Difference between revisions of "CNC Bender v10-20070928"

(→Automatic FEED Torque Limit When Outside of Range) |

|||

| (37 intermediate revisions by one user not shown) | |||

| Line 6: | Line 6: | ||

=CHANGES to CNC BENDER= | =CHANGES to CNC BENDER= | ||

| − | ===Automatic FEED Torque Limit When Outside of Range=== | + | ===[[image:Check.jpg|25px]] Automatic FEED Torque Limit When Outside of Range=== |

| − | Now CNC Bender software uses the FEED torque limiting values programmed into the Low Level menu to ensure that any torque levels outside the range are automatically changed to be within valid range. This change occurs inside the Process List Builder. | + | Now CNC Bender software uses the FEED torque limiting values programmed into the Low Level menu to ensure that any FEED-BEND torque levels outside the range are automatically changed to be within valid range. This change occurs inside the Process List Builder. |

This will protect the carriage against very low or high torque values in the CNC Bender Process List. | This will protect the carriage against very low or high torque values in the CNC Bender Process List. | ||

| Line 14: | Line 14: | ||

<br><br> | <br><br> | ||

| − | ===Update to File Load User Window=== | + | |

| + | |||

| + | ===[[image:Check.jpg|25px]] Update to File Load User Window=== | ||

'''CNC Bender's FILE LOAD menu is reworked significantly''' based on customer input. | '''CNC Bender's FILE LOAD menu is reworked significantly''' based on customer input. | ||

| Line 29: | Line 31: | ||

<br><br> | <br><br> | ||

| − | ===Update to File SAVE Window=== | + | ===[[image:Check.jpg|25px]] Update to File SAVE Window=== |

CNC Bender's FILE SAVE menu is simplified. This is no more multiple path selection with Alias names. | CNC Bender's FILE SAVE menu is simplified. This is no more multiple path selection with Alias names. | ||

| Line 38: | Line 40: | ||

<br><br> | <br><br> | ||

| − | ===File System Setup Change=== | + | ===[[image:Check.jpg|25px]] Update to File DELETE Window=== |

| + | |||

| + | CNC Bender's DELETE SAVE menu is simplified. This is no more multiple path selection with Alias names. | ||

| + | |||

| + | [[image:Cncbender_filedelete.jpg|500px]] | ||

| + | |||

| + | |||

| + | <br><br> | ||

| + | |||

| + | ===[[image:Check.jpg|25px]] File System Setup Change=== | ||

| Line 52: | Line 63: | ||

[[image:Cncbender_lowlevel_pathlocation_selection.jpg|500px]] | [[image:Cncbender_lowlevel_pathlocation_selection.jpg|500px]] | ||

| + | |||

| + | |||

| + | |||

| + | <br><br> | ||

| + | |||

| + | =CHANGES to CNC PROCESSOR= | ||

| + | |||

| + | CNC Processor is the program that directly controls the bender actuators. | ||

| + | |||

| + | ===[[image:Check.jpg|25px]] Windows System-Up Timer Handler Upgrade=== | ||

| + | |||

| + | The timers in CNC Processor references the Windows system-up timer, which is a continuous millisecond counter. Previous versions of CNC Processor would generate an error after Windows had been running continuously for 24 days 20 minutes. This problem is not related to how long CNC Bender had been running, but rather, how long Windows had been running since the last reboot. | ||

| + | |||

| + | This has been repaired so that the CNC Processor will handle the Windows system-up timer value '''for any length of days'''. | ||

| + | |||

| + | <br> | ||

| + | |||

| + | ===[[image:Check.jpg|25px]] Handling Axis Motion in the NEGATIVE Region=== | ||

| + | |||

| + | It is possible for axes to settle slightly in the negative region when returning to the home position. In this condition, when sending another ABSOLUTE command for that axis to move to home again, the axis would drive in the wrong direction. For example, the bend arm would attempt to move to the absolute position of zero degrees by rotating through the bender. | ||

| + | |||

| + | As of this version, CNC Processor has been updated to examine for this condition on every axis and '''automatically reverse its direction''' if it finds that the axis is in the negative region. | ||

| + | |||

| + | <br><br> | ||

=How to UPGRADE= | =How to UPGRADE= | ||

Latest revision as of 22:44, 3 October 2007

Contents |

CHANGES to CNC BENDER

Automatic FEED Torque Limit When Outside of Range

Automatic FEED Torque Limit When Outside of Range

Now CNC Bender software uses the FEED torque limiting values programmed into the Low Level menu to ensure that any FEED-BEND torque levels outside the range are automatically changed to be within valid range. This change occurs inside the Process List Builder.

This will protect the carriage against very low or high torque values in the CNC Bender Process List.

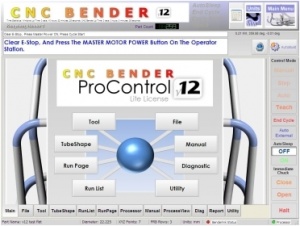

Update to File Load User Window

Update to File Load User Window

CNC Bender's FILE LOAD menu is reworked significantly based on customer input.

- There is no more multiple path selection with Alias names. This was very confusing for operators, so it has been removed.

- The menu now expands to fill the screen of an operator station.

- The menu has a new file display window that will show the information inside the selected file. This allows you to instantly view the data inside that file before loading it into memory.

- The selection of a new and custom path is much simpler.

- The custom path is considered temporary. It is only used in the current session for that window.

- The custom path feature requires a password for use.

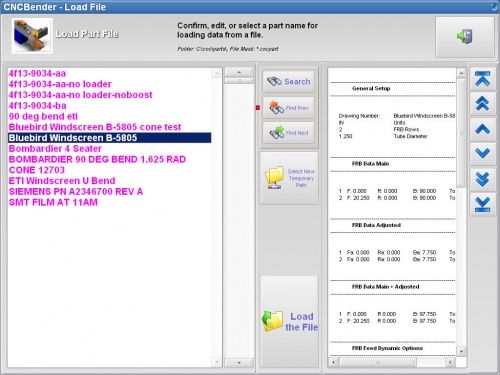

Update to File SAVE Window

Update to File SAVE Window

CNC Bender's FILE SAVE menu is simplified. This is no more multiple path selection with Alias names.

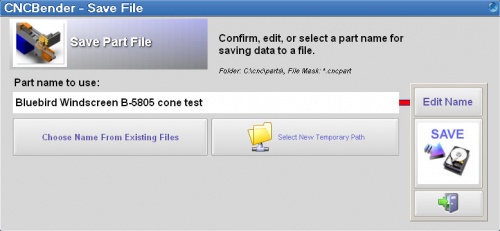

Update to File DELETE Window

Update to File DELETE Window

CNC Bender's DELETE SAVE menu is simplified. This is no more multiple path selection with Alias names.

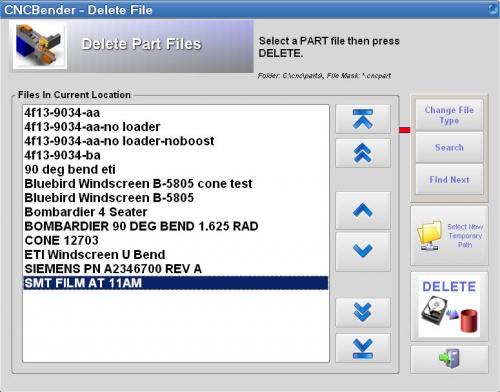

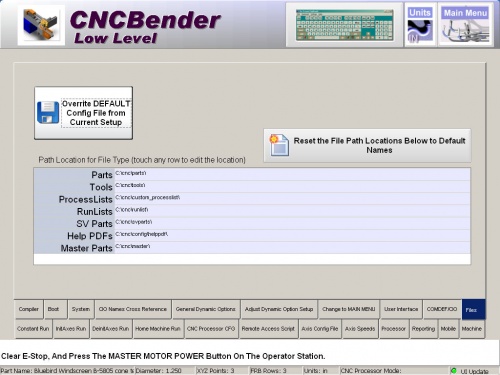

File System Setup Change

File System Setup Change

The FILE PATH SETUP has been changed significantly to make the interface simpler.

- There is a new FILE tab in the LOW LEVEL menu. Since the low level menu is protected with a password, only authorized users can gain access to where parts are found and stored on the disk or network.

- There is now a single grid that shows seven possible paths for user files like parts, tools, runlists, Supravision parts, etc.

- The path information in this setup grid is used by the main user interface when accessing different types of files.

- The paths are persistent; They are saved within the configuration file.

- Change any of the paths for any of the file types by touching that path.

- Quickly reset the default file path location pressing the "Reset..." button.

CHANGES to CNC PROCESSOR

CNC Processor is the program that directly controls the bender actuators.

Windows System-Up Timer Handler Upgrade

Windows System-Up Timer Handler Upgrade

The timers in CNC Processor references the Windows system-up timer, which is a continuous millisecond counter. Previous versions of CNC Processor would generate an error after Windows had been running continuously for 24 days 20 minutes. This problem is not related to how long CNC Bender had been running, but rather, how long Windows had been running since the last reboot.

This has been repaired so that the CNC Processor will handle the Windows system-up timer value for any length of days.

Handling Axis Motion in the NEGATIVE Region

Handling Axis Motion in the NEGATIVE Region

It is possible for axes to settle slightly in the negative region when returning to the home position. In this condition, when sending another ABSOLUTE command for that axis to move to home again, the axis would drive in the wrong direction. For example, the bend arm would attempt to move to the absolute position of zero degrees by rotating through the bender.

As of this version, CNC Processor has been updated to examine for this condition on every axis and automatically reverse its direction if it finds that the axis is in the negative region.

How to UPGRADE

If your operator station contains one of the versions listed below, then they can be upgraded through simple self-installation:

- CNC Bender v10-20070920

- CNC Bender v10-20070726b

- CNC Bender v10-20070803

- CNC Bender v10-20070828

- CNC Bender v10-20070914

Please contact Advanced Tubular Technologies for upgrade information.