Difference between revisions of "Measuring Coping"

(→Idea: Design a Coping Adapter in a Solid Modelling Program) |

|||

| (17 intermediate revisions by one user not shown) | |||

| Line 2: | Line 2: | ||

<tr cellpadding=10> | <tr cellpadding=10> | ||

<td width=225> | <td width=225> | ||

| + | [[image:vtube-step_logo_1.96.png|200px]] | ||

[[image:vtube-laser_logo_1.96.png|200px]] | [[image:vtube-laser_logo_1.96.png|200px]] | ||

| + | * Back to [[VTube-STEP]] | ||

* Back to [[VTube-LASER]] | * Back to [[VTube-LASER]] | ||

</td> | </td> | ||

| Line 14: | Line 16: | ||

__NOTOC__ | __NOTOC__ | ||

| − | |||

| − | |||

| + | This article discusses how to measure a coping along with the tube shape in VTube-LASER. The method used is to measure the coping as if it were an additional straight on the end of the tube.<br><br> | ||

| + | In order to do this, an adapter pipe that joins the main pipe at the coping can be treated like and extra end-straight on the pipe in VTube-LASER | ||

| − | == | + | |

| + | == STEP 1: Design a Coping Adapter in a Solid Modelling Program== | ||

<table width=800> | <table width=800> | ||

| Line 38: | Line 41: | ||

<br> | <br> | ||

| − | == Import | + | == STEP 2: Import the Model with the Adapter into VTube-STEP== |

<table> | <table> | ||

| Line 44: | Line 47: | ||

<tr valign=top> | <tr valign=top> | ||

<td width=300> | <td width=300> | ||

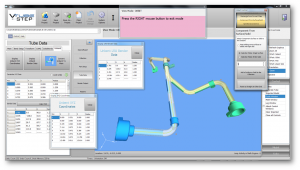

| − | + | VTube-STEP is included as one of the modes with every VTube-LASER. Switch to STEP mode, then clear the project, then import the STEP model created in the solid modelling program.<br><br> | |

| − | + | ||

</td> | </td> | ||

<td> | <td> | ||

| − | [[image:vtube-step_v2. | + | [[image:vtube-step_v2.3_import_coping_adapter_part.png|600px]] |

</td> | </td> | ||

</tr> | </tr> | ||

| Line 56: | Line 58: | ||

| − | == | + | == STEP 3: Collect the Surfaces with the Adapter in VTube-STEP== |

<table> | <table> | ||

| Line 62: | Line 64: | ||

<tr valign=top> | <tr valign=top> | ||

<td width=300> | <td width=300> | ||

| − | + | Use the Collect feature to build a collection of cylinder surfaces. Include the adapter as the end straight.<br><br> | |

| − | + | ||

| − | + | ||

| − | + | ||

</td> | </td> | ||

<td> | <td> | ||

| − | [[image: | + | [[image:vtube-step_v2.3_collect_coping_adapter_part.png|600px]] |

</td> | </td> | ||

</tr> | </tr> | ||

<tr> | <tr> | ||

| + | </table> | ||

| + | <br> | ||

| + | |||

| + | == STEP 4: Rebuild the Model in VTube-STEP== | ||

| + | |||

| + | <table> | ||

| + | |||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | Right click and rebuild the model.<br><br> | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:vtube-step_v2.3_rebuild_coping_adapter_part.png|600px]] | ||

| + | </td> | ||

| + | </tr> | ||

| + | <tr> | ||

| + | </table> | ||

| + | <br> | ||

| + | |||

| + | |||

| + | == STEP 5: Confirm the Parametric Model in VTube-STEP== | ||

| + | |||

| + | <table> | ||

| + | |||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | You can now confirm the new parametric model (the model that is controlled by new XYZ coordinates) by pressing F9 to turn on and view the point labels.<br><br> | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:vtube-step_v2.3_pointlabels_coping_adapter_part.png|600px]] | ||

| + | </td> | ||

| + | </tr> | ||

| + | <tr> | ||

| + | </table> | ||

| + | <br> | ||

| + | |||

| + | |||

| + | == STEP 6: Switch to VTube-LASER Mode and Measure the Part== | ||

| + | |||

| + | <table> | ||

| + | |||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | Switch to VTube-LASER, attach the adapter (temporarily) to the coping on the part, then measure and qualify the entire part with the adapter.<br><br> | ||

| + | It is not a problem that there is no radius at the first intersection between the first and second straights. The measurement and qualification will still produce useful information about how to adjust the tube and the coping. | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:vtube-laser_v2.3_measure_coping_adapter_part.png|600px]] | ||

| + | </td> | ||

| + | </tr> | ||

| + | <tr> | ||

| + | </table> | ||

| + | <br> | ||

| + | |||

| + | |||

| + | == STEP 7: Setup and Align the Measured Part== | ||

| + | |||

| + | <table> | ||

| + | |||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | In this alignment, we used 321 Plane Line Point alignment to lock the tube to itself, and allow all the error to float to the coping end of the tube.<br><br> | ||

| + | The pink tube is the measured aligned tube. It allows you to visualize how far out of the envelope the coping is when the adapter is attached.<br><br> | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:vtube-laser_v2.3_align_inspect_coping_adapter_part.png|600px]]<br><br> | ||

| + | </td> | ||

| + | </tr> | ||

| + | |||

| + | </table> | ||

| + | <br> | ||

| + | |||

| + | == STEP 8: Get the Rotational Adjustment== | ||

| + | |||

| + | <table> | ||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | You can also print out a Bender Corrections Only report to see the exact rotational adjusting to make to the part when cutting the coping.</td> | ||

| + | <td> | ||

| + | [[image:vtube-laser_v2.3_report_coping_adapter_part.png|600px]]<br><br> | ||

| + | </td> | ||

| + | </tr> | ||

| + | |||

| + | |||

</table> | </table> | ||

<br> | <br> | ||

Latest revision as of 16:37, 21 March 2016

|

This article discusses how to measure a coping along with the tube shape in VTube-LASER. The method used is to measure the coping as if it were an additional straight on the end of the tube.

In order to do this, an adapter pipe that joins the main pipe at the coping can be treated like and extra end-straight on the pipe in VTube-LASER

STEP 1: Design a Coping Adapter in a Solid Modelling Program

|

In this example, we designed an adapter in SOLIDWORKS that simulates the joining pipe to the main pipe. |

|

STEP 2: Import the Model with the Adapter into VTube-STEP

|

VTube-STEP is included as one of the modes with every VTube-LASER. Switch to STEP mode, then clear the project, then import the STEP model created in the solid modelling program. |

|

STEP 3: Collect the Surfaces with the Adapter in VTube-STEP

|

Use the Collect feature to build a collection of cylinder surfaces. Include the adapter as the end straight. |

|

STEP 4: Rebuild the Model in VTube-STEP

|

Right click and rebuild the model. |

|

STEP 5: Confirm the Parametric Model in VTube-STEP

|

You can now confirm the new parametric model (the model that is controlled by new XYZ coordinates) by pressing F9 to turn on and view the point labels. |

|

STEP 6: Switch to VTube-LASER Mode and Measure the Part

|

Switch to VTube-LASER, attach the adapter (temporarily) to the coping on the part, then measure and qualify the entire part with the adapter. |

|

STEP 7: Setup and Align the Measured Part

|

In this alignment, we used 321 Plane Line Point alignment to lock the tube to itself, and allow all the error to float to the coping end of the tube. |

STEP 8: Get the Rotational Adjustment

| You can also print out a Bender Corrections Only report to see the exact rotational adjusting to make to the part when cutting the coping. |

Other Pages

- Back to the VTube-STEP page

- Back to the VTube-LASER page