Difference between revisions of "CNC Bender Low Level Menu - CNC Processor Setup"

(→Heartbeat Interval) |

|||

| (10 intermediate revisions by one user not shown) | |||

| Line 1: | Line 1: | ||

| − | [[image:Cncbender_lowlevel_processorsetup.jpg| | + | [[image:Cncbender_lowlevel_processorsetup.jpg|400px|right]] |

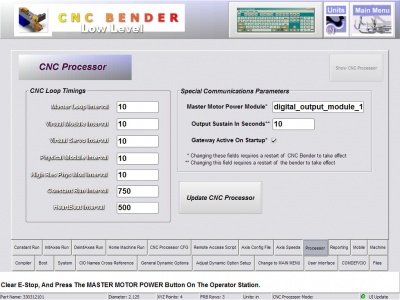

The CNC Bender Low Level Processor Menu has several values that control the timers of loops inside the processor loop. The "processor loop" is the loop that the CNC Processor performs every time it processes a list of commands. The timers control how often each event in the loop is handled. | The CNC Bender Low Level Processor Menu has several values that control the timers of loops inside the processor loop. The "processor loop" is the loop that the CNC Processor performs every time it processes a list of commands. The timers control how often each event in the loop is handled. | ||

<br><br> | <br><br> | ||

| − | + | ==High Speed Process Timers== | |

| − | + | The first 5 values are sub-processes that need to be handled more often in the loop. Each value is entered in milliseconds:<br><br> | |

| − | ==High | + | |

| − | The first 5 values are | + | |

[[image:Cncbender_lowlevel_processor_fastloops.jpg|300pcx]] | [[image:Cncbender_lowlevel_processor_fastloops.jpg|300pcx]] | ||

| + | <br><br> | ||

| + | The goal of supplying a value to these timers is to reduce the total load on the CPU by limiting how often each process is run.<br> | ||

| + | <br> | ||

| + | The value range of these timers is usually in the 5 to 10 millisecond range. Setting them to 1 is similar to turning off the timers. Making them higher may slow down the perceived response speed of the CNC Processor, but will decrease the load on the CPU. | ||

| + | |||

| + | ==Low Speed Process Timers== | ||

| + | The last two values are sub-processes that should not be called often - or they will shutdown all other processes. As with the values above, each value is entered in milliseconds:<br><br> | ||

| + | [[image:Cncbender_lowlevel_processor_slowloops.jpg|300pcx]] | ||

| + | <br><br> | ||

| + | ====Constant Run Interval==== | ||

| + | The constant run loop should always be run at least every 750 milliseconds.<br> | ||

| + | <br> | ||

| + | ====Heartbeat Interval==== | ||

| + | The heartbeat loop is the loop for the process that sends data from CNC Processor to other interfaces - like the main CNC Bender interface. For operator stations that are slower, setting this value to 500 can make a significant difference in overall performance of the bender. The reason is because of the large quantity of data sent during each heartbeat process.<br> | ||

| + | <br> | ||

| + | I recommend that you use a range of 250 to 500 milliseconds for this value. If the values from CNC Processor are updated too slowly in CNC Bender, then gradually decrease the value until the data is updated quickly enough. | ||

Latest revision as of 00:03, 28 March 2008

The CNC Bender Low Level Processor Menu has several values that control the timers of loops inside the processor loop. The "processor loop" is the loop that the CNC Processor performs every time it processes a list of commands. The timers control how often each event in the loop is handled.

Contents |

High Speed Process Timers

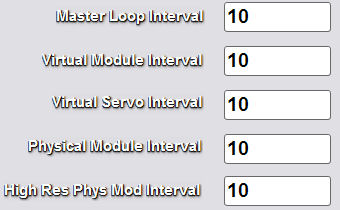

The first 5 values are sub-processes that need to be handled more often in the loop. Each value is entered in milliseconds:

The goal of supplying a value to these timers is to reduce the total load on the CPU by limiting how often each process is run.

The value range of these timers is usually in the 5 to 10 millisecond range. Setting them to 1 is similar to turning off the timers. Making them higher may slow down the perceived response speed of the CNC Processor, but will decrease the load on the CPU.

Low Speed Process Timers

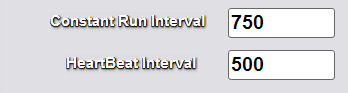

The last two values are sub-processes that should not be called often - or they will shutdown all other processes. As with the values above, each value is entered in milliseconds:

Constant Run Interval

The constant run loop should always be run at least every 750 milliseconds.

Heartbeat Interval

The heartbeat loop is the loop for the process that sends data from CNC Processor to other interfaces - like the main CNC Bender interface. For operator stations that are slower, setting this value to 500 can make a significant difference in overall performance of the bender. The reason is because of the large quantity of data sent during each heartbeat process.

I recommend that you use a range of 250 to 500 milliseconds for this value. If the values from CNC Processor are updated too slowly in CNC Bender, then gradually decrease the value until the data is updated quickly enough.