Difference between revisions of "How To Import Channel-Shaped Parts"

(Created page with "<table> <tr cellpadding=10> <td width=225> 200px 200px * Back to VTube-STEP * Back to [[VTube-LASER]...") |

(→Offset the Legs of the Path to Get the Correct Bender Data Lengths) |

||

| (13 intermediate revisions by one user not shown) | |||

| Line 17: | Line 17: | ||

| − | == What is a Channel-Shaped Part== | + | == What is a Channel-Shaped Part?== |

<table> | <table> | ||

| Line 33: | Line 33: | ||

<br> | <br> | ||

| − | == | + | == How To Find The Bend Data== |

<table> | <table> | ||

| Line 39: | Line 39: | ||

<tr valign=top> | <tr valign=top> | ||

<td width=300> | <td width=300> | ||

| − | + | Find the bend data for this kind of part by treating the path of one of corner radii as if it were a tube shape. If you zoom in on this part's edge, you will find two radii. Choose one of them using the standard collection process for tube shapes.</td> | |

| − | + | ||

<td> | <td> | ||

| − | [[image: | + | [[image:channel-shape-corner-radius.png|400px]] |

</td> | </td> | ||

</tr> | </tr> | ||

| Line 49: | Line 48: | ||

<br> | <br> | ||

| + | == Use the Default Collection Process for Straight Cylinders== | ||

| − | == | + | <table> |

| + | |||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | Use the default straight cylinder collection process along the path of a corner radius like this. </td> | ||

| + | <td> | ||

| + | [[image:vtube-step_collect_corner_radius_path_as_tube.png|400px]] | ||

| + | </td> | ||

| + | </tr> | ||

| + | <tr> | ||

| + | </table> | ||

| + | <br> | ||

| + | |||

| + | |||

| + | == Build a Tube Centerline== | ||

<table> | <table> | ||

| Line 56: | Line 70: | ||

<tr valign=top> | <tr valign=top> | ||

<td width=300> | <td width=300> | ||

| − | You | + | Collect the corner radius for each straight just like you were collecting the cylinders in each straight. |

| − | + | ||

| + | When the collection is complete, right-click until you get a pop-up menu, then click on "Rebuild the Tube Model from Collected." | ||

| + | |||

| + | You will see a tube that is formed around the path of the corner radii selected. | ||

| + | |||

| + | At this point, the BEND ANGLES and ROTATION ANGLES are already correct. You will need to offset each leg slightly in order to get the correct LENGTHS (see below).</td> | ||

| + | <td> | ||

| + | [[image:tube-shape_in_corner_radius_path.png|400px]] | ||

| + | </td> | ||

| + | </tr> | ||

| + | <tr> | ||

| + | </table> | ||

| + | <br> | ||

| + | |||

| + | == Offset the Legs of the Path to Get the Correct Bender Data Lengths== | ||

| + | |||

| + | <table> | ||

| + | |||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | Offset the legs along the path to bring them to where you want the centerline to be. | ||

| + | |||

| + | You can calculate the offset, or just estimate it. Either way, the end result should be that the centerline matches the inner wall of the channel like in this image. | ||

| + | |||

| + | In this model, the offset was 0.030" along the Y axis for this last straight. | ||

| + | |||

| + | You will want to move the other legs of the centerline also. In this shape, points 1 and 2 were moved right along the Y axis 0.030". Points 2, 3, and 4 were moved up the Z axis 0.030", and points 4 and 5 (the final leg) were moved left along the Y axis. This brought the centerline of the tube inline with the inner wall of the channel. | ||

| + | |||

| + | </td> | ||

| + | <td> | ||

| + | [[image:channel-shape_move_legs_along_axes.png|600px]] | ||

| + | </td> | ||

| + | </tr> | ||

| + | <tr> | ||

| + | </table> | ||

| + | <br> | ||

| + | |||

| + | == The Final Centerline Follows the Channel Wall== | ||

| + | |||

| + | <table> | ||

| + | |||

| + | <tr valign=top> | ||

| + | <td width=300> | ||

| + | If the tube centerline follows the wall that you want to use as the centerline for the channel-shape, then you now have the correct LRA bender data for the channel in the Tube Data menu. | ||

| + | |||

| + | In some cases, you may need to adjust the radii to make the bend arcs follow the wall of the channel better. In this case, we just leave the radius values untouched, because they are already very close to the nominal values. | ||

| + | </td> | ||

<td> | <td> | ||

| − | [[image: | + | [[image:inner_channel-shape_bend_data.png|600px]] |

| − | + | ||

| − | + | ||

</td> | </td> | ||

</tr> | </tr> | ||

Latest revision as of 12:39, 4 October 2016

|

What is a Channel-Shaped Part?

|

This kind of part is an extrusion that is not a closed tube shape. It looks like what you see in this image. |

|

How To Find The Bend Data

| Find the bend data for this kind of part by treating the path of one of corner radii as if it were a tube shape. If you zoom in on this part's edge, you will find two radii. Choose one of them using the standard collection process for tube shapes. | |

Use the Default Collection Process for Straight Cylinders

| Use the default straight cylinder collection process along the path of a corner radius like this. | |

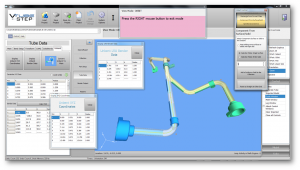

Build a Tube Centerline

|

Collect the corner radius for each straight just like you were collecting the cylinders in each straight. When the collection is complete, right-click until you get a pop-up menu, then click on "Rebuild the Tube Model from Collected." You will see a tube that is formed around the path of the corner radii selected. At this point, the BEND ANGLES and ROTATION ANGLES are already correct. You will need to offset each leg slightly in order to get the correct LENGTHS (see below). |

|

Offset the Legs of the Path to Get the Correct Bender Data Lengths

|

Offset the legs along the path to bring them to where you want the centerline to be. You can calculate the offset, or just estimate it. Either way, the end result should be that the centerline matches the inner wall of the channel like in this image. In this model, the offset was 0.030" along the Y axis for this last straight. You will want to move the other legs of the centerline also. In this shape, points 1 and 2 were moved right along the Y axis 0.030". Points 2, 3, and 4 were moved up the Z axis 0.030", and points 4 and 5 (the final leg) were moved left along the Y axis. This brought the centerline of the tube inline with the inner wall of the channel. |

|

The Final Centerline Follows the Channel Wall

|

If the tube centerline follows the wall that you want to use as the centerline for the channel-shape, then you now have the correct LRA bender data for the channel in the Tube Data menu. In some cases, you may need to adjust the radii to make the bend arcs follow the wall of the channel better. In this case, we just leave the radius values untouched, because they are already very close to the nominal values. |

|

Other Pages

- Back to the VTube-STEP page

- Back to the VTube-LASER page