Difference between revisions of "CNC Bender Robot Integration"

From ATTWiki

(→Command Setup for Robot Type 1) |

(→Command Setup for Robot Type 1) |

||

| Line 33: | Line 33: | ||

==Command Setup for Robot Type 1== | ==Command Setup for Robot Type 1== | ||

| − | This chart shows an example of of the the command set that is used by CNC Bender to integrate to standard robots. | + | This chart shows an example of of the the command set that is used by CNC Bender to integrate to standard robots. |

| + | <blockquote> | ||

| + | (Note that the input/output point assignment is for bender 16188. The assignment may vary slightly between benders. However, the COMDEF and CIO names will remaine the same): | ||

| + | </blockquote> | ||

| + | <br><br> | ||

[[image:Cncbender_commandsetup_robot_type1.jpg]] | [[image:Cncbender_commandsetup_robot_type1.jpg]] | ||

Revision as of 14:41, 24 July 2008

CNC Bender can integrate to robots for both loading and unloading.

Logic Flow for Robot Type 1 Integration

You can view sample LOAD and UNLOAD logic here for our standard robot (type 1) integration.

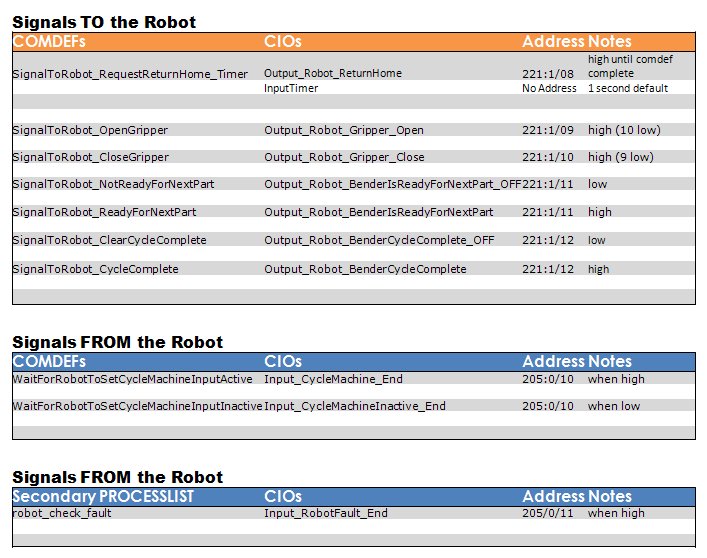

Command Setup for Robot Type 1

This chart shows an example of of the the command set that is used by CNC Bender to integrate to standard robots.

(Note that the input/output point assignment is for bender 16188. The assignment may vary slightly between benders. However, the COMDEF and CIO names will remaine the same):