Model-based Definition

Contents |

What is Model-based Definition?

According to Wikipedia: "Model-based definition (MBD), sometimes digital product definition, is the practice of using 3D models (such as solid models, 3D PMI and associated metadata) within 3D CAD software to define (provide specifications for) individual components and product assemblies."

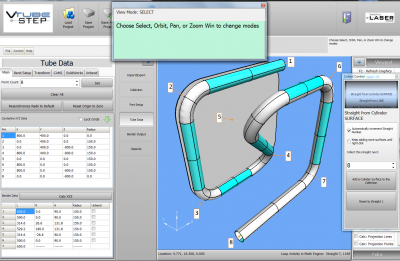

VTube-STEP and VTube-LASER

An important feature in all versions of VTube is the ability to import generic solid models of tube shapes in the STEP or IGES formats and then calculate and derive all of the following:

- Part Number (based on the incoming filename)

- XYZ centerline

- Radius values for every bend

- Diameter

- Wall thickness

- Bender data

- Cut Length

Benefits

The benefits of MBD are significant:

- ELIMINATES KEYBOARD REENTRY

Creating bender data from a solid model eliminates keyboard entry of centerline data for the nominal or master part. This is a huge benefit considering many mistakes are made due to misreading or mistyping of numbers from one data grid to the next.

- FASTER THAN KEYBOARD ENTRY

In most cases, importing data from a solid model is much faster than keyboard entry - even if the keyboard entry is perfect the first time.

- VISUAL CROSS_CHECK

Model-based Definition gives instant visual feedback and confirmation that the part is correct - because the derived parametric model is superimposed on top of the imported model on the same screen.

Compare Data Entry Methods

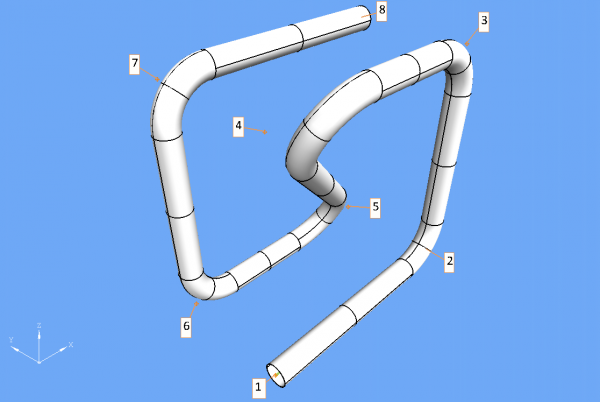

For comparison, consider this simple tube shape:

Traditional Keyboard Entry Method - TIME REQUIRED: 1 Minute 33 Seconds

In traditional data entry, the coordinate data is manually entered by copying the numerical data from a print or layout in this format:

| Point | X | Y | Z | Radius |

| 1 | 0.0 | 0.0 | -800.0 | 0.0 |

| 2 | 800.0 | 0.0 | -800.0 | 150.0 |

| 3 | 800.0 | 0.0 | 0.0 | 150.0 |

| 4 | 0.0 | 0.0 | 0.0 | 150.0 |

| 5 | 800.0 | 400.0 | -800.0 | 150.0 |

| 6 | 0.0 | 400.0 | -800.0 | 150.0 |

| 7 | 0.0 | 400.0 | 0.0 | 150.0 |

| 8 | 800.0 | 400.0 | 0.0 | 0.0 |

TIME REQUIRED: 1 minute 33 seconds

The time required to enter the data by a VTube expert, including the coordinates above, part name, diameter, wall thickness, and default radius is 1 minute 33 seconds. THIS DOES NOT INCLUDE DOUBLE CHECKING THE COORDINATES - SINCE THIS PART IS SO SIMPLE. OTHER PARTS WITH THE SAME COORDINATE COUNT WOULD REQUIRE MORE TIME.

MDB Solid Model Import Method - 30 SECONDS

The MBD method is significantly faster, and enhances data integrity at the same time it speeds the process:

TIME REQUIRED: 30 SECONDS

The time required to search for, load, and completely import the data by a VTube expert, to derive all the data entered above automatically.