Difference between revisions of "Mandrel Lube"

(→Mandrel Lube Start and Stop) |

(→Why Does the Mandrel Lube "Stop Within" Value Work This Way?) |

||

| (33 intermediate revisions by one user not shown) | |||

| Line 8: | Line 8: | ||

<tr> | <tr> | ||

<td> | <td> | ||

| − | Topic: How to Use Mandrel Lube | + | Topic:''' How to Use Mandrel Lube''' |

</td> | </td> | ||

<td> | <td> | ||

| − | Mandrel Lube is a powerful feature that is used to precisely control when the lube is injected | + | Mandrel Lube is a powerful feature that is used to precisely control when the lube is injected into the mandrel rod. |

</td> | </td> | ||

</tr> | </tr> | ||

| Line 53: | Line 53: | ||

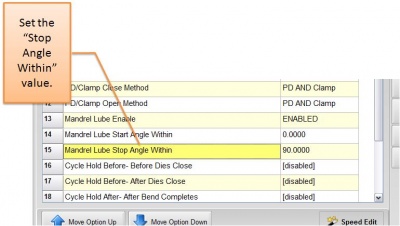

The stop angle refers to where the lube zone ends: The value is an angle that is subtracted from the FINAL ANGLE.<br> | The stop angle refers to where the lube zone ends: The value is an angle that is subtracted from the FINAL ANGLE.<br> | ||

<br> | <br> | ||

| − | For example, if you set the stop angle to 50 degrees on a 50 degree bend, then the mandrel lube '''will never start''' - because CNC Bender is told to stop the lube 50 degrees below the goal - which is 50 minus 50 | + | For example, if you set the stop angle to 50 degrees on a 50 degree bend, then the mandrel lube '''will never start''' - because CNC Bender is told to stop the lube 50 degrees below the goal - which is 50 minus 50, or 0 degrees. |

</td> | </td> | ||

<td> | <td> | ||

| Line 61: | Line 61: | ||

</tr> | </tr> | ||

</table> | </table> | ||

| + | <br><br> | ||

| + | ==Why Does the Mandrel Lube "Stop Angle Within" Value Work This Way?== | ||

| − | == | + | <table> |

| + | <tr> | ||

| + | <td width=300> | ||

| + | The "stop within" value is always relative to the final bend angle so that if the start and stop values are set to ZERO, then the operator can know for sure that the ENTIRE bend is lubricated - even when the bend angle is adjusted. | ||

| + | <br><br> | ||

| + | We believe that, after the setup technician becomes used to this standard, this makes setup easier. | ||

| + | </td> | ||

| + | <td width=300> | ||

| + | |||

| + | </td> | ||

| + | </tr> | ||

| + | </table> | ||

| + | <br><br> | ||

| + | |||

| + | ==Press [[AutoBuild]] To Make the Changes Take Effect in [[CNC Processor]]== | ||

<table> | <table> | ||

<tr> | <tr> | ||

<td width=300> | <td width=300> | ||

| − | Always press AutoBuild in the Bender Data menu for this change to take effect.</td> | + | Always press [[AutoBuild]] in the Bender Data menu for this change to take effect.</td> |

<td> | <td> | ||

| − | [[image: | + | [[image:autobuild.jpg|400px]] |

| − | [[image: | + | </td> |

| + | </tr> | ||

| + | </table> | ||

| + | |||

| + | |||

| + | ==Test Your Knowledge 1== | ||

| + | |||

| + | <table> | ||

| + | <tr> | ||

| + | <td width=300> | ||

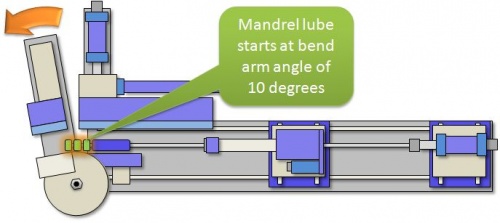

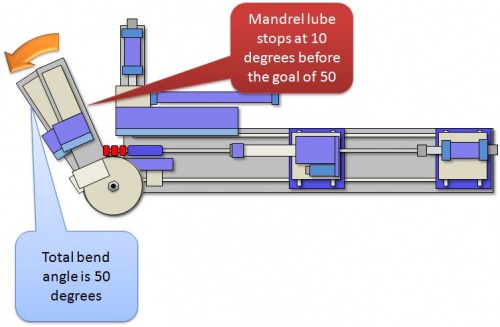

| + | If... | ||

| + | * the bend angle is 50 degrees | ||

| + | * the "start angle within" value is 10 degrees | ||

| + | * the "stop angle within" value is 10 degrees | ||

| + | <br> | ||

| + | ...how many degrees of bend will the mandrel be lubed? | ||

| + | <br><br> | ||

| + | '''Answer: 30 degrees'''<br><br> | ||

| + | Reason: The lube starts at 10 degrees and stops at 50 minus 10 degrees. So 40-10 = 30 degrees of lube. | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:mandrellube_diagram_startat10degrees.jpg|500px]]<br> | ||

| + | [[image:mandrellube_diagram_stopat10under50degrees.jpg|500px]]<br> | ||

| + | |||

| + | </td> | ||

| + | </tr> | ||

| + | </table> | ||

| + | |||

| + | ==Test Your Knowledge 2== | ||

| + | |||

| + | <table> | ||

| + | <tr> | ||

| + | <td width=300> | ||

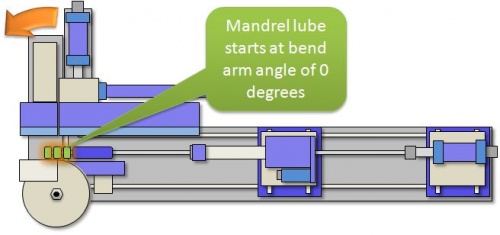

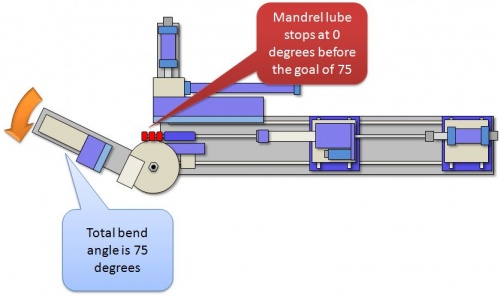

| + | If... | ||

| + | * the bend angle is 75 degrees | ||

| + | * the "start angle within" value is 0 degrees | ||

| + | * the "stop angle within" value is 0 degrees | ||

| + | <br> | ||

| + | ...how many degrees of bend will the mandrel be lubed? | ||

| + | <br><br> | ||

| + | '''Answer: 75 degrees'''<br><br> | ||

| + | Reason: The lube starts at 0 degrees and stops at 75 minus 0 degrees. So 75-0 = 75 degrees of lube. | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:mandrellube_diagram_startat0degrees.jpg|500px]]<br> | ||

| + | [[image:mandrellube_diagram_stopat75degrees.jpg|500px]]<br> | ||

| + | </td> | ||

| + | </tr> | ||

| + | </table> | ||

| + | |||

| + | ==Test Your Knowledge 3== | ||

| + | |||

| + | <table> | ||

| + | <tr> | ||

| + | <td width=300> | ||

| + | If... | ||

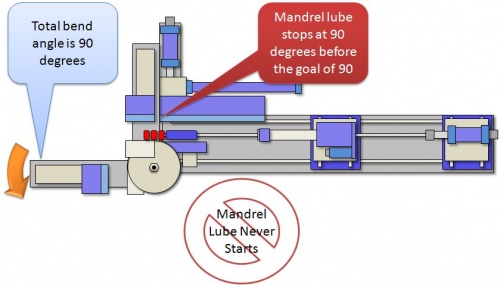

| + | * the bend angle is 90 degrees | ||

| + | * the "start angle within" value is 0 degrees | ||

| + | * the "stop angle within" value is 90 degrees | ||

| + | <br> | ||

| + | ...how many degrees of bend will the mandrel be lubed? | ||

| + | <br><br> | ||

| + | '''Answer: None'''<br><br> | ||

| + | Reason: The lube starts at 0 degrees and stops at 90 minus 90 degrees. So 0-0 = 0 degrees of lube. | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:mandrellube_diagram_neverstart90degrees.jpg|500px]] | ||

</td> | </td> | ||

</tr> | </tr> | ||

</table> | </table> | ||

Latest revision as of 14:04, 31 December 2009

|

Contents |

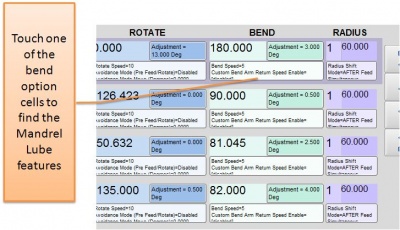

Where is the Mandrel Lube Option?

|

The lube feature is only available inside the Bend Option cells of the FRB menu. This allows an operator to control mandrel lube for each bend.

|

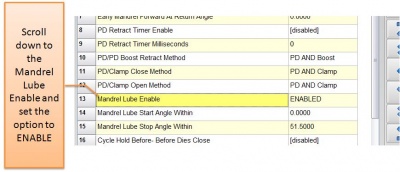

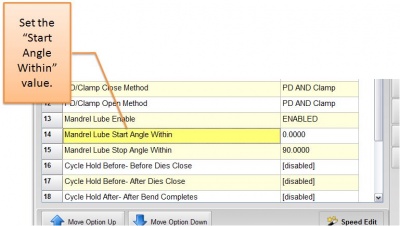

Mandrel Lube Start and Stop

|

This feature works with the Mandrel Lube Start and Mandrel Lube Stop angle settings. These control the start and stop of the mandrel lube based upon the bend angle.

|

Why Does the Mandrel Lube "Stop Angle Within" Value Work This Way?

|

The "stop within" value is always relative to the final bend angle so that if the start and stop values are set to ZERO, then the operator can know for sure that the ENTIRE bend is lubricated - even when the bend angle is adjusted.

|

Press AutoBuild To Make the Changes Take Effect in CNC Processor

| Always press AutoBuild in the Bender Data menu for this change to take effect. |

Test Your Knowledge 1

|

If...

|

Test Your Knowledge 2

|

If...

|

Test Your Knowledge 3

|

If...

|