Difference between revisions of "Compare UniScan to MultiScan Measurements"

From ATTWiki

(Created page with "<table> <tr cellpadding=10> <td width=225> 300px ==Measure and Clock Tube Legs== </td> <td width=300> image:vtube-laser_v2.7_screensh...") |

|||

| Line 5: | Line 5: | ||

| − | == | + | ==Compare UniScan and MultiScan Measurements== |

| Line 20: | Line 20: | ||

<tr valign=top> | <tr valign=top> | ||

<td width=300> | <td width=300> | ||

| − | + | UniScan measurements take one group of evening spaced points over the entire straight. The method use to measure with UniScan is like spray painting.<br><br> | |

| + | UniScan is the best way to get to a true centerline average - especially for deformed diameters in straights. The reason is because UniScan averages out the entire surface of the straight measured. | ||

</td> | </td> | ||

<td> | <td> | ||

| − | + | ||

</tr> | </tr> | ||

<tr valign=top> | <tr valign=top> | ||

<td width=300> | <td width=300> | ||

| − | + | MulitScan only measures near the tangents of a straight. (The tangents are the locations on the straights where the straights and bends meet.<br><br> | |

| − | </td> | + | MultiScan measurements are usually reserved for straights that are bowed - like in brake lines with long straights.<br><br> |

| + | For those kinds of tubes</td> | ||

<td> | <td> | ||

| − | + | ||

</tr> | </tr> | ||

Revision as of 14:08, 28 March 2018

|

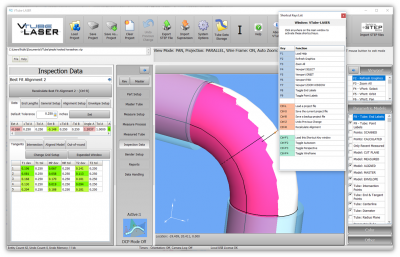

Compare UniScan and MultiScan Measurements |

|

UniScan measurements take one group of evening spaced points over the entire straight. The method use to measure with UniScan is like spray painting. |

|

|

MulitScan only measures near the tangents of a straight. (The tangents are the locations on the straights where the straights and bends meet. |

|

|

|

|

Other Pages

- Back to VTube-LASER