Difference between revisions of "CNC Bender v10-20070920"

From ATTWiki

(→Solution To Issue) |

|||

| (33 intermediate revisions by one user not shown) | |||

| Line 1: | Line 1: | ||

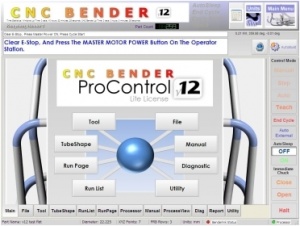

| − | [[image:Cncbender.jpg|thumb|CNC Bender User Interface for ProControl]] | + | [[image:Cncbender.jpg|300px|thumb|CNC Bender User Interface for ProControl]] |

| − | + | [[image:cncbender_logo.jpg|400px]] | |

__TOC__ | __TOC__ | ||

| − | |||

| − | + | =NEW FEATURE: Improved and Safer SOFTWARE Shutdown= | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | |||

| + | ===Explanation=== | ||

<ul> | <ul> | ||

| − | |||

| − | * CNC Bender software saves its current state and setup in a configuration files and registry entries | + | * CNC Bender software saves its current state and setup in a configuration files and registry entries during shutdown. |

| − | * If the standard shutdown procedure is bypassed due to a loss of power or a system crash, then CNC Bender, in previous versions, may attempt to write | + | * If the standard shutdown procedure is bypassed due to a loss of power or a system crash, then CNC Bender, in previous versions, may attempt to write data - ''only to be interrupted in the shutdown task''. |

| − | * The result is a possible corruption of this file.<br><br> | + | * The result is a possible corruption of this file. If the file is corrupted, then the configuration for that bender will be lost and must be recovered using one of couple methods of recovery.<br><br> |

| + | </ul> | ||

| − | ==Solution To Issue== | + | ===Solution To Issue=== |

| + | <ul> | ||

| + | |||

| + | |||

| + | This version solves '''avoids the possible corruption of data''' by placing an intentional delay between the time the operator requests a shutdown and the time the configuration data is either written to disk or written to the registry. | ||

| + | <br><br> | ||

| + | The delay message looks like this. It contains a progress bar that fills over about a 10 second period. | ||

| + | <br><br> | ||

[[image:Cncbender_shutdown_delay.jpg|500px]] | [[image:Cncbender_shutdown_delay.jpg|500px]] | ||

<br><br> | <br><br> | ||

| − | |||

| − | + | ====During a Regular Shutdown==== | |

# The operator requests shutdown of software. | # The operator requests shutdown of software. | ||

| Line 37: | Line 39: | ||

# After the progress bar is filled, CNC Bender saves its configuration data. | # After the progress bar is filled, CNC Bender saves its configuration data. | ||

| + | <br> | ||

| + | ====During an Immediate Power Loss Shutdown==== | ||

| − | + | # A loss of power to the operator station occurs. | |

| + | # CNC Bender is not given time to perform a normal shutdown because the delay progress will not be filled. | ||

| + | # CNC Bender will shutdown before it attempts to save a partial file and potentially corrupts the configuration data. | ||

| + | </ul> | ||

| + | <br><br> | ||

| − | + | =How to UPGRADE= | |

| − | + | ||

| − | + | If your operator station contains one of the versions listed below, then they can be upgraded through simple self-installation: | |

| − | [ | + | *[[CNC Bender v10-20070726b]] |

| + | *[[CNC Bender v10-20070803]] | ||

| + | *[[CNC Bender v10-20070828]] | ||

| + | *[[CNC Bender v10-20070914]] | ||

| − | + | Please contact [[Advanced Tubular Technologies]] for upgrade information. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

Latest revision as of 23:39, 20 September 2007

Contents |

NEW FEATURE: Improved and Safer SOFTWARE Shutdown

Explanation

- CNC Bender software saves its current state and setup in a configuration files and registry entries during shutdown.

- If the standard shutdown procedure is bypassed due to a loss of power or a system crash, then CNC Bender, in previous versions, may attempt to write data - only to be interrupted in the shutdown task.

- The result is a possible corruption of this file. If the file is corrupted, then the configuration for that bender will be lost and must be recovered using one of couple methods of recovery.

Solution To Issue

-

This version solves avoids the possible corruption of data by placing an intentional delay between the time the operator requests a shutdown and the time the configuration data is either written to disk or written to the registry.

- The operator requests shutdown of software.

- CNC Bender hides the interface.

- CNC Bender displays a shutdown message on the screen showing a progress bar.

- After the progress bar is filled, CNC Bender saves its configuration data.

- A loss of power to the operator station occurs.

- CNC Bender is not given time to perform a normal shutdown because the delay progress will not be filled.

- CNC Bender will shutdown before it attempts to save a partial file and potentially corrupts the configuration data.

The delay message looks like this. It contains a progress bar that fills over about a 10 second period.

During a Regular Shutdown

During an Immediate Power Loss Shutdown

How to UPGRADE

If your operator station contains one of the versions listed below, then they can be upgraded through simple self-installation:

Please contact Advanced Tubular Technologies for upgrade information.