CNC Bender v12.12

v12.12 - August 25, 2014

|

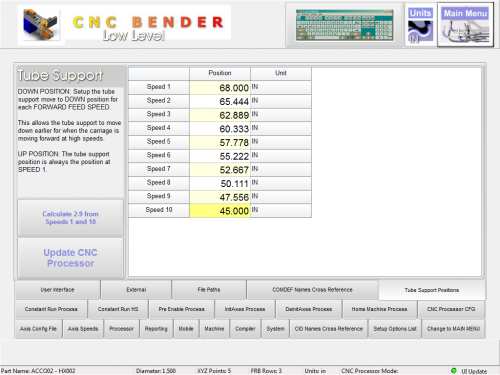

NEW: CNC Bender and CNC Processor - Tube Support Position Based on Feed Speed

NEW: CNC Bender and CNC Processor - Tube Support Position Based on Feed Speed

|

The TUBE SUPPORT POSITION logic is completely redesigned in this version. The problem in previous versions:

How this feature solves those two problems:

CIO Name Of Feed Relative Positive=MOVE_FEED_POS_RELATIVE CIO Name Of Feed Absolute=MOVE_FEED_ABSOLUTE |

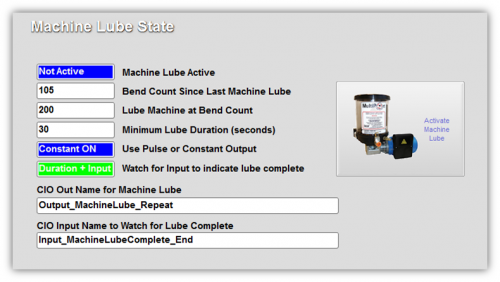

ENHANCED: CNC Processor - Machine Lube Feature

ENHANCED: CNC Processor - Machine Lube Feature

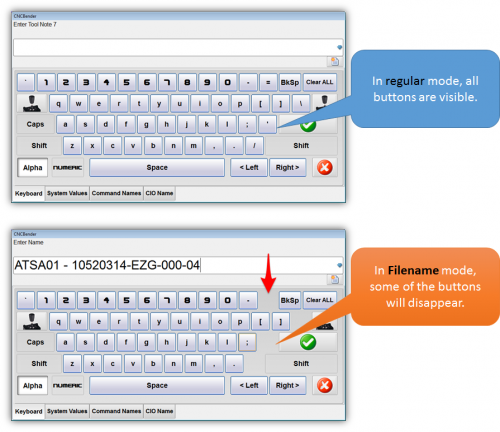

ENHANCED: Part Filename Mode in Keyboard

ENHANCED: Part Filename Mode in Keyboard

|

Previous versions of CNC Bender would allow characters in part names that made the part name illegal or caused problems to CNC Bender.

|

NEW: [Tube Support Override] Command

NEW: [Tube Support Override] Command

|

The new [Tube Support Override] processlist command is added to this version. This command can be set to ENABLE or DISABLE in order to override CNC Processor from handling the tube support automatically. An example use is to add it to the Home processlist to customize the tube support during homing. In this case, CNC Processor would stop trying to control the tube support automatically, and allow the Home process exclusive control. |

[Tube Support Override] enable [Tube Support Override] disable |

NEW: [Tube Support Position] Command

NEW: [Tube Support Position] Command

|

The new [Tube Support Position] processlist command is added to this version. This command can be followed by a linear millimeter value that indicates where the tube support should come up or go down. This new command will work with the new tube support position PER FEED AXIS SPEED support feature in this version. When the Feed axis speed changes, then the tube support process can also change per the Tube Support page in the Tool menu. CNC Bender manual page and processlists can change the position at any time to accommodate for different Feed speeds. |

[Tube Support Position] 1650.0 This would switch the tube support as the carriage passes 1650.0 millimeters from the home position. |

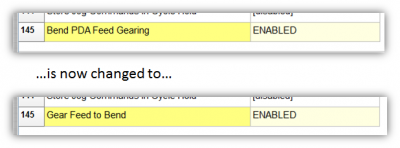

ENHANCEMENT and FIX: Gear Feed to Bend (Low Level)

ENHANCEMENT and FIX: Gear Feed to Bend (Low Level)

OPTION RENAMINGThe previous version of this option was called "Bend PDA Feed Gearing" - which was a misleading name. This option was never intended to control PDA gearing - only Feed Gearing to the bend axis. So the option name is changed to "Gear Feed to Bend" for clarity. The help file name was changed from "BendPDAFeedGearing.rtf" to "GearFeedToBend.rtf". LOGIC FIXAlso, the logic in the Processlist Builder was changed because it would assume that FEED gearing is always accompanied by PDA gearing. This isn't always the case, so the logic was changed to handle the FEED gearing with PDA standard-output actuators.

|

FIX: Option Label Order Swapped

FIX: Option Label Order Swapped

|

The previous versions showed option labels swapped so that the bottom label was on the top label. This has been repaired in this version. |

Other Changes

Other Changes

|

Other Pages

- Back to CNC Bender

- Back to CNC Bender Software Updates

- See CNC Bender Customer Service Page for an update.

- See CNC Bender General Information

- See Teach Mode

- See Custom Commands