Difference between revisions of "Model-based Definition"

(→VTube-STEP and VTube-LASER) |

(→MDB Solid Model Import Method - TIME REQUIRED: 30 SECONDS) |

||

| (78 intermediate revisions by one user not shown) | |||

| Line 1: | Line 1: | ||

| + | __NOTOC__ | ||

| + | |||

==What is Model-based Definition?== | ==What is Model-based Definition?== | ||

| − | According to Wikipedia: "Model-based definition (MBD), sometimes digital product definition, is the practice of using 3D models (such as solid models, 3D PMI and associated metadata) within 3D CAD software to define (provide specifications for) individual components and product assemblies." | + | According to Wikipedia: "Model-based definition (MBD), sometimes digital product definition, is the practice of using 3D models (such as solid models, 3D PMI and associated metadata) within 3D CAD software to define (provide specifications for) individual components and product assemblies."<br><br> |

| − | + | ==[[VTube-STEP]] and [[VTube-LASER]] ENABLE Model-based Definition for Tube Fabricators== | |

| − | + | [[image:vtube-step_import_table_tube_model_2.png|500px|right]] | |

| − | + | An important feature in all versions of VTube is the ability to import generic solid models of tube shapes in the STEP or IGES formats and '''then calculate and derive all of the following''':<br><br> | |

| − | + | ||

| − | ==[[VTube-STEP]] and [[VTube-LASER]]== | + | |

| − | An important feature in all versions of VTube is the ability to import generic solid models of tube shapes in the STEP or IGES formats and then calculate:<br><br> | + | |

# Part Number (based on the incoming filename)<br> | # Part Number (based on the incoming filename)<br> | ||

| Line 18: | Line 17: | ||

# Cut Length<br><br><br> | # Cut Length<br><br><br> | ||

| − | ==Benefits== | + | ==What Are The Benefits of Model-based Definition?== |

| + | <br> | ||

The benefits of MBD are significant: | The benefits of MBD are significant: | ||

# '''ELIMINATES KEYBOARD REENTRY'''<br>Creating bender data from a solid model '''eliminates keyboard entry of centerline data for the nominal or master part'''. This is a huge benefit considering many mistakes are made due to misreading or mistyping of numbers from one data grid to the next.<br><br> | # '''ELIMINATES KEYBOARD REENTRY'''<br>Creating bender data from a solid model '''eliminates keyboard entry of centerline data for the nominal or master part'''. This is a huge benefit considering many mistakes are made due to misreading or mistyping of numbers from one data grid to the next.<br><br> | ||

| − | # '''FASTER THAN KEYBOARD ENTRY'''<br> | + | # '''3 TIMES FASTER THAN KEYBOARD ENTRY in VTube'''<br>Importing data from a solid model tube is 3 times (or more) faster than keyboard entry - even if the keyboard entry is perfect the first time.<br><br> |

| − | # '''VISUAL | + | # '''VISUAL CROSS-CHECK'''<br>Model-based definition gives instant visual feedback and confirmation that the part is correct - because the derived parametric model is '''superimposed on top of the imported model on the same screen'''.<br><br> |

| + | <br><br> | ||

| + | |||

| + | ==Compare TRADITIONAL KEYBOARD INPUT and MBD IMPORT Methods== | ||

| + | |||

| + | To demonstrate the speed difference, we will use this tube shape:<br><br> | ||

| + | |||

| + | [[image:tube_tube_model.png|600px]]<br><br> | ||

| + | |||

| + | |||

| + | ===Traditional Keyboard Entry Method - TIME REQUIRED: 1 Minute 33 Seconds=== | ||

| + | In traditional data entry, the coordinate data is manually entered by typing the numerical data from a print or layout in this format: <br> | ||

| + | |||

| + | <table border="1" cellspacing="0" cellpadding="0" width="80%"> | ||

| + | <tr> | ||

| + | <td class="c0" nowrap="nowrap">Point</td> | ||

| + | <td class="c0" nowrap="nowrap">X</td> | ||

| + | <td class="c0" nowrap="nowrap">Y</td> | ||

| + | <td class="c0" nowrap="nowrap">Z</td> | ||

| + | <td class="c0" nowrap="nowrap">Radius</td> | ||

| + | </tr> | ||

| + | <tr> | ||

| + | <td class="c1" nowrap="nowrap">1</td> | ||

| + | <td class="c1" nowrap="nowrap">0.0</td> | ||

| + | <td class="c1" nowrap="nowrap">0.0</td> | ||

| + | <td class="c1" nowrap="nowrap">-800.0</td> | ||

| + | <td class="c1" nowrap="nowrap">0.0</td> | ||

| + | </tr> | ||

| + | <tr> | ||

| + | <td class="c1" nowrap="nowrap">2</td> | ||

| + | <td class="c1" nowrap="nowrap">800.0</td> | ||

| + | <td class="c1" nowrap="nowrap">0.0</td> | ||

| + | <td class="c1" nowrap="nowrap">-800.0</td> | ||

| + | <td class="c1" nowrap="nowrap">150.0</td> | ||

| + | </tr> | ||

| + | <tr> | ||

| + | <td class="c1" nowrap="nowrap">3</td> | ||

| + | <td class="c1" nowrap="nowrap">800.0</td> | ||

| + | <td class="c1" nowrap="nowrap">0.0</td> | ||

| + | <td class="c1" nowrap="nowrap">0.0</td> | ||

| + | <td class="c1" nowrap="nowrap">150.0</td> | ||

| + | </tr> | ||

| + | <tr> | ||

| + | <td class="c1" nowrap="nowrap">4</td> | ||

| + | <td class="c1" nowrap="nowrap">0.0</td> | ||

| + | <td class="c1" nowrap="nowrap">0.0</td> | ||

| + | <td class="c1" nowrap="nowrap">0.0</td> | ||

| + | <td class="c1" nowrap="nowrap">150.0</td> | ||

| + | </tr> | ||

| + | <tr> | ||

| + | <td class="c1" nowrap="nowrap">5</td> | ||

| + | <td class="c1" nowrap="nowrap">800.0</td> | ||

| + | <td class="c1" nowrap="nowrap">400.0</td> | ||

| + | <td class="c1" nowrap="nowrap">-800.0</td> | ||

| + | <td class="c1" nowrap="nowrap">150.0</td> | ||

| + | </tr> | ||

| + | <tr> | ||

| + | <td class="c1" nowrap="nowrap">6</td> | ||

| + | <td class="c1" nowrap="nowrap">0.0</td> | ||

| + | <td class="c1" nowrap="nowrap">400.0</td> | ||

| + | <td class="c1" nowrap="nowrap">-800.0</td> | ||

| + | <td class="c1" nowrap="nowrap">150.0</td> | ||

| + | </tr> | ||

| + | <tr> | ||

| + | <td class="c1" nowrap="nowrap">7</td> | ||

| + | <td class="c1" nowrap="nowrap">0.0</td> | ||

| + | <td class="c1" nowrap="nowrap">400.0</td> | ||

| + | <td class="c1" nowrap="nowrap">0.0</td> | ||

| + | <td class="c1" nowrap="nowrap">150.0</td> | ||

| + | </tr> | ||

| + | <tr> | ||

| + | <td class="c1" nowrap="nowrap">8</td> | ||

| + | <td class="c1" nowrap="nowrap">800.0</td> | ||

| + | <td class="c1" nowrap="nowrap">400.0</td> | ||

| + | <td class="c1" nowrap="nowrap">0.0</td> | ||

| + | <td class="c1" nowrap="nowrap">0.0</td> | ||

| + | </tr> | ||

| + | </table> | ||

| + | <br> | ||

| + | The time required to enter the data by a VTube expert, including the coordinates above, part name, diameter, wall thickness, and default radius is 1 minute 33 seconds.<br><br> | ||

| + | Operators who are familiar with data entry like this will recognize that this pace is very fast ''for keyboard entry''. Since this part is so simple, the time recorded DOES NOT INCLUDE DOUBLE-CHECKING THE COORDINATES. OTHER PARTS WITH THE SAME COORDINATE COUNT COULD EASILY REQUIRE MORE TIME because they would require a double-check of the values input to the original print.<br><br> | ||

| + | If the original print has no XYZ centerline grid (uses regular linear dimensions), then keyboard entry is MUCH SLOWER than what was recorded here. | ||

| + | <br><br><br> | ||

| + | |||

| + | ===MDB Solid Model Import Method - TIME REQUIRED: 30 SECONDS=== | ||

| + | <br> | ||

| + | The MBD method is significantly faster, and '''enhances data integrity''' while importing data faster. This is the result of an import in VTube for the same part. (The model also includes the table top.) | ||

| + | |||

| + | <br><br> | ||

| + | |||

| + | [[image:vtube-step_table_tube_import.png|600px]]<br> | ||

| + | |||

| + | The time required to open the file, load the file, completely import the data by a VTube expert, and to derive all the data entered above automatically, is only 30 seconds. | ||

| + | <br><br> | ||

| + | |||

| + | # '''CENTERLINE COORDINATES:''' VTube was able to calculate the centerline coordinates from the straight sections selected.<br><br> | ||

| + | # '''RADIUS:''' VTube was able to calculate the radius values because the straights are built from tangent point to tangent point (where the straights meet the bends).<br><br> | ||

| + | # '''DIAMETER:''' VTube was able to calculate the diameter from the largest cylinder selected.<br><br> | ||

| + | # '''WALL THICKNESS:''' VTube was able to find the wall thickness because we also selected the inner wall of straight 7 (see the end at point 8 in the image above).<br><br> | ||

| + | # '''PART NUMBER:''' The part number is filled in using the incoming filename with the path removed.<br><br> | ||

| + | # '''CUT LENGTH:''' The cut length is automatically calculated during import.<br><br> | ||

| + | |||

| + | ==Other Pages== | ||

| + | |||

| + | * See [[VTube-STEP]] | ||

| + | * See [[VTube-LASER]] | ||

| + | * See the [https://en.wikipedia.org/wiki/Model-based_definition Wikipedia page] for Model-based Definition | ||

Latest revision as of 01:29, 14 August 2015

What is Model-based Definition?

According to Wikipedia: "Model-based definition (MBD), sometimes digital product definition, is the practice of using 3D models (such as solid models, 3D PMI and associated metadata) within 3D CAD software to define (provide specifications for) individual components and product assemblies."

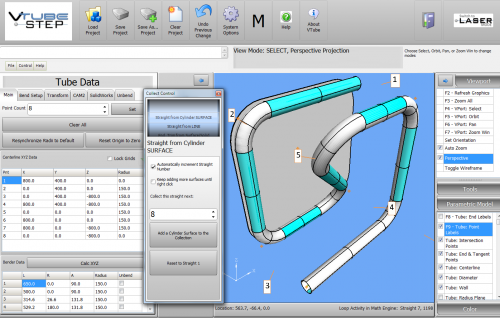

VTube-STEP and VTube-LASER ENABLE Model-based Definition for Tube Fabricators

An important feature in all versions of VTube is the ability to import generic solid models of tube shapes in the STEP or IGES formats and then calculate and derive all of the following:

- Part Number (based on the incoming filename)

- XYZ centerline

- Radius values for every bend

- Diameter

- Wall thickness

- Bender data

- Cut Length

What Are The Benefits of Model-based Definition?

The benefits of MBD are significant:

- ELIMINATES KEYBOARD REENTRY

Creating bender data from a solid model eliminates keyboard entry of centerline data for the nominal or master part. This is a huge benefit considering many mistakes are made due to misreading or mistyping of numbers from one data grid to the next.

- 3 TIMES FASTER THAN KEYBOARD ENTRY in VTube

Importing data from a solid model tube is 3 times (or more) faster than keyboard entry - even if the keyboard entry is perfect the first time.

- VISUAL CROSS-CHECK

Model-based definition gives instant visual feedback and confirmation that the part is correct - because the derived parametric model is superimposed on top of the imported model on the same screen.

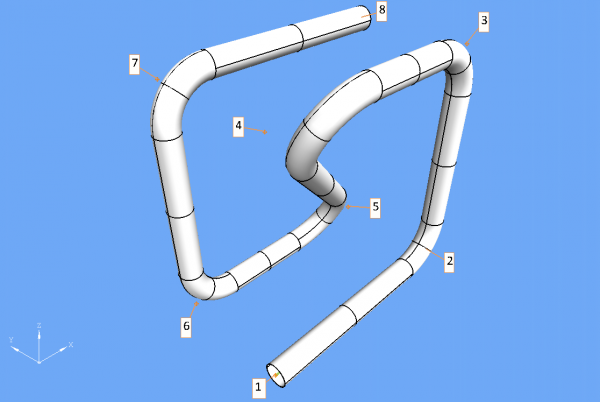

Compare TRADITIONAL KEYBOARD INPUT and MBD IMPORT Methods

To demonstrate the speed difference, we will use this tube shape:

Traditional Keyboard Entry Method - TIME REQUIRED: 1 Minute 33 Seconds

In traditional data entry, the coordinate data is manually entered by typing the numerical data from a print or layout in this format:

| Point | X | Y | Z | Radius |

| 1 | 0.0 | 0.0 | -800.0 | 0.0 |

| 2 | 800.0 | 0.0 | -800.0 | 150.0 |

| 3 | 800.0 | 0.0 | 0.0 | 150.0 |

| 4 | 0.0 | 0.0 | 0.0 | 150.0 |

| 5 | 800.0 | 400.0 | -800.0 | 150.0 |

| 6 | 0.0 | 400.0 | -800.0 | 150.0 |

| 7 | 0.0 | 400.0 | 0.0 | 150.0 |

| 8 | 800.0 | 400.0 | 0.0 | 0.0 |

The time required to enter the data by a VTube expert, including the coordinates above, part name, diameter, wall thickness, and default radius is 1 minute 33 seconds.

Operators who are familiar with data entry like this will recognize that this pace is very fast for keyboard entry. Since this part is so simple, the time recorded DOES NOT INCLUDE DOUBLE-CHECKING THE COORDINATES. OTHER PARTS WITH THE SAME COORDINATE COUNT COULD EASILY REQUIRE MORE TIME because they would require a double-check of the values input to the original print.

If the original print has no XYZ centerline grid (uses regular linear dimensions), then keyboard entry is MUCH SLOWER than what was recorded here.

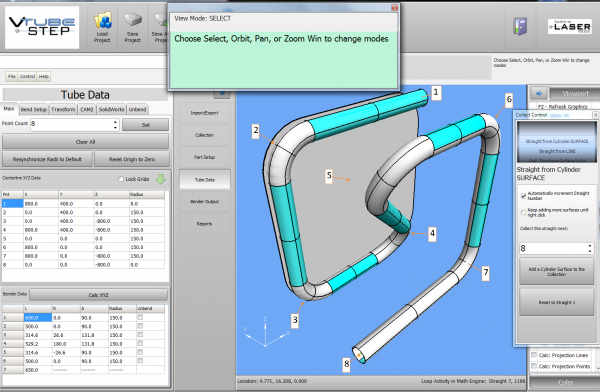

MDB Solid Model Import Method - TIME REQUIRED: 30 SECONDS

The MBD method is significantly faster, and enhances data integrity while importing data faster. This is the result of an import in VTube for the same part. (The model also includes the table top.)

The time required to open the file, load the file, completely import the data by a VTube expert, and to derive all the data entered above automatically, is only 30 seconds.

- CENTERLINE COORDINATES: VTube was able to calculate the centerline coordinates from the straight sections selected.

- RADIUS: VTube was able to calculate the radius values because the straights are built from tangent point to tangent point (where the straights meet the bends).

- DIAMETER: VTube was able to calculate the diameter from the largest cylinder selected.

- WALL THICKNESS: VTube was able to find the wall thickness because we also selected the inner wall of straight 7 (see the end at point 8 in the image above).

- PART NUMBER: The part number is filled in using the incoming filename with the path removed.

- CUT LENGTH: The cut length is automatically calculated during import.

Other Pages

- See VTube-STEP

- See VTube-LASER

- See the Wikipedia page for Model-based Definition