Difference between revisions of "Feed Axis Faults During Feed Bending"

| Line 1: | Line 1: | ||

| − | During Feed-Bending it is possible to experience a Feed Axis Fault that is | + | During Feed-Bending it is possible to experience a Feed Axis Fault that is caused by the wrong tool radius values or an incorrect Feed Axis Adjust % value. Both are in the Tool Page. |

<br><br> | <br><br> | ||

| − | + | Quick indicators that should make you suspect that this is the case: | |

| − | + | * The Feed Axis faults especially on large angle bends | |

| − | * | + | * The Feed Axis does NOT fault when moving the bender through the cycle with no material in the machine. |

| − | * | + | |

<br><br> | <br><br> | ||

| + | ==Details== | ||

<table> | <table> | ||

<tr> | <tr> | ||

<td width="200"> | <td width="200"> | ||

| − | |||

| − | |||

The Centerline Radius values do not to match the bend die radii on the bender. | The Centerline Radius values do not to match the bend die radii on the bender. | ||

<br><br> | <br><br> | ||

| Line 27: | Line 25: | ||

<tr> | <tr> | ||

<td width="200"> | <td width="200"> | ||

| − | |||

| − | |||

The Feed Axis Adjust % Value is not set to the proper value in the Tool page. | The Feed Axis Adjust % Value is not set to the proper value in the Tool page. | ||

<br><br> | <br><br> | ||

Revision as of 20:51, 15 July 2009

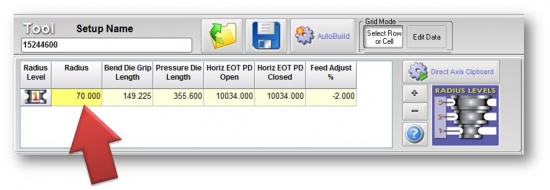

During Feed-Bending it is possible to experience a Feed Axis Fault that is caused by the wrong tool radius values or an incorrect Feed Axis Adjust % value. Both are in the Tool Page.

Quick indicators that should make you suspect that this is the case:

- The Feed Axis faults especially on large angle bends

- The Feed Axis does NOT fault when moving the bender through the cycle with no material in the machine.

Details

|

The Centerline Radius values do not to match the bend die radii on the bender.

|

|

The Feed Axis Adjust % Value is not set to the proper value in the Tool page.

That calculates to -14% elongation |