D of Bend

- Back to VTube-STEP or VTube-LASER

Contents |

What is D of bend?

Tube fabricators sometimes indicate the centerline radius using D of bend.

We say it by speaking three words: "D of bend".

Some tube fabricators also say "D factor" to mean the same thing.

It is a ratio calculated like this: D of bend = Centerline Radius / OD

How Is It Used?

FABRICATORS: The D of bend value helps fabricators know if the radius is tight or large compared to the OD. It serves as a general guide for how difficult it will be to create a quality bend. It helps fabricators know what kind of tooling will be necessary to achieve the bend. It is useful, therefore, in building quotations for customers.

CUSTOMER DESIGNERS: It is also helpful for designers as a limit for what is practical.

It is common for fabricators will tell customers the lower limit for their D of bend capability.

Examples

In many applications, a lower D of bend valued radii is more esthetic. But it is harder to bend, and therefore more expensive.

- D of bend = 2.00 is generally considered not too complex.

- D of bend = 1.50 is moderately difficult.

- D of bend = 1.00 is difficult.

- D of bend = 0.75 is very difficult and much more expensive.

D of bend values at 1 and below are possible - but are rare and require special benders that can press material into the bender's dies. (Most call this "carriage boost".)

Import After Fix

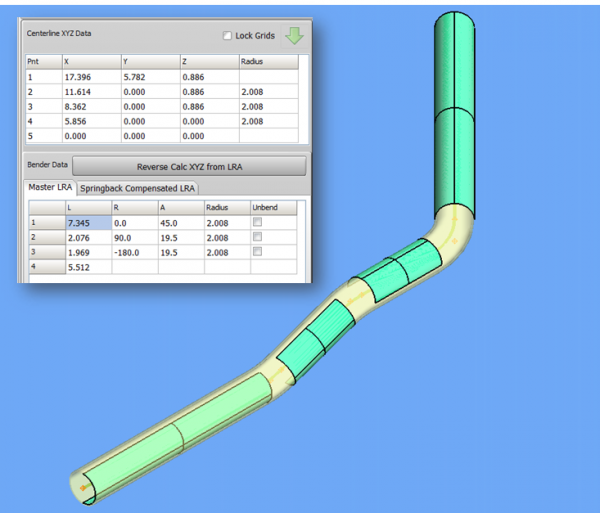

This is how the imported part shows now: