Difference between revisions of "Compare UniScan to MultiScan Measurements"

(Created page with "<table> <tr cellpadding=10> <td width=225> 300px ==Measure and Clock Tube Legs== </td> <td width=300> image:vtube-laser_v2.7_screensh...") |

(→Can UniScan and MultiScan Result In Different Numbers?) |

||

| (22 intermediate revisions by one user not shown) | |||

| Line 5: | Line 5: | ||

| − | == | + | ==Compare UniScan and MultiScan Measurements== |

| + | |||

| Line 16: | Line 17: | ||

| + | |||

| + | == VTube-LASER UniScan Measurements== | ||

<table cellpadding=10 width=900> | <table cellpadding=10 width=900> | ||

<tr valign=top> | <tr valign=top> | ||

<td width=300> | <td width=300> | ||

| − | + | VTube-LASER UniScan measurements take one group of evenly spaced laser stripes along the profile of each straight cylinder. These stripes each contain points. The method used with UniScan is similar to spray painting.<br><br> | |

| − | < | + | |

| − | < | + | ===VTube-LASER UNISCAN - The Best Way to Calculate the Centerline=== |

| − | + | UniScan is the best way to get to a true centerline average - especially for deformed diameters in straights. The reason is because UniScan averages out the entire surface of the straight measured.<br><br> | |

| − | + | And when VTube-LASER operators use wide-scanning techniques, then there is no better way to get to the truth of the centerline placement.<br><br> | |

| + | |||

| + | ===Compared to Fork Probe Method=== | ||

| + | Methods that use fork proves take very limited data on the surface (like fork probes with two crossing infrared beams. Examples are the 6-axis tube probe systems from HEXAGON. | ||

| + | |||

| + | ===Compared to Silouette Method=== | ||

| + | Methods that use tube edge are "silouette" measuring centers. Examples are like the Eaton Leonard LASERVISION and the AICON TubeInspect system. These systems only look at the edge of the diameter and cannot use that data to calculate the same data that VTube-LASER can in its Cylinder Fit window. | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

</td> | </td> | ||

<td> | <td> | ||

| − | [[image: | + | [[image:uniscan.png|500px]]<br><br> |

| + | [[image:uniscan_stripes.png|500px]]<br><br> | ||

| + | </td> | ||

| + | |||

</tr> | </tr> | ||

| + | </table> | ||

| + | <br><br> | ||

| + | |||

| + | ==MultiScan Measurements== | ||

| + | |||

| + | <table cellpadding=10 width=900> | ||

<tr valign=top> | <tr valign=top> | ||

<td width=300> | <td width=300> | ||

| − | + | MultiScan only measures near the tangents of a straight. (The tangents are the locations on the straights where the straights and bends meet.)<br><br> | |

| + | MultiScan measurements are usually reserved for straights that are bowed - like in brake lines with long straights.<br><br> | ||

| + | For those kinds of tubes it is often the case that MultiScan is the only way to solve for a centerline. (UniScan would reject those kinds of straights using its default tolerances.)</td> | ||

| + | <td> | ||

| + | [[image:multiscan.png|500px]] | ||

</td> | </td> | ||

| − | |||

| − | |||

</tr> | </tr> | ||

| − | |||

</table> | </table> | ||

Latest revision as of 22:12, 12 April 2019

|

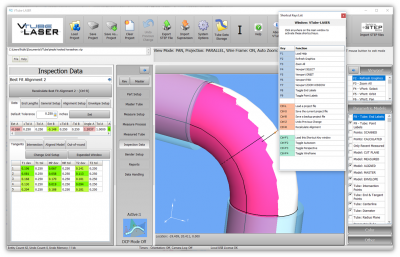

Compare UniScan and MultiScan Measurements |

VTube-LASER UniScan Measurements

|

VTube-LASER UniScan measurements take one group of evenly spaced laser stripes along the profile of each straight cylinder. These stripes each contain points. The method used with UniScan is similar to spray painting. VTube-LASER UNISCAN - The Best Way to Calculate the CenterlineUniScan is the best way to get to a true centerline average - especially for deformed diameters in straights. The reason is because UniScan averages out the entire surface of the straight measured. Compared to Fork Probe MethodMethods that use fork proves take very limited data on the surface (like fork probes with two crossing infrared beams. Examples are the 6-axis tube probe systems from HEXAGON. Compared to Silouette MethodMethods that use tube edge are "silouette" measuring centers. Examples are like the Eaton Leonard LASERVISION and the AICON TubeInspect system. These systems only look at the edge of the diameter and cannot use that data to calculate the same data that VTube-LASER can in its Cylinder Fit window.

|

MultiScan Measurements

|

MultiScan only measures near the tangents of a straight. (The tangents are the locations on the straights where the straights and bends meet.) |

Other Pages

- Back to VTube-LASER