Difference between revisions of "How to Reverse Engineer with Split Bend"

(→STEP 5: Choose Build Measured Tube Data Only) |

|||

| Line 15: | Line 15: | ||

== How to Reverse Engineer A Part Using Split Bend == | == How to Reverse Engineer A Part Using Split Bend == | ||

| − | <table cellpadding=10 width=" | + | <table cellpadding=10 width="800"> |

<tr valign=top> | <tr valign=top> | ||

<td width=400 > | <td width=400 > | ||

| Line 21: | Line 21: | ||

Split Bend setup is controlled in the Bend Setup tab of the Master Tube menu in VTube-LASER, and in the Bend Setup tab in VTube-STEP. Both modes of VTube allow you to configure Split Bends.<br><br> | Split Bend setup is controlled in the Bend Setup tab of the Master Tube menu in VTube-LASER, and in the Bend Setup tab in VTube-STEP. Both modes of VTube allow you to configure Split Bends.<br><br> | ||

To turn a Split Bend ON for a straight section, you enter the Split Bend window and select the straights that should be treated as Split Bends.<br><br> | To turn a Split Bend ON for a straight section, you enter the Split Bend window and select the straights that should be treated as Split Bends.<br><br> | ||

| + | </td> | ||

| + | <td> | ||

| + | [[image:vtube-laser_v2.2_master_with_splitbend.png|500px]] | ||

</td> | </td> | ||

</tr> | </tr> | ||

| Line 29: | Line 32: | ||

<tr valign=top> | <tr valign=top> | ||

<td width=400 > | <td width=400 > | ||

| − | Enter the Part Setup data for the new part. Especially enter the DEFAULT RADIUS. (You can measure the radius if necessary in Measure Process.) | + | Enter the Part Setup data for the new part. Especially enter the PART NUMBER and DEFAULT RADIUS. (You can measure the radius if necessary in Measure Process.) |

</td> | </td> | ||

<td width=400 > | <td width=400 > | ||

Revision as of 01:42, 4 February 2016

|

How to Reverse Engineer A Part Using Split Bend

|

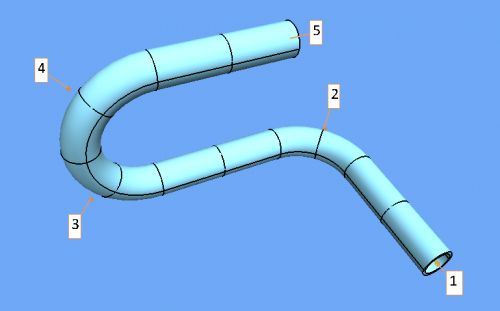

The Split Bend feature allows you to accurately measure bends that equal or exceed 180 degrees. |

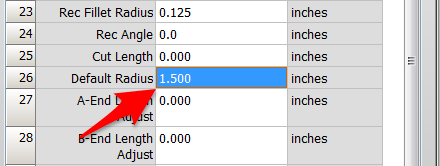

STEP 1: Enter PART SETUP Data

|

Enter the Part Setup data for the new part. Especially enter the PART NUMBER and DEFAULT RADIUS. (You can measure the radius if necessary in Measure Process.) |

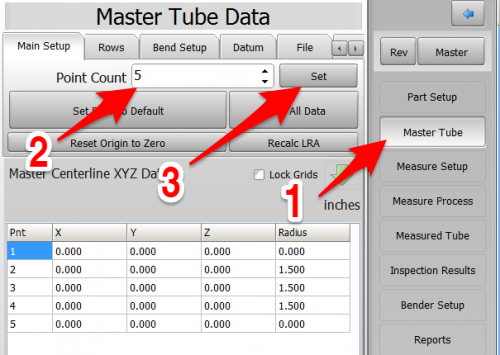

STEP 2: Populate the MASTER TUBE DATA Grid

|

Since the Split Bend feature creates a grid based on the number of straights in the MASTER data, it is important to set the number of points that you will be measuring in the reversed tube. |

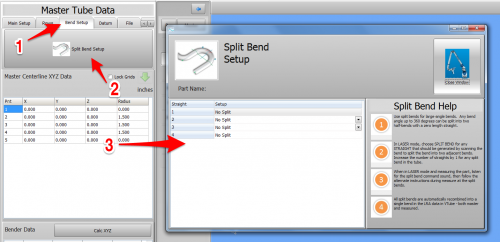

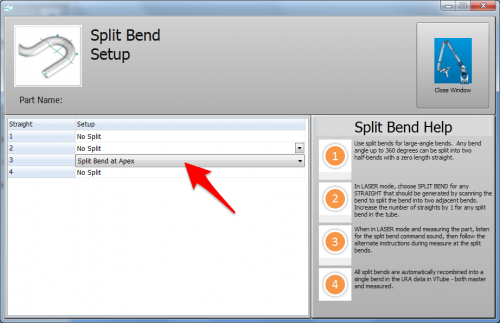

STEP 3: Configure the Split Bend Window

|

The Split Bend window is on the Bend Setup tab in the MASTER TUBE menu. Click into that window. |

|

|

In the Split Bend window, set any straight that will be treated as a Split Bend. |

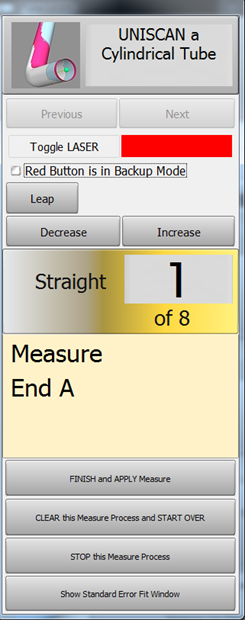

STEP 4: Measure The Part

|

This step is identical to regular reverse-engineering measuring. |

STEP 5: Choose Build Measured Tube Data Only

|

Because the MASTER data row count is greater than zero, the Measurement Complete window will offer to allow you to ALIGN the measured tube. |

|

|

The new measured tube will appear as a blue tube like this. |

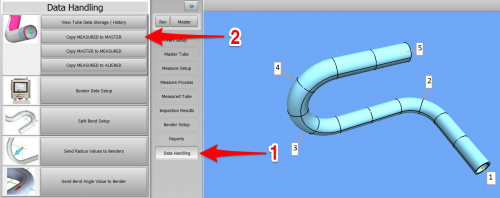

STEP 6: Copy Measured to Master

|

Copy Measured to Master Data in the Data Handling menu. This will overwrite the MASTER data ZEROS with the MEASURED tube data. |

STEP 7: Optional Reset Origin to Zero

|

Some customers prefer to translate the new MASTER data so that the first point is at 0,0,0. |

STEP 8: View the New Master Tube

|

View the new MASTER tube by switching the display of the Master tube on, then redrawing and zooming all. |

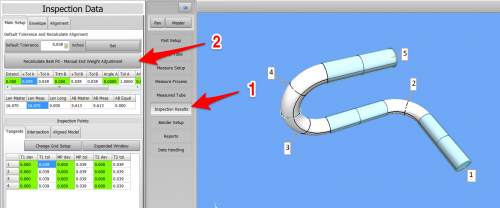

STEP 9: Optional Alignment Test

|

This is a cross-check to be sure the process was performed properly. Enter the Inspection Results menu, and press Recalculate for the alignment. |

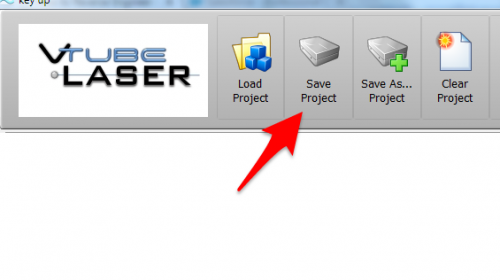

STEP 10: Save the VTube Project

|

Press the Project Save button in the Toolbar, choose the project save path and filename, and save the VTube Project file. |

Other Pages

- Back to VTube-LASER

- See also Calibration-Leapfrog-Move Targets

- Purchase the targets at the store.