Difference between revisions of "Hopper Logic"

| Line 5: | Line 5: | ||

[[image:cncbender_hopper1_diagram.jpg|500px|right]] | [[image:cncbender_hopper1_diagram.jpg|500px|right]] | ||

| − | CNC Bender Hopper Logic uses a secondary process list that runs in parallel to the main process list in order to cycle the hopper blade. There is never a need for a secondary PLC controlling the hopper.<br><br> | + | CNC Bender Hopper Logic uses a secondary process list that runs in parallel to the main process list in order to cycle the hopper blade. '''There is never a need for a secondary PLC controlling the hopper.'''<br><br> |

The diagram on the right shows the main process in the orange box on the left. This is the actual bend program process. | The diagram on the right shows the main process in the orange box on the left. This is the actual bend program process. | ||

Revision as of 22:33, 1 October 2008

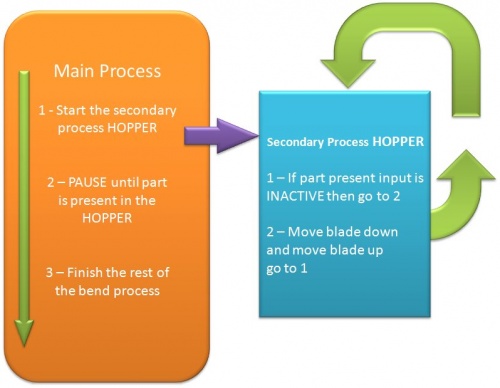

CNC Bender Hopper Logic uses a secondary process list that runs in parallel to the main process list in order to cycle the hopper blade. There is never a need for a secondary PLC controlling the hopper.

The diagram on the right shows the main process in the orange box on the left. This is the actual bend program process.

The box on the right is the secondary process called HOPPER. It causes the hopper blade to cycle up and down until a part is found with the part present input ACTIVE. (This process can be modified for your application.)

When the part is detected, then the HOPPER process no longer cycles the blade down and up.

Then the main process detects that the part detect input is ACTIVE and moves to the next step (See 3 in the orange box).