

<td> | <td> | ||

| Line 105: | Line 149: | ||

==Other Pages== | ==Other Pages== | ||

| − | See [[VTube-LASER]] | + | * See [[VTube-LASER]] |

| − | See [[FARO Version 6 Scanner]] | + | * See [[FARO Version 6 Scanner]] |

| + | * See [[Surface Spray]] | ||

Latest revision as of 16:52, 10 May 2018

This page answers questions about which FARO arm to use in your tube measuring application. We've listed the different options in this page so that you know what to consider.

Contents |

Arm Repeatability and Ball Probe Accuracy

This chart shows the arm repeatability for the different FARO arm models. FARO arm sizes is listed in VOLUME - which means the diameter of the sphere volume that the arm can reach in total. So the length of the arm 1/2 the volume value.

| WORKING VOLUME | ||||||

|---|---|---|---|---|---|---|

| 1.2 M (4 foot) | 1.8 M (6 foot) | 2.4 M (8 foot) | 2.7 M (9 foot) | 3 M (10 foot) | 3.7 M (12 foot) | |

| Edge | 0.024 (0.00094) | 0.029 (0.0010) | 0.064 (0.0025) | |||

| Prime | 0.016 (0.0006) | 0.019 (0.00075) | 0.024 (0.00094) | 0.042 (0.0017) | 0.060 (0.0023) | |

| Fusion | 0.036 (0.0014) | 0.043 (0.0017) | 0.074 (0.0029) | 0.104 (0.0040) | ||

| REPEATABILITY mm (in) Performance specifications according to B89.4.22 | ||||||

These repeatability values are also referred to by FARO account managers as "accuracy" values.

Ball Probe Accuracy

You can expect the ball probes to perform close to the values listed in the grid above when the arm is setup and used properly.

Laser Line Probe Accuracy

In general, you can take these values are double them to get the expected accuracy of the laser scanners. FARO also calls these scanners "Laser Line Probes" because they scan using one line or "stripe" of laser at a time. The different scanners have a huge variance in performance. Choosing the right scanner is very important. (More important than choosing the right arm in our opinion.)

FARO HD Scanner

|

FARO ES Scanner

|

FARO Version 4 Scanner

|

FARO Version 3 Scanner

|

FARO Version 2 Scanner

|

Other Pages

- See VTube-LASER

- See FARO Version 6 Scanner

- See Surface Spray